Summary of Contents for WHISPERWATT DCA125SSIU

Page 19: ...DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 PAGE 19 NOTES ...

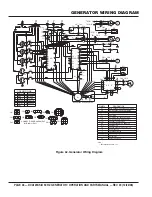

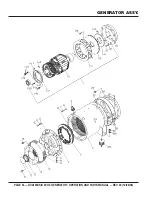

Page 54: ...PAGE 54 DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 GENERATOR ASSY ...

Page 56: ...PAGE 56 DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 CONTROL BOX ASSY ...

Page 58: ...PAGE 58 DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 CONTROL BOX ASSY ...

Page 60: ...PAGE 60 DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 CONTROL BOX ASSY ...

Page 68: ...PAGE 68 DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 BATTERY ASSY ...

Page 70: ...PAGE 70 DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 MUFFLER ASSY ...

Page 72: ...PAGE 72 DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 FUEL TANK ASSY ...

Page 87: ...DCA125SSIU 50 HZ GENERATOR OPERATION AND PARTS MANUAL REV 0 12 22 08 PAGE 87 NOTES ...