2 Safety

Maschinenfabrik Reinhausen GmbH 2020

20

4983703/01 EN

VACUTAP

®

VV-Ex

2.5.2.4 Corrosion protection measures

Because further installation steps are required before operation of the on-

load tap-changer, sufficient corrosion protection cannot be provided at cer-

tain interfaces to the transformer when the device leaves the factory.

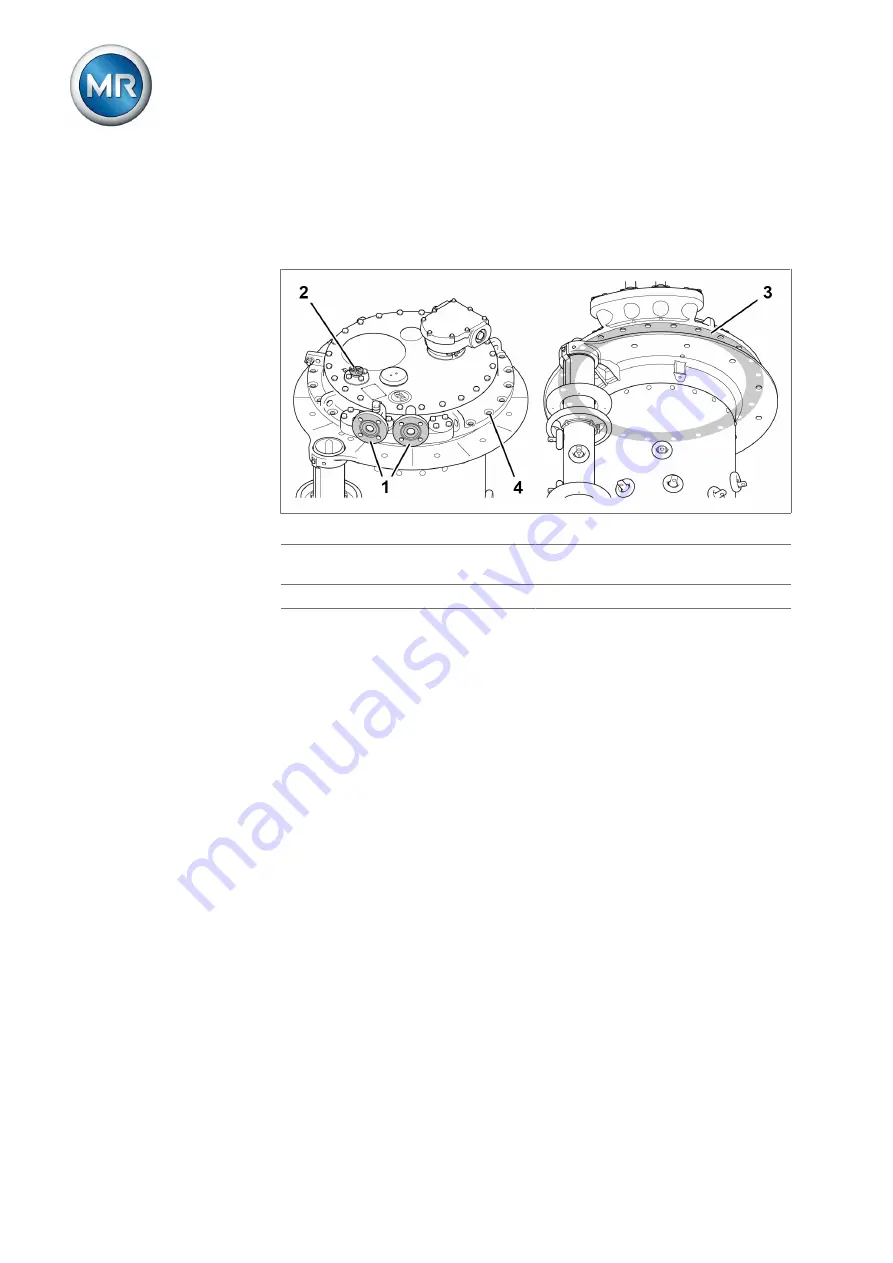

Figure 2: On-load tap-changer head

1 Sealing surface on piping connec-

tion flange

3 Contact surface on on-load tap-

changer head

2 Air-vent valve

4 Through-holes

The sealing surfaces on the piping connection flange are zinc-plated ex fac-

tory. The through-holes are zinc-plated and partially painted.

The contact surface of the on-load tap-changer head is primed ex factory.

The through-holes are primed and partially painted.

The transformer manufacturer is responsible for the design of the mating

surfaces on the transformer and piping and that of the screw connections

needed for these attachments.

1. Provide suitable sealing to prevent electrolytes from entering sealing sur-

faces and holes.

2. Design screws, washers, nuts etc. in A4 in accordance with ISO 3506-1/

ISO 3506-2 standard.

3. If the painted surfaces are damaged, note repair instructions. These can

be requested from Maschinenfabrik Reinhausen GmbH's Technical Ser-

vice department.

2.6 Personnel qualification

The person responsible for assembly, commissioning, operation, mainte-

nance and inspection must ensure that the personnel are sufficiently quali-

fied.