10 Technical data

Maschinenfabrik Reinhausen GmbH 2016

25

4489615/01 EN

TAPMOTION® TD ISM®

Technical data

Dimensions and weight

Dimensions (W x H x D)

265 x 315 x 198 mm

Weight

1.7 kg

Table 10: Dimensions and weight

Electrical connection loads

Power supply

400 VAC

Frequency

50/60 Hz

Power consumption

approx. 4 A

Fuse

Miniature circuit breaker 1.6 A type

C

Motor protective switch, depending

on the setting of the gear motor's

rated current

Table 11: Electrical connection loads

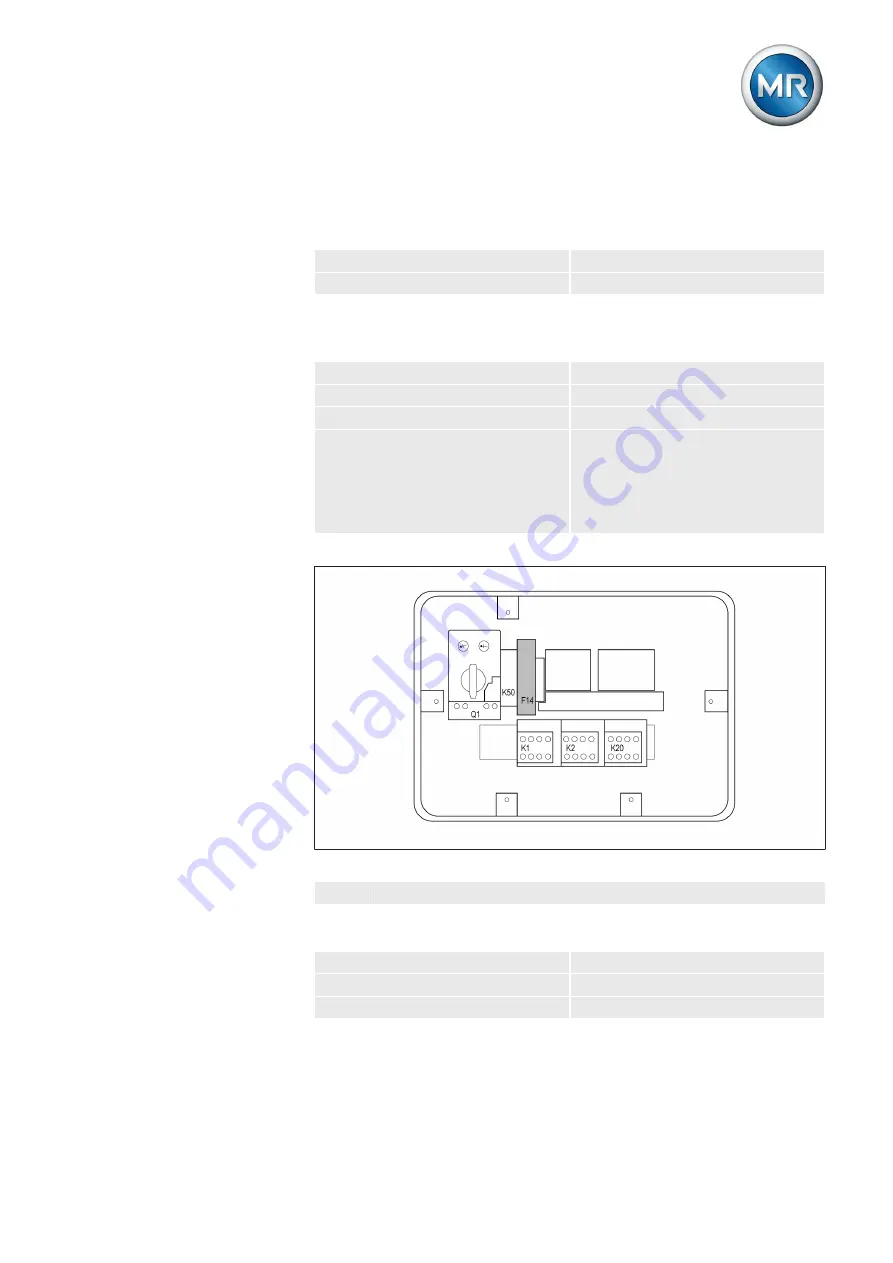

Figure 4: Position of the miniature circuit breaker if cover plate is disassembled

F14

Miniature circuit breaker

Ambient conditions

Degree of protection

IP65 (if cover closed)

Operating temperature

5...40 °C

Storage temperature

-20…+50 °C

Table 12: Ambient conditions

10

Summary of Contents for TAPMOTION TD ISM

Page 1: ...Motor drive Unit TAPMOTION TD ISM Operating Instructions 4489615 01 EN OEM Control Box ...

Page 26: ......

Page 27: ......