QM7500 Technical Manual

10 Servicing

QM31930/03093 Rev AD

Backflushing a Nozzle

1) Prepare the QM7500 for servicing. (See page 6.)

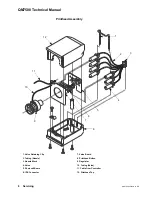

2) Remove the printhead cover by removing the three screws from the bottom of

the printhead. With the unit flat on the workbench, place your thumb on the

regulator and press down lightly as you lift up the top half of the printhead.

Note: Hold the components in place with your finger if necessary. Make

sure the valve/photocell board assembly remains in the printhead base.

Also, avoid unnecessary flexing of the cable between the two boards to

prevent damaging the cable connections.

3) From a print sample, locate the nozzle that needs backflushing.

4) Slide out the photocell board.

5) Disconnect the tubing connected between the valve and the nozzle from the

valve end only; allow it to hang free.

CAUTION: Remaining ink pressure may cause ink to shoot out of the

tubing.

6) Place a cloth at the open end of the tubing.

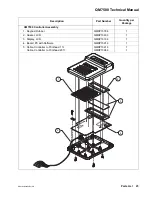

7) Install the cleaner assembly nozzle (from the service kit) on a bottle of solvent.

8) Press the solvent bottle against the clogged nozzle and spray solvent through it

for several seconds.

9) Reconnect the tubing to the valve.

10) Slide the photocell board back into place, photocells facing out.

11) Replace printhead cover, remount, and purge for several minutes.