DCA-150SSJU — PARTS AND OPERATION MANUAL — REV. #3 (09/07/01) — PAGE 47

DCA-150SSJU — PRE-SETUP

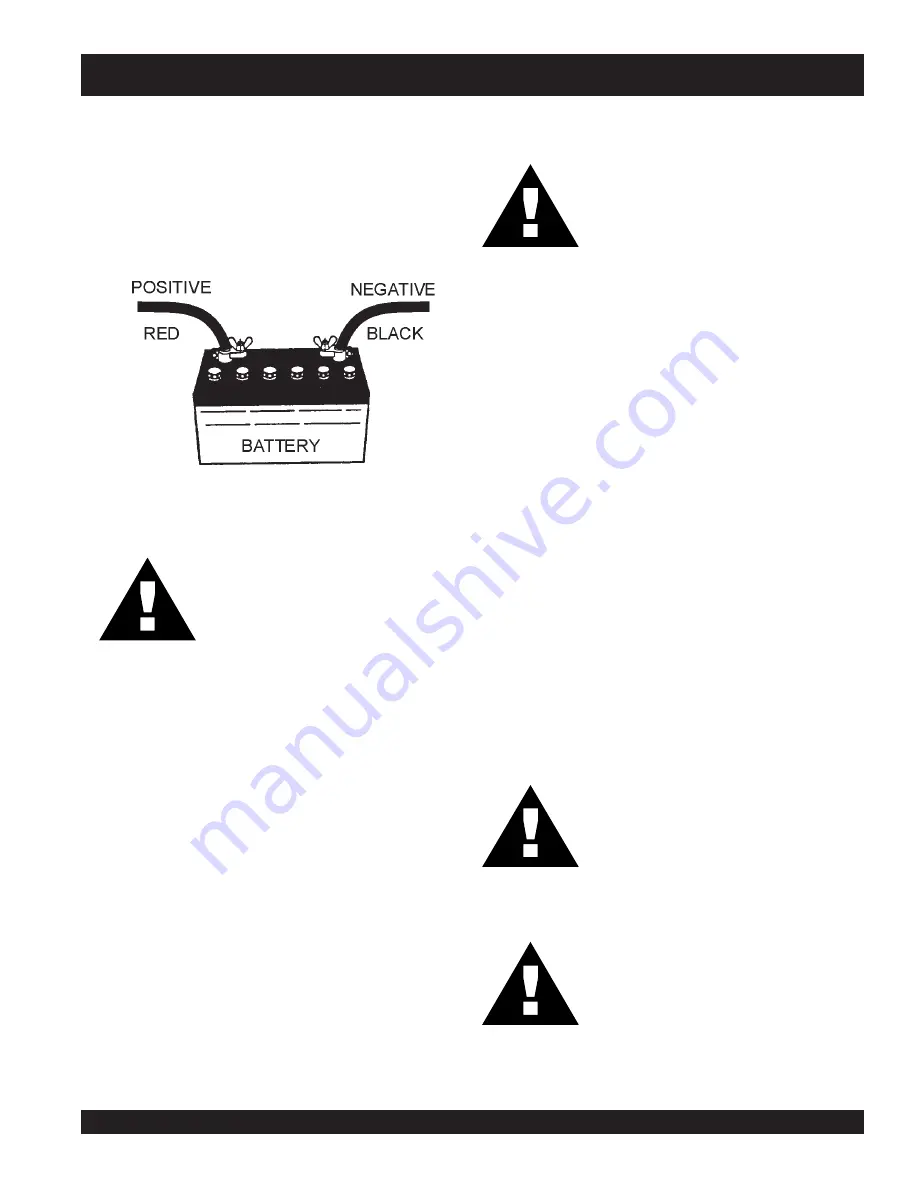

Battery Cable Installation

ALWAYS

be sure the battery cables (Figure 41) are properly

connected to the battery terminals as shown below. The

RED

cable is connected to the positive terminal of the battery,

and the

BLACK

cable is connected to the negative terminal

of the battery.

Before connecting battery do the following:

1a.

DO NOT

connect the battery cables to the battery

terminals when the

Off/Manual/Auto

switch is in either

the manual or auto position (ON) if the generator is

installed with a microprocessor engine controller.

ALWAYS

make sure that the Off/Manual/Auto switch is

in the “OFF” position when connecting the battery.

1b. If the generator is equipped with an ignition switch, make

sure turned to the “OFF” position and the key is removed

from the switch.

2. Place a small amount of grease around both battery

terminals. This will ensure a good connection and will

help prevent corrosion around the battery terminals.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

:

Inadequate battery connections may cause

poor starting of the generator, and create

other malfunctions.

Wiring

Inspect the entire generator for bad or worn electrical wiring

or connections. If any wiring or connections are exposed

(insulation missing) replace wiring immediately.

Piping and Hose Connection

Inspect all piping, oil hose, and fuel hose connections for

wear and tightness. Tighten all hose clamps and check hoses

for leaks.

If any hose (fuel or oil) lines are defective replace them

immediately.

Ether Canister Operation (During Cold Conditions)

To bleed the ether, crank the engine for at least two

revolutions, then momentarily depress the starting aid button

while the engine is cranking. If the engine does not start,

repeat the cranking process using only short bursts of ether

only while the engine is cranking. Stop injecting the fluid

after then engine starts. If the engine begins to die during

the first few minutes of operation, inject another small shot

of ether.

Figure 41. Battery Connections

If the battery cable is connected

incorrectly, electrical damage to the

generator will occur. Pay close attention

to the polarity of the battery when

connecting the battery.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

:

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

:

Use only ether starting fluid while the

engine is turning or damage may occur.

WARNING

WARNING

WARNING

WARNING

WARNING

:

Ether is highly flammable. Do not use

near open fires, flames, or sparks.

Summary of Contents for DCA-150SSJU

Page 2: ...PAGE 2 DCA 150SSJU PARTS AND OPERATION MANUAL REV 3 09 07 01 ...

Page 22: ...PAGE 22 DCA 150SSJU PARTS AND OPERATION MANUAL REV 3 09 07 01 DCA 150SSJU GENERATOR DECALS ...

Page 25: ...DCA 150SSJU PARTS AND OPERATION MANUAL REV 3 09 07 01 PAGE 25 NOTE PAGE ...

Page 99: ...DCA 150SSJU PARTS AND OPERATION MANUAL REV 3 09 07 01 PAGE 99 NOTE PAGE ...