15

6.3.

Electrical Installation

Before connecting electrical power, pay close attention to the electrical data on machine

plate. Ensure that the voltage of the power supply is compatible with that specified on

plate. All installation work must be carried out by qualified personnel. Always consult

machine tool wiring diagram before connecting power.

LOCK OUT/TAG OUT any and all power disconnect switches

before performing any work on equipment.

Be sure to observe local and federal electrical codes in effect.

Observe the technical supply conditions imposed by the power

supply company.

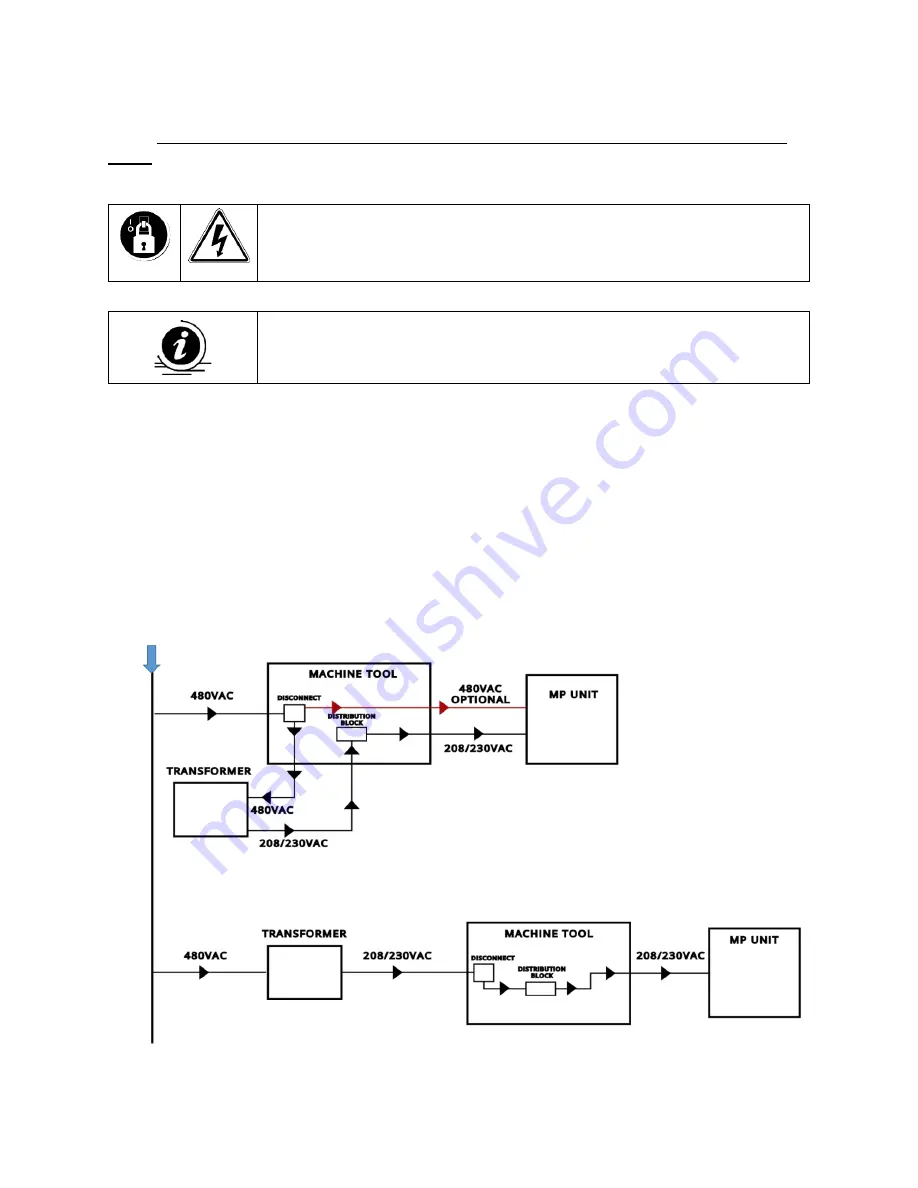

6.3.1. Selecting Voltage

Many large industrial facilities run on 480v 3phase @ 60Hz electricity. Most machine

tools in the United States require a step down transformer as the machine tools,

typically, run on 200 +/- 10% VAC.

208-230v is the standard voltage for MP Systems

units.

(Optionally, 480V units can be purchased, voltage cannot be changed in the field)

Utilizing machine tool voltage makes lockout/tag-out far easier and allows it to comply

with most local regulations.

Power can either be pulled from a separate drop, or from the machine tool using the

provided circuit breaker in the installation kit if the machine tool breaker allows.

Summary of Contents for PURGE Series

Page 15: ...10 4 3 Floor Layout ...

Page 44: ...39 10 Schematics and Diagrams 10 1 1 POWER SCHEMATIC 208 230V ...

Page 45: ...40 10 1 2 POWER SCHEMATIC 480V ...

Page 46: ...41 10 2 CONTROL SCHEMATIC ...

Page 47: ...42 10 3 FLOW DIAGRAM ...