DCA-60SSAI — PARTS AND OPERATION MANUAL— FINAL COPY (09/15/01) — PAGE 23

DCA-60SSAI — SPECIFICATIONS

s

n

o

it

a

c

if

i

c

e

p

S

.

7

e

l

b

a

T

s

n

o

it

a

c

if

i

c

e

p

S

r

o

t

a

r

e

n

e

G

l

e

d

o

M

2

I

S

S

0

6

-

A

C

D

e

p

y

T

r

o

t

a

r

e

n

e

g

s

u

o

n

o

r

h

c

n

y

s

e

p

y

t

d

e

t

c

e

t

o

r

p

n

e

p

o

,

d

e

t

a

li

t

n

e

v

fl

e

s

,

d

l

e

if

g

n

i

v

l

o

v

e

R

n

o

it

c

e

n

n

o

C

e

r

u

t

a

m

r

A

l

a

r

t

u

e

N

h

t

i

w

r

a

t

S

g

a

Z

g

i

Z

e

s

a

h

P

3

e

l

g

n

i

S

t

u

p

t

u

O

y

b

d

n

a

t

S

)

W

K

6

.

7

5

(

A

V

K

2

7

W

K

5

.

1

4

t

u

p

t

u

O

e

m

ir

P

)

W

K

8

4

(

A

V

K

0

6

W

K

6

.

4

3

e

g

a

tl

o

V

V

0

8

4

r

o

V

0

4

2

V

0

2

1

/

0

4

2

y

c

n

e

u

q

e

r

F

z

H

0

6

d

e

e

p

S

m

p

r

0

0

8

1

r

o

t

c

a

F

r

e

w

o

P

8

.

0

1

r

e

w

o

P

C

A

.

x

u

A

z

H

0

6

,

e

s

a

h

P

e

l

g

n

i

S

e

g

a

tl

o

V

V

0

2

1

t

u

p

t

u

O

)

2

x

W

K

4

.

2

(

W

K

8

.

4

s

n

o

it

a

c

if

i

c

e

p

S

e

n

i

g

n

E

l

e

d

o

M

1

G

B

6

-

A

U

Z

U

S

I

e

p

y

T

n

o

it

c

e

j

n

i

t

c

e

ri

d

,

d

e

l

o

o

c

-

r

e

t

a

w

,

e

l

c

y

C

4

s

r

e

d

n

il

y

C

f

o

.

o

N

s

r

e

d

n

il

y

c

6

e

k

o

r

t

S

x

e

r

o

B

)

m

m

5

2

1

x

m

m

5

0

1

(

.

n

i

9

.

4

x

.

n

i

1

.

4

t

u

p

t

u

O

d

e

t

a

R

m

p

r

0

0

8

1

/

P

H

7

7

t

n

e

m

e

c

a

l

p

s

i

D

)

c

c

4

9

4

6

(

.

n

i

.

u

c

6

9

3

g

n

it

r

a

t

S

c

ir

t

c

e

l

E

y

ti

c

a

p

a

C

t

n

a

l

o

o

C

)

s

r

e

ti

l

5

.

9

2

(

.l

a

g

8

.

7

y

ti

c

a

p

a

C

li

O

e

b

u

L

)

s

r

e

ti

l

3

.

9

1

(

.l

a

g

1

.

5

n

o

it

p

m

u

s

n

o

C

l

e

u

F

t

a

r

h

/

)

L

9

.

4

1

(

.l

a

g

9

.

3

d

a

o

l

ll

u

f

t

a

r

h

/

)

L

4

.

1

1

(

.l

a

g

0

.

3

d

a

o

l

4

/

3

t

a

r

h

/

)

L

1

.

9

(

.l

a

g

4

.

2

d

a

o

l

2

/

1

t

a

r

h

/

)

L

2

.

7

(

.l

a

g

9

.

1

d

a

o

l

4

/

1

y

r

e

tt

a

B

2

x

H

A

0

0

1

-

V

2

1

l

e

u

F

l

e

u

F

l

e

s

e

i

D

2

#

Summary of Contents for WHISPERWATT DCA-60SSAI

Page 2: ...PAGE 2 DCA 60SSAI PARTS AND OPERATION MANUAL FINAL COPY 09 15 01 ...

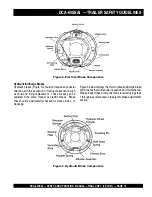

Page 22: ...PAGE 22 DCA 60SSAI PARTS AND OPERATION MANUAL FINAL COPY 09 15 01 DCA 60SSAI GENERATOR DECALS ...

Page 27: ...DCA 60SSAI PARTS AND OPERATION MANUAL FINAL COPY 09 15 01 PAGE 27 NOTE PAGE ...

Page 51: ...DCA 60SSAI PARTS AND OPERATION MANUAL FINAL COPY 09 15 01 PAGE 51 NOTE PAGE ...

Page 61: ...DCA 60SSAI PARTS AND OPERATION MANUAL FINAL COPY 09 15 01 PAGE 61 NOTE PAGE ...

Page 151: ...DCA 60SSAI PARTS AND OPERATION MANUAL FINAL COPY 09 15 01 PAGE 151 NOTE PAGE ...