5 Mounting

Maschinenfabrik Reinhausen GmbH 2020

63

4983703/01 EN

VACUTAP

®

VV-Ex

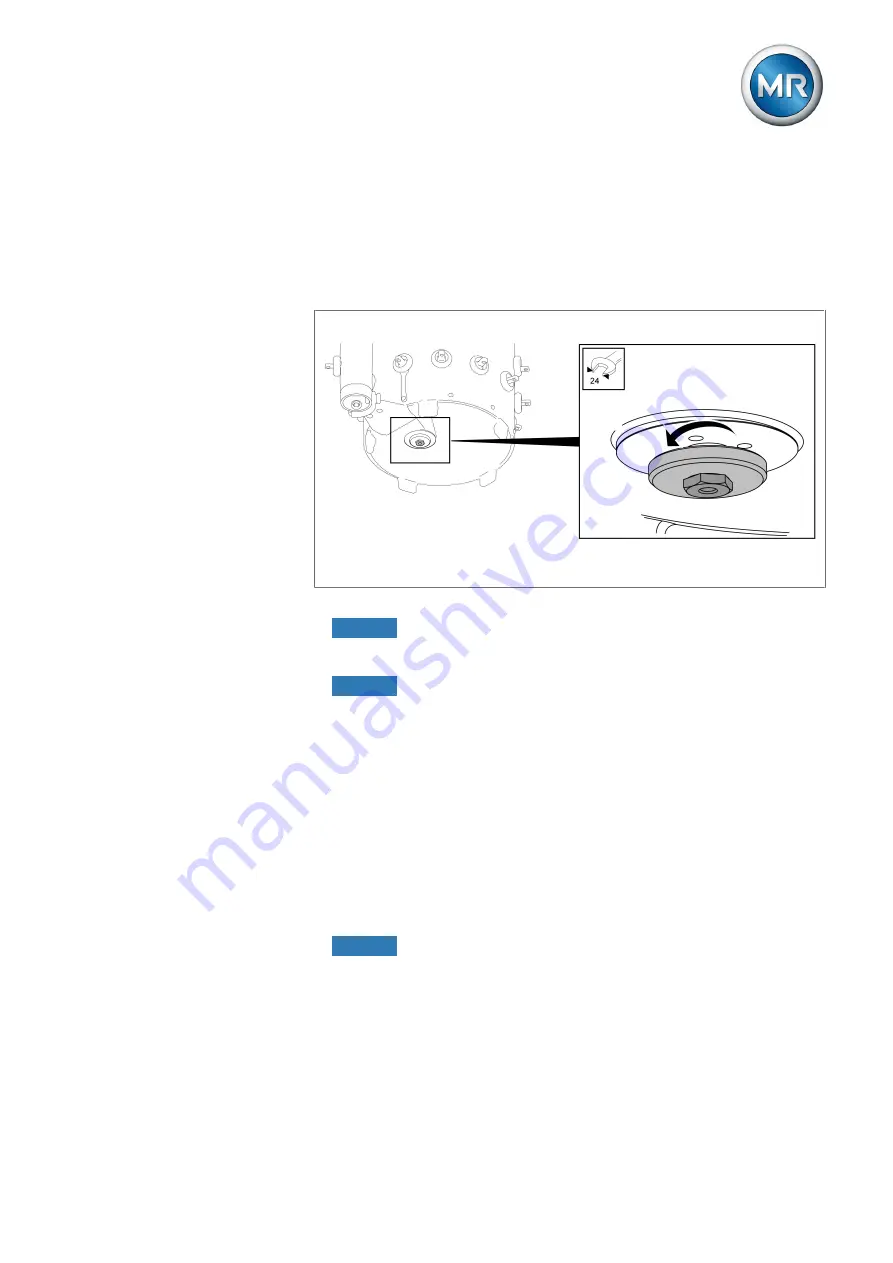

5.4.5.2 Vapor-phase drying in the autoclave

For vapor-phase drying in the autoclave, you must open the kerosene drain

plug in the oil compartment base before drying so that the kerosene conden-

sate can drain from the oil compartment.

1. Unscrew kerosene drain plug in base of oil compartment counter-clock-

wise. The kerosene drain plug cannot be unscrewed all the way.

Figure 36: Kerosene drain plug

2.

NOTICE!

Remove the on-load tap-changer head cover (24 screws M10/

wrench size 17 with locking washers) and store it outside the autoclave. If

this is not done, the on-load tap-changer head cover may be damaged.

3.

NOTICE!

Remove on-load tap-changer accessories and store outside au-

toclave: motor-drive unit, drive shaft, protective relay, bevel gear, temper-

ature sensor. If this is not done, the on-load tap-changer accessories may

be damaged.

Vapor-phase drying in the autoclave

1. Supply kerosene vapor at a temperature of around 90°C. Keep this tem-

perature constant for 3 to 4 hours.

2. Increase the kerosene vapor temperature by approx. 10°C/hour to the de-

sired final temperature of max. 125°C at the on-load tap-changer.

3. Vacuum-dry on-load tap-changer at between 105°C and maximum 125°C

for at least 50 hours.

4. Residual pressure of no more than 10

-3

bar.

►

NOTICE!

Close kerosene drain plug clockwise (tightening torque 39 Nm).

An open kerosene drain plug leads to oil escaping from the oil compart-

ment and therefore to damage to the on-load tap-changer and trans-

former.