Summary of Contents for ALTAIR 4XR

Page 1: ...MSAsafety com Operating Manual ALTAIR 4XR Multigas Detector Order No 10175896 00 ...

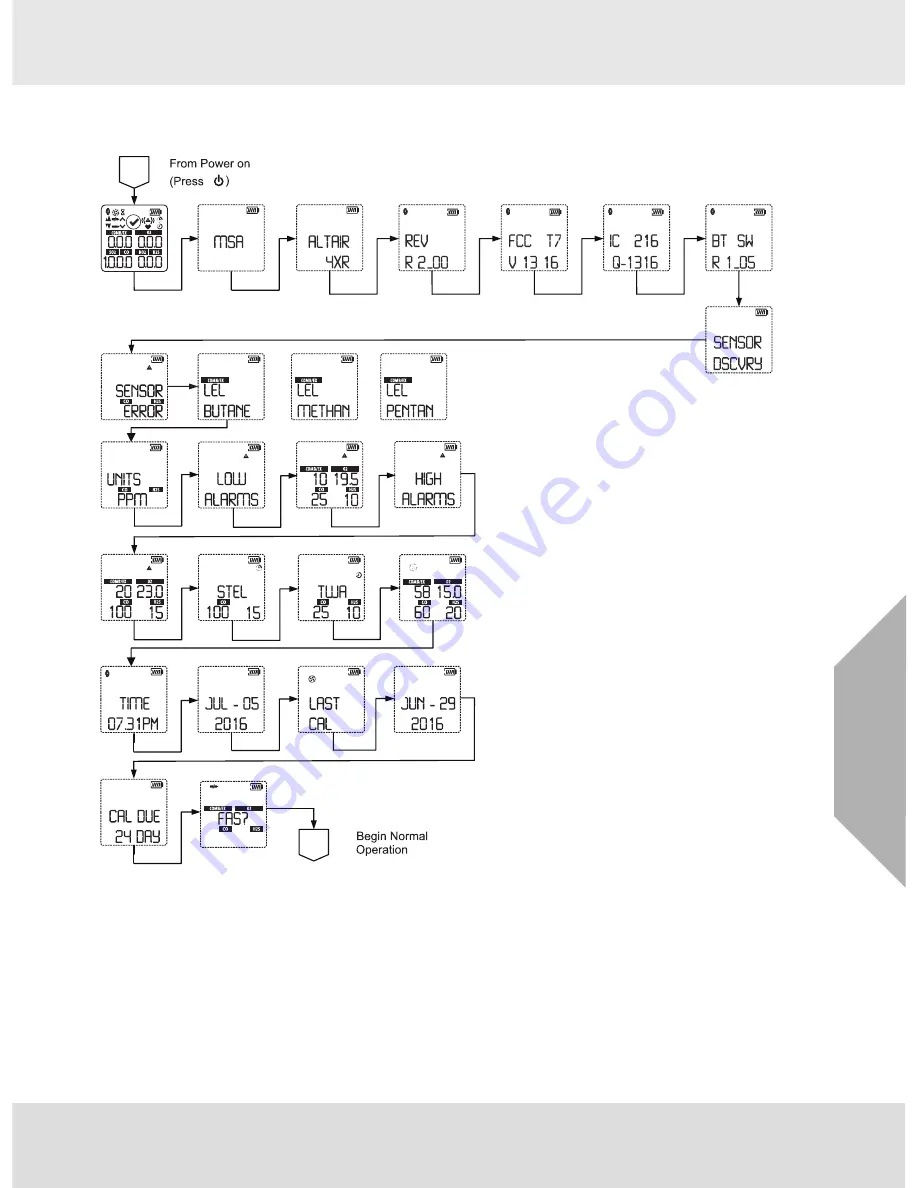

Page 52: ...ALTAIR 4XR 52 Appendix US 7 Appendix 7 1 Start Up Sequence Power on ...

Page 53: ...ALTAIR 4XR 53 Appendix US 7 2 Fresh Air Setup FAS ...

Page 55: ...ALTAIR 4XR 55 Appendix US ...

Page 56: ...ALTAIR 4XR 56 Appendix US 7 4 Bump Test ...

Page 57: ...ALTAIR 4XR 57 Appendix US 7 5 Options Setup ...

Page 58: ...ALTAIR 4XR 58 Appendix US 7 6 Sensor Setup ...

Page 59: ...ALTAIR 4XR 59 Appendix US 7 7 Calibrations ...

Page 60: ...ALTAIR 4XR 60 Appendix US ...

Page 61: ...ALTAIR 4XR 61 Appendix US 7 8 Alarm Setup ...

Page 62: ...ALTAIR 4XR 62 Appendix US 7 9 Time and Date Setup ...

Page 63: ...sales norrscope com ALTAIR 4XR 63 Appendix US 7 10 Bluetooth Setup ...