DCA-300SSK SERIES — PARTS AND OPERATION MANUAL (STD)— REV. #4 (03/27/06) — PAGE 35

Coolant (Ethylane Glycol [Green] / Water — 50/50 mix)

Use only drinkable tap water. If hard water or water with

many impurities is used, the inside of the engine and radiator

may become coated with deposits and cooling efficiency

will be reduced.

An anticorrosion additive added to the water will help prevent

deposits and corrosion in the cooling system. See the engine

manual for further details.

Day-to-day addition of coolant is done from the recovery

tank. When adding coolant to the radiator,

DO NOT

remove

the radiator cap until the unit has completely cooled. See

Table 11 for engine and radiator, coolant capacities. Make

sure the coolant level in the recovery tank is always between

the "

H

" and the "

L

" markings.

Operation Freezing Weather

When operating in freezing weather, be certain the proper

amount of antifreeze (Table 12) has been added.

Cleaning the Radiator

The engine may overheat if the radiator fins become

overloaded with dust or debris. Periodically clean the radiator

fins with compressed air. Cleaning inside the machine is

dangerous, so clean only with the engine turned off and the

negative

battery terminal disconnected.

Air Cleaner

Periodic cleaning/replacement is necessary. Inspect it in

accordance with the

Komatsu Engine Owner's Manual.

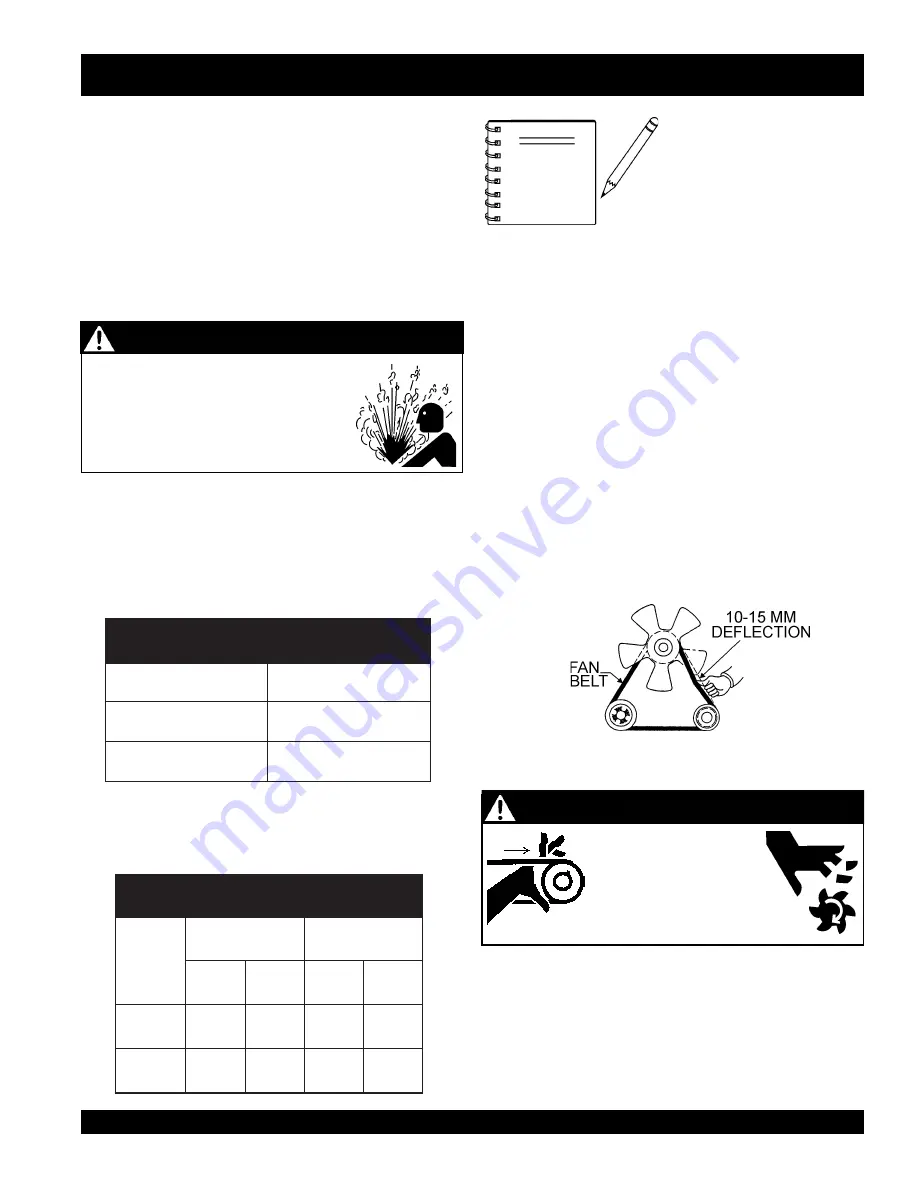

Fan Belt Tension

A slack fan belt may contribute to overheating, or to

insufficient charging of the battery. Inspect the fan belt for

damage and wear and adjust it in accordance with the

Komatsu Engine Owner's Manual.

The fan belt tension is proper if the fan belt bends 10 to 15

mm (Figure 38) when depressed with the thumb as shown

below.

Figure 38. Fan Belt Tension

DCA-300SSK SERIES — PRE-SETUP

When the antifreeze is mixed with

water, the antifreeze mixing ratio

must be

less than 50%.

NOTE

y

t

i

c

a

p

a

C

t

n

a

l

o

o

C

.

1

1

e

l

b

a

T

e

p

y

T

e

n

i

g

n

E

y

t

i

c

a

p

a

C

t

n

a

l

o

o

C

2

-

E

5

2

1

D

6

A

S

u

s

t

a

m

o

K

)

s

r

e

ti

L

6

.

2

3

(

.l

a

G

5

.

8

2

-

E

5

2

1

D

6

A

A

S

u

s

t

a

m

o

K

)

s

r

e

ti

L

0

.

7

3

(

.l

a

G

8

.

9

s

e

r

u

t

a

r

e

p

m

e

T

g

n

i

t

a

r

e

p

O

e

z

e

e

r

F

-

i

t

n

A

.

2

1

e

l

b

a

T

%

l

o

V

e

z

e

e

r

F

-i

t

n

A

t

n

i

o

P

g

n

i

z

e

e

r

F

t

n

i

o

P

g

n

il

i

o

B

C

°

F

°

C

°

F

°

0

4

4

2

-

2

1

-

6

0

1

2

2

2

0

5

7

3

-

4

3

-

8

0

1

6

2

2

If adding coolant/antifreeze mix to the

radiator,

DO NOT

remove the radiator cap

until the unit has completely cooled. The

possibility of

hot!

coolant exists which

can cause severe burns.

WARNING - BURN HAZARDS

NEVER

place hands near

the belts or fan while the

generator set is running.

CAUTION - ROTATING PARTS