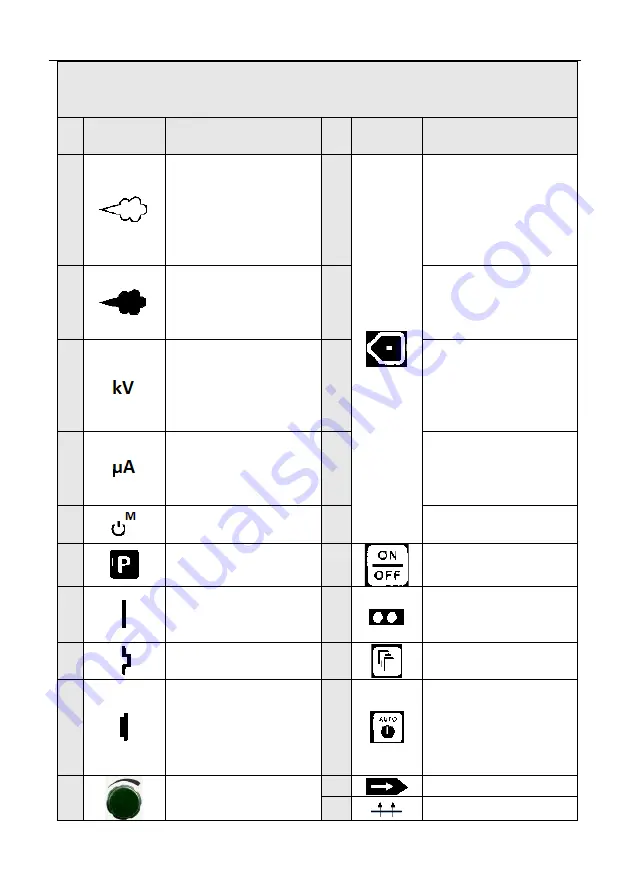

MASTER (I) / SLAVE (II) INTERFACE

SETTINGS (III)

DESCRIPTION

ICON/

KEY

FUNCTION

ICON/

KEY

FUNCTION

A

Dispensed air rate

K

Dispensed air control

(I); EPC gun auto

cleaning air key (II)

Atomiser valve

(injection pump)

calibration (III)

B

Dispensed powder rate

L

Dispensed powder

control (I); Dispensed

powder valve

calibration (III)

C

Unit voltage

M

Voltage control (I);

Electrode cleaning air

control (II); Internal

system comm number

(III)

D

Deposition current

N

Deposition current

control (I); Fluidising

air control (II); Master

mode selector key (III)

E

EPC activation icon

(auto or manual)

O

Program selector key

F

Coated substrate

mode selector (G, H I)

P

Power I/O switch

G

Straight coating mode

R

U

LED indicator: U –

Operating mode; R –

Power on

H

Complex coating mode

S

Master/slave

switchover selector

I

Duplex/recoating

mode

T

EPC auto fluidising

switch

J

Control dial

C

Electrode cleaning air

D

Fluidising air

Summary of Contents for MSW-PCSM-100-1

Page 31: ...ASSEMBLING THE CONTROL UNIT COMPONENTS INSTALLING THE REINFORCED HOSES LINES BACK PANEL ...

Page 49: ...MONTAŻ ELEMENTÓW JEDNOSTKI STERUJĄCEJ INSTALACJA WĘŻY ZBROJONYCH PRZEWODÓW PANEL TYLNI ...

Page 68: ...MONTÁŽ PRVKŮ ŘÍDICÍ JEDNOTKY INSTALACE HADIC VODIČŮ ZADNÍ PANEL ...

Page 76: ......

Page 144: ...VEZÉRLŐEGYSÉG ELEMEINEK ÖSSZESZERELÉSE MEGERŐSÍTETT TÖMLŐ VEZETÉK TELEPÍTÉSE HÁTSÓ PANEL ...

Page 152: ......

Page 162: ...MONTERING AF STYREENHEDENS KOMPONENTER MONTERING AF SLANGER LEDNINGER BAGPANEL ...

Page 170: ......