QM7500 Technical Manual

6 Servicing

QM31930/03093 Rev AD

Servicing

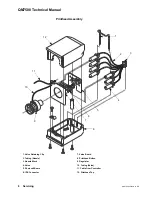

Preparing the QM7500 for Servicing

Before beginning work on the QM7500, follow these steps. Failure to follow these

steps may result in serious injury or damage to the unit.

To begin servicing the QM7500:

1) Remove the ink bottle.

2) Cover the front of the printhead with an absorbent cloth and purge the

printhead to remove any ink from the system.

3) Remove the QM7500 and power supply to a well-lit, static-free workbench.

Special Notes for Reassembling the QM7500 Printhead

Make sure the regulator is properly seated in the saddle of the printhead base to

allow proper connection of ink bottles. Also ensure that the valve retaining clip

offset is facing the valve board to prevent valves unseating from the valve board.

Finally, make sure that valves are properly oriented and seated in the valve board,

and that all wiring and tubing will not be kinked when the printhead cover is

replaced.