DCA1100SSC 60 HZ GENERATOR • OPERATION MANUAL — REV. #1 (01/17/18) — PAGE 43

RADIATOR CLEANING

The radiator (Figure 61) should be sprayed (cleaned) with

a high pressure washer when excessive amounts of dirt

and debris have accumulated on the cooling fins or tube.

When using a high pressure washer, stand at least 5 feet

(1.5 meters) away from the radiator to prevent damage to

the fins and tube.

Figure 61. Radiator Cleaning

FUEL WATER SEPARATOR

1. To

OPEN the drain valve on the fuel water separator

turn the knob

counterclockwise

(Figure 62

A)

approximately 3-1/2 turns until the valve drops down

1-inch (25.4 mm) and draing occurs(Figure 62

B).

Figure 62. Fuel Water Separator

FUEL FILTER/

WATER

SEPARATOR

OPEN

DRAIN

CLOSE

A

B

C

OPEN/CLOSE

KNOB

2. Continue draining until fuel is clear.

3. To

CLOSE the drain valve on the fuel water separator

turn knob

clockwise

(Figure 62

C).

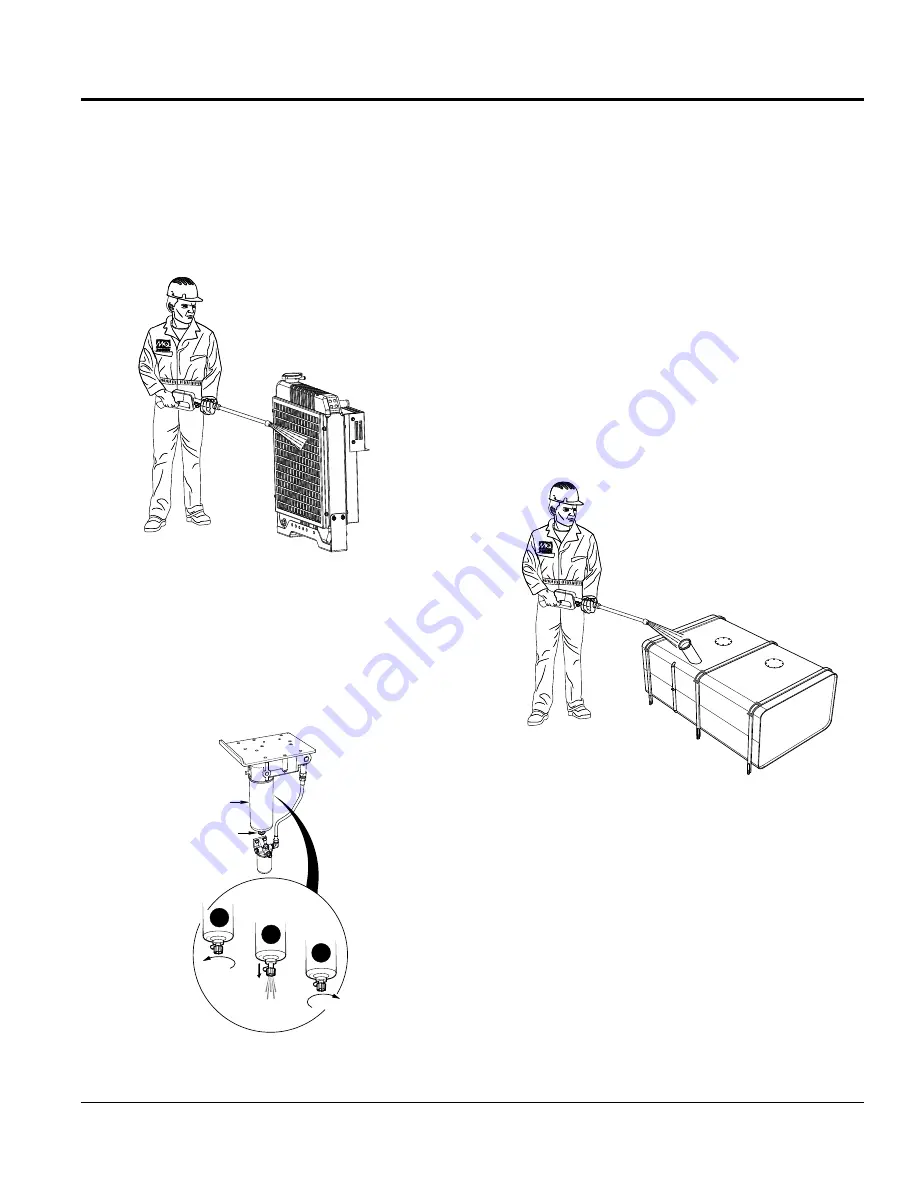

REMOVING WATER FROM THE FUEL TANK

After prolonged use, water and other impurities accumulate

in the bottom of the tank. Occasionally inspect the fuel tank

for water contamination and drain the contents if required.

During cold weather, the more empty volume inside the

tank, the easier it is for water to condense. This can be

reduced by keeping the tank full with diesel fuel.

CLEANING INSIDE THE FUEL TANK

If necessary, drain the fuel inside the fuel tank completely.

Using a spray washer (Figure 63) wash out any deposits

or debris that have accumulated inside the fuel tank.

Figure 63. Fuel Tank Cleaning

FUEL TANK INSPECTION

In addition to cleaning the fuel tank, the following

components should be inspected for wear:

Rubber Suspension — look for signs of wear or

deformity due to contact with oil. Replace the rubber

suspension if necessary.

Fuel Hoses — inspect nylon and rubber hoses for signs

of wear, deterioration and hardening.

Fuel Tank Lining — inspect the fuel tank lining for signs

of excessive amounts of oil or other foreign matter.

FUEL

TANK

MAINTENANCE