PAGE 20 — DCA300SSJU4F2 60 HZ GENERATOR • OPERATION MANUAL — REV. #0 (06/26/18)

MAJOR COMPONENTS

300

U

V

W

W

6

300

Denyo

OFF

W

U

V

OFF

W-U

V-W

U-V

DECREASE

INCREASE

Engine Started

Shutdown

Pre-Alarm

Series 800 Controller

Alarm

Acknowledge

Screen

Change

Program/

Exit

Option

ECU

PSI

OIL PRESS

0

25

50

75

100

°F

WATER TEMP

100

140

180

220

260

°F

FUEL

E

½

F

RPMX10

SPEED

0

120

150

180

210

60

°F

DEF

E

½

F

ECU

Integrated Gauge Panel

VOLTS

0

12

18

24

30

%

0

50

100

Check

DEF

Emissions

Failure

Emissions

Failure

Regen

Needed

Regen

Inhibit

Low

Fuel

10

12

7

8 9

1

2

3

4

5

11

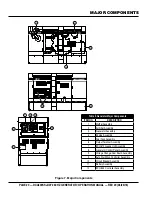

Table 5. Generator Major Components

ITEM NO.

DESCRIPTION

1

Muffler Assembly

2

Air Filter Assembly

3

Generator Assembly

4

Engine Assembly

5

Fuel Tank Assembly

6

Output Terminal Assembly

7

ECU-670 Gauge Unit Assembly

8

Generator Control Panel Assembly

9

Voltage Change-Over Board Assembly

9

Auto Start/Stop Controller Assembly

10

Circuit Breaker Assembly

11

Battery Assembly

12

ECU-845 Controller Assembly

Figure 7. Major Components