Note

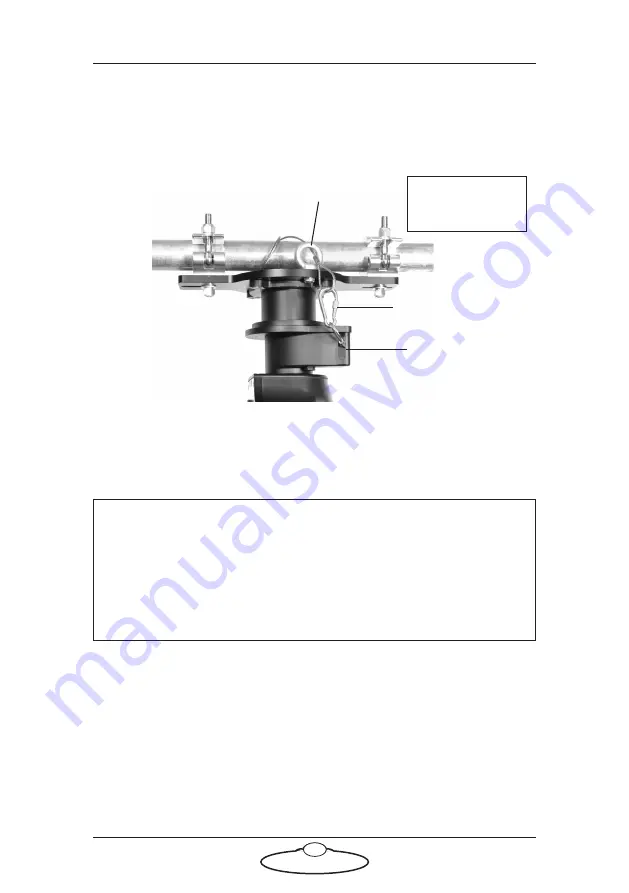

Safety cables should be wound up to keep them short:

PTA-1 Quick Start Guide

5

2.

Attach the safety cable around the bar, through at least one eyelet,

and through the pan safety hole (near the connector socket).

Remove any excess slack by making extra loops around the bar.

Then join with a carabiner and screw the carabiner shut.

In the event of a fall, the falling item has less opportunity

to get speed before the cable catches it.

This prevents them catching on any moving parts.

Pan safety hole

Eyelet

Wind any excess

cable around

scaffolding pole

Carabiner screwed shut

Summary of Contents for MRMC-2266-00

Page 4: ...PTA 1 Quick Start Guide iv...

Page 14: ...PTA 1 Quick Start Guide 10 Notes...

Page 16: ...PTA 1 Quick Start Guide 12 Notes...

Page 23: ...PTA 1 Quick Start Guide 19 Notes...

Page 26: ...PTA 1 Quick Start Guide 22...

Page 29: ...PTA 1 Quick Start Guide 25...

Page 30: ...PTA 1 Quick Start Guide 26...