PAGE 18 —WC-62P/S CONCRETE MIXERS — PARTS & OPERATION MANUAL — REV. #7 (06/30/05)

WC-62P/S CONCRETE MIXER — ELECTRIC MOTOR

Electric Motor

For maintenance care and operation of the electric motor, refer

to your electric motor instruction booklet furnished with the electric

motor.

Protect the electric motor from dust as much as possible and

keep ventilating openings clean.

The electric motor used in this mixer is a single-phase 1.5 HP

motor. The input voltage requirement for this motor is either 115

or 230 VAC only.

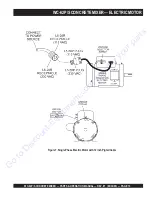

Electric Motor Connection

A 12 inch electrical cable (Figure 2) with a pigtail at one end is

provided with the electrical motor for hookup to a power source.

Table 1. shows the required NEMA connector for the desired

motor horsepower rating. In addition, Table 2 also shows the

matching NEMA approved connector for the required extension

cord.

ALWAYS, make certain that the power source required for the

electric motor is

correct and always use the correct NEMA

configuration plug.

Failure to supply the correct voltage to the

motor can severely damage the motor.

The electric motor supplied with the mixer is configured from the

factory for 115 VAC grounded operation. Make certain that the correct

size grounded (3-wires) extension cord is used. See Table 5.

Motors can burn out when the line voltage falls 10% below the

voltage rating of the motor. Failure to use proper voltage will

cause the motor to overheat and actuate the overload switch.

If overload protection should actuate because of improper voltage

or any other malfunction, turn the main switch on the motor to the

"OFF" position and correct the problem, press the reset switch

button, and turn the main switch to the "ON" position.

CAUTION:

■

DO NOT spray water at any time on the

electric motor.

■

DO NOT operate electric motor in a

explosive environment.

