13. Pipe Insulation

OUTDOOR UNIT

mrcool.com | Page 17

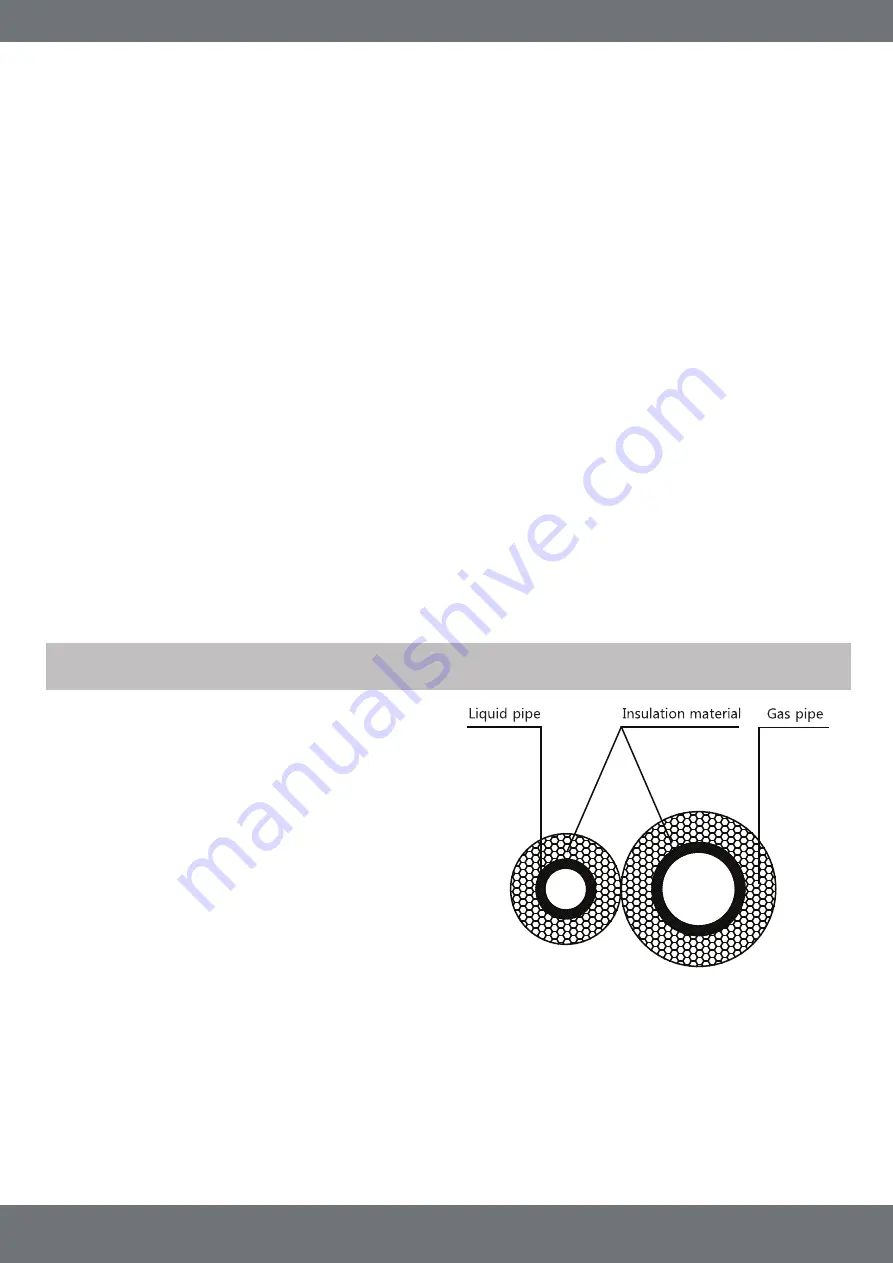

Insulation of refrigerant pipe

Operational procedure of refrigerant pipe insulation

1. Cut the suitable pipe

2. Insulation (except joint section)

3. Flare the pipe

4. Piping layout and connection

5. Vacuum drying

6. Insulate the joint parts

Purpose of refrigerant pipe insulation

• During operation, the temperature of gas pipe and liquid pipe could be extremely hot or cold. Therefore, it

is necessary to insulate them; otherwise it can affect the performance of the unit and damage the

compressor.

•

Gas pipe temperature is very low during cooling. If insulation is insufficient, condensation can form and cause

leakage.

• Temperature of gas pipe is very high, generally 122°F-212°F (50°C-100°C) during heating. Insulation must

be used to prevent injury.

Insulation material selection for refrigerant pipe

• Should be able to withstand temperatures of above 248°F (120°C)

• Insulation should be made of a material that meets the standards of local laws and regulations

• The thickness of insulation layer should be above 10 mm. If in a hot or wet environment, the layer of

insulation should be thicker.

Installation of insulation

NOTE

Gas pipe and liquid pipe should be insulated separately. If the gas pipe and liquid pipe are

insulated together, it will decrease the performance of air conditioner.

• The insulation material at the joint pipe should be

5-10 cm longer than the gap of the insulation

material.

• The insulation material at the pipe joint should be

inserted into the gap of the insulation material.

• The insulation material at the pipe joint should be

wrapped to the gas pipe and liquid pipe tightly.

• The linking part should use glue to paste together

• Be sure to not wrap the insulation material too

tightly, as it may force out air in the material and

cause the insulation to be less effective, and

lessen its durability.

Insulation of drainage pipe

Operational procedure of refrigerant pipe insulation

• Select the suitable pipe

• Insulation (except joint section)

• Piping layout and connection

• Drainage test

• Insulate the joint parts

Purpose of drainage pipe insulation

The temperature of condensate drainage water is very low. However, if insulation is insufficient, it could

cause condensate to form and cause leakage which could lead to property damage.

Fig. 13