7 Version 1.0

Operating Manual

1.4

M

EASUREMENT TOOLS

,

INSTRUMENTS AND APPLIANCES

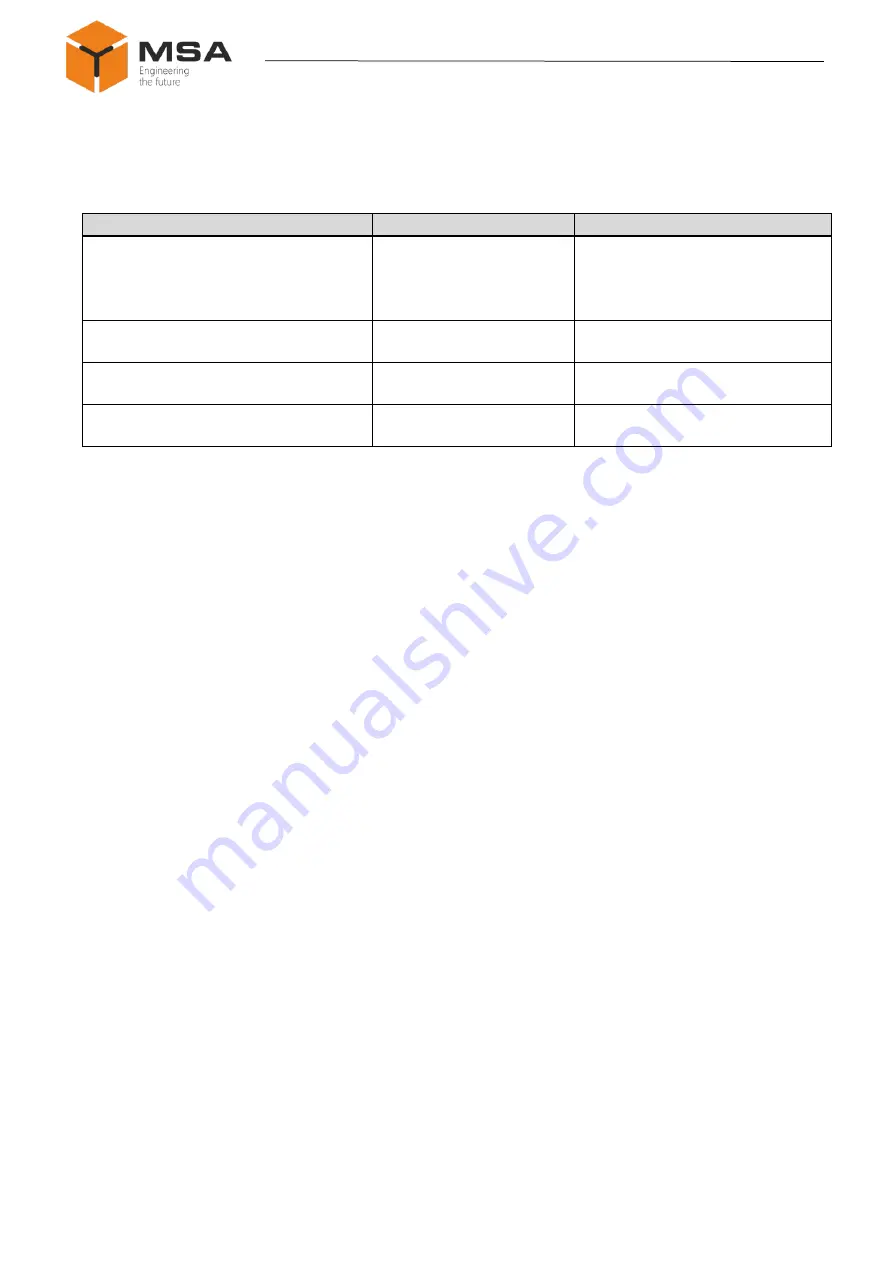

Table 3 describes tools and consumables required for the TS of the Product.

Table 3 – Number of consumables required for the TS

Name and identifier of consumables Weight of consumables

Note

Cleaning cloth

0.10 kg

1

To clean surfaces and parts of

the device – use clean cloth

2

To clean severe contamination

– use alcohol-soaked cloth

Rectified hydrolytic technical ethyl

alcohol

0.01 l

To soak cloth while removing

contamination

Varnish АК-113

0.05 kg

To cover surfaces of the device in

case of paint coating damage

Abrasive cloth

0.06 х 0.06 m

To polish surfaces of the device

in case of paint coating damage

1.5

M

ARKING AND SEALING

The Product has a nameplate

where a user can find a serial number, date of

manufacturing, weight, IP rating, rated input voltage and power consumption.

Sealing of the Product is not provided.

1.6

P

ACKAGING

When delivered, the Product is wrapped in stretch-film and placed in corrugated

cardboard box with foam plastic placed on each side, ensuring the Product transportation

and storage at warehouse.

Transport packaging is also used as a returnable packaging for transportation of

the Product to the place of repair and back.

Packaging sealing is not provided.