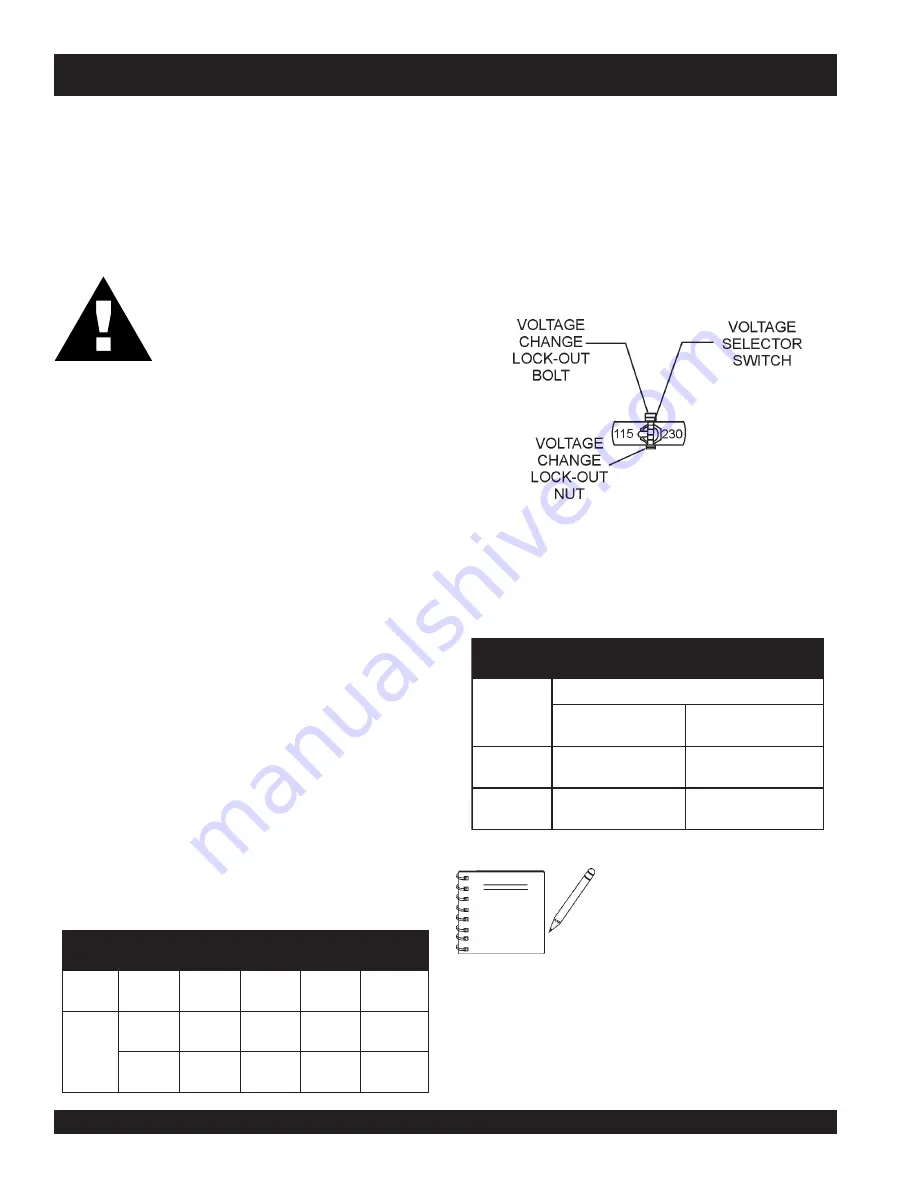

Electric Motor Voltage Change Switch

1.

ALWAYS make certain the electric motor's ON/OFF switch

is in the "OFF" position and the power cord has been

disconnected from the power source.

2.

Remove the voltage change lock-out bolt and nut

(Figure 6).

Change the position of the

voltage change toggle switch

from 115 VAC to 230 VAC. The mixer is factory wired for 115

VAC operation.

3.

Re-install the voltage change lock-out bolt and nut.

NOTE

NEVER!

disable or disconnect the

ON/OFF switch on the electric motor.

It is provided for operator safety. Injury

may result if it is disable, disconnected

or improperly maintained.

Figure 6. Voltage Change Switch

4.

Important!, when changing the input voltage to the electric

motor from 115 to 230 VAC, the

plug on the electric motor

power cord must also be changed. See Table 6 and Figure 7.

e

z

i

S

d

r

o

C

n

o

i

s

n

e

t

x

E

d

e

d

n

e

m

m

o

c

e

R

.

5

e

l

b

a

T

sssss

c

i

r

t

c

e

l

E

r

o

t

o

M

t

u

p

n

I

e

g

a

t

l

o

V

.

t

f

0

5

)

m

4

2

.

5

1

(

.

t

f

5

7

)

m

6

8

.

2

2

(

.

t

f

0

0

1

)

m

8

4

.

0

3

(

.

t

f

0

0

2

)

m

6

9

.

0

6

(

P

H

5

.

1

C

A

V

5

1

1

2

1

.

o

N

0

1

.

o

N

8

.

o

N

6

.

o

N

C

A

V

0

3

2

4

1

.

o

N

2

1

.

o

N

2

1

.

o

N

8

.

o

N

n

o

i

t

a

m

r

o

f

n

I

g

n

i

r

i

W

r

o

t

o

M

c

i

r

t

c

e

l

E

.

6

e

l

b

a

T

r

o

t

o

M

r

e

w

o

p

e

s

r

o

H

g

n

i

t

a

R

e

s

a

h

P

e

l

g

n

i

S

-

C

A

V

0

3

2

-

5

1

1

r

o

t

c

e

n

n

o

C

g

u

l

P

A

M

E

N

A

M

E

N

g

n

i

t

a

M

r

o

t

c

e

n

n

o

C

e

l

c

a

t

p

e

c

e

R

P

H

5

.

1

)

C

A

V

5

1

1

(

7

3

5

0

4

9

M

E

N

/

P

P

0

2

-

5

L

8

3

5

0

4

9

M

E

N

/

P

R

0

2

-

5

L

P

H

5

.

1

)

C

A

V

0

3

2

(

9

3

5

0

4

9

N

/

P

P

0

2

-

6

L

0

4

5

0

4

9

N

/

P

R

0

2

-

6

L

Go to Discount-Equipment.com

to order your parts