Power supply unit

PS-203-60

Page 11

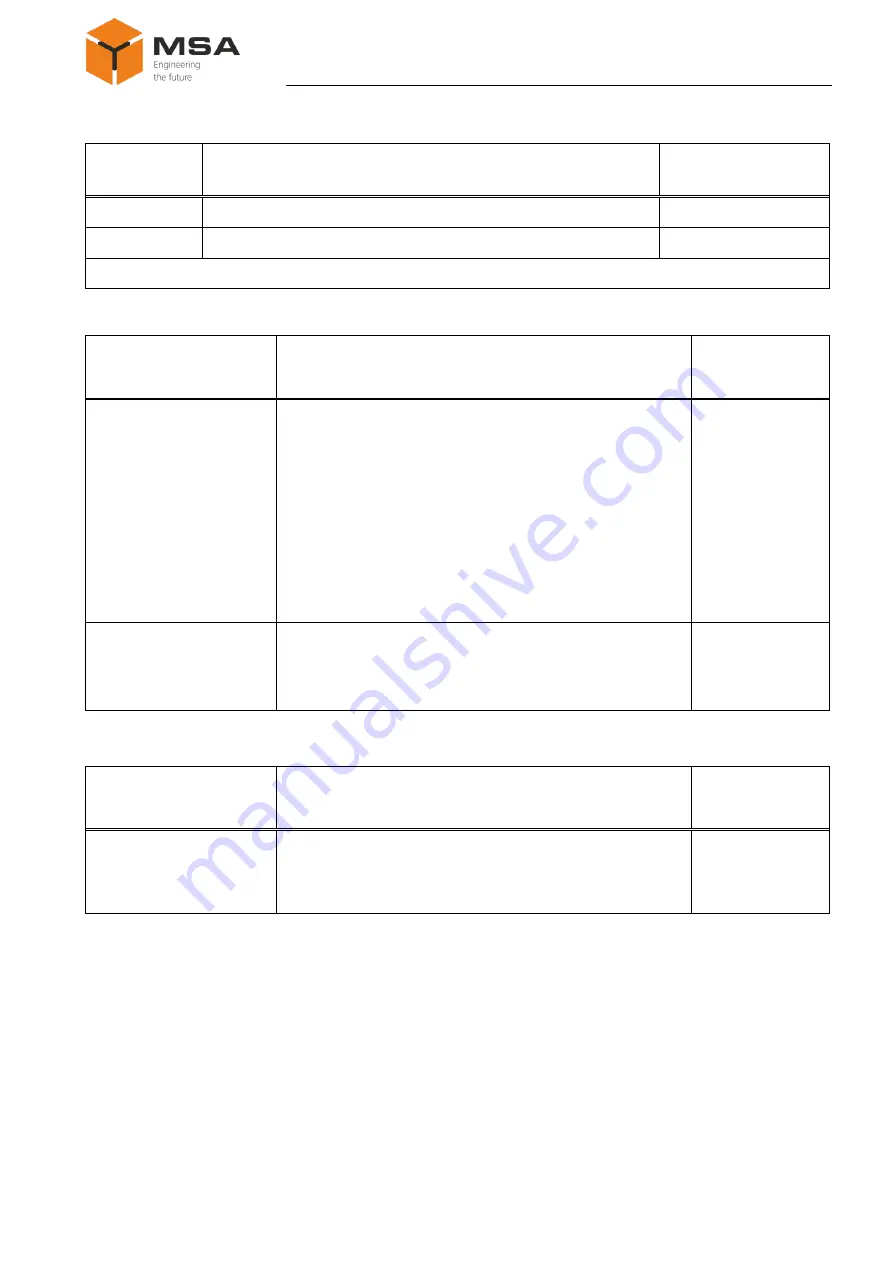

Table 5 – TS works

CL №

Name of work

TS

1

Visual check of the Product

+

2

Test of output voltage

+

Note – «+» – work is obligatory.

Table 6 – CL № 1. Visual check

To be done

Routine

Man-hours

per 1 Prod-

uct

Visually examine the Prod-

uct

1 Check completeness and appearance of the Product; me-

chanical damage, paint defects must be absent; marking

plates shall be present; legends shall be read easily

2 Clean up the Product surfaces with clean cloth

3 Remove severe contamination, parts of corrosion, oil

spots from the metal surfaces – using ethyl alcohol, avoid-

ing its penetration inside the Product; all surfaces clean dry

by clean cloth and dry up

4 If varnish paint coating is damaged, polish it with sand

paper, then clean with alcohol-soaked cloth, cover with

varnish and dry up

1 person

5 mins

Check reliability of cable

and bus connection to the

Product

1 Check that connectors and attaching screws are tight-

ened; provide further tightening if necessary

2 Check the cable intactness (no mechanical damage) with-

in visibility

1 person

5 mins

Table 7 – Check list №2. Test of output voltage

To be done

Routine

Man-hours

per 1 Prod-

uct

Test of output voltage

1 Switch on the Product power supply

2 Connect a voltmeter to output terminals of the Product

3 Supply power to the Product

4 Measure voltage on the output terminals

1 person

15 mins