9 Visualization

Maschinenfabrik Reinhausen GmbH 2020

179

6385142/08 EN

ETOS

®

ED

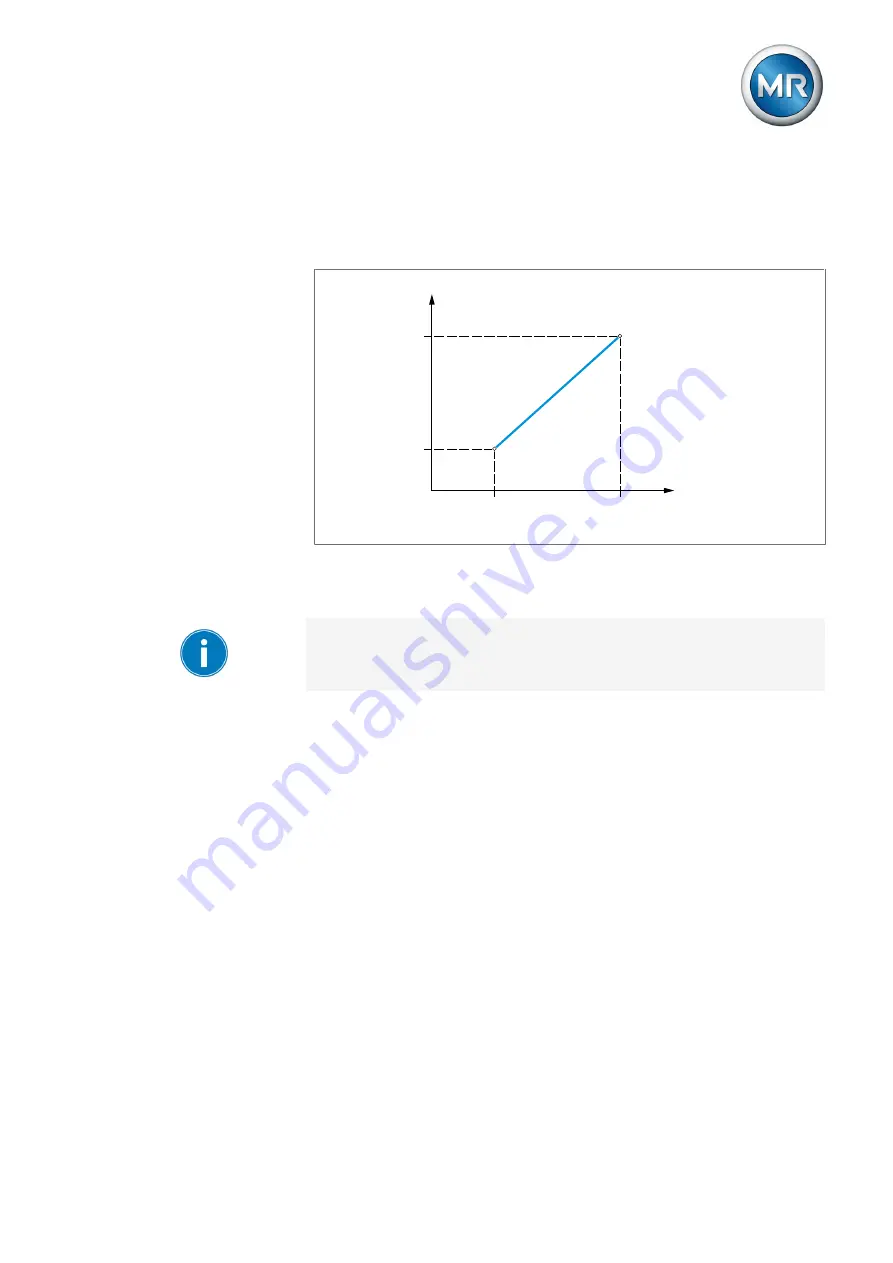

9.16.1.4 Analog setting of the desired value

With the analog setting of the desired value, the desired value for the auto-

matic voltage regulation can be variably adapted using an analog signal (e.g.

4...20 mA).

Max.

Min.

Desired value

Max.

Min.

Analog signal

Figure 132: Analog setting of the desired value

In order to configure the analog setting of the desired value, you can set the

parameters as described below.

To specify the desired value using an analog signal, you need to create a

signal at the

Desired value setting release

input. If this is not done, the de-

vice uses the set desired value 1.

Setting desired value 1

1. Go to

Settings > Parameters > Grid > Control > Desired value

.

2. Enter the desired value.

3. Press the

Accept

button to save the modified parameter.

Setting max. desired value setting

With this parameter, you can set the desired value that corresponds to the

maximum level of the analog signal level (e.g. 20 mA for 4...20 mA signal).

1. Go to

Settings > Parameters > Control > Setting max. desired value

.

2. Enter desired value.

3. Press the

Accept

button to save the modified parameter.

Setting min. desired value setting

With this parameter, you can set the desired value that corresponds to the

minimum level of the analog signal (e.g. 4 mA for 4...20 mA signal).

1. Go to

Settings > Parameters > Control > Setting min. desired value

.

2. Enter desired value.