Specifications and Features

Input:

15-16 volts DC, 3.5 Amps. It comes with a universal switching

power supply (good for USA and Europe).

Output:

DCC signal with 14.5 V amplitude, for HO and N scales

Scales larger than HO may need a power booster, such as MRC’s

Power Station 8

Maximum Current:

3.5 Amps

Maximum number of Cabs:

Use up to 99 Cabs (see page 2-4)

Address Capability:

2-digit (1-127) or 4-digit (1-9,999)

Speed Steps:

14/28/128

Accessory Functions:

28 (F0-F28)

Advanced and Universal Consisting

Program Loco on Program Track

Program Loco on Main Track

Read Loco on Program Track

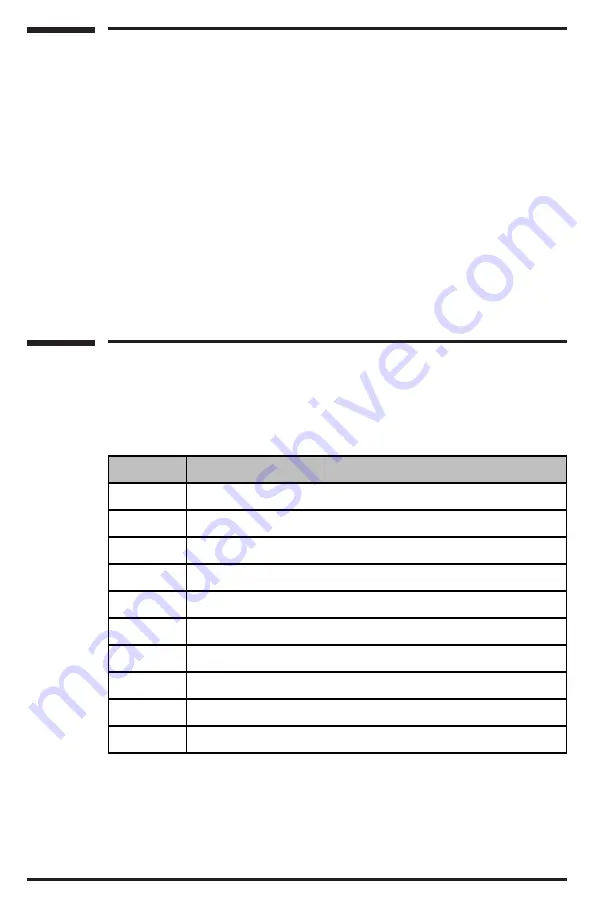

System Menu Summary Chart

Most functions are initiated by pressing their associated keys. However,

there are ten functions initiated by pressing the

SYS

key followed by a

numeric key

(0-9)

. The following table summarizes these ten functions and

the information about each function is found in the manual.

1-2 Getting Started

MRC Prodigy Advance

2

Keys

Function

SYS + 0 Clear routes

SYS + 1 Set time

SYS + 2 Set time ratio

SYS + 3 Yard on/off

SYS + 4 Set time mode: AM/PM/military

SYS + 5 Set routes

SYS + 6 View your Cab address and set Cab address

SYS + 7 Set last Cab allowed to program locos on the Main Track

SYS + 8 Set last Cab allowed to program locos on the Program Track

SYS + 9 Set total number of operational Cabs