2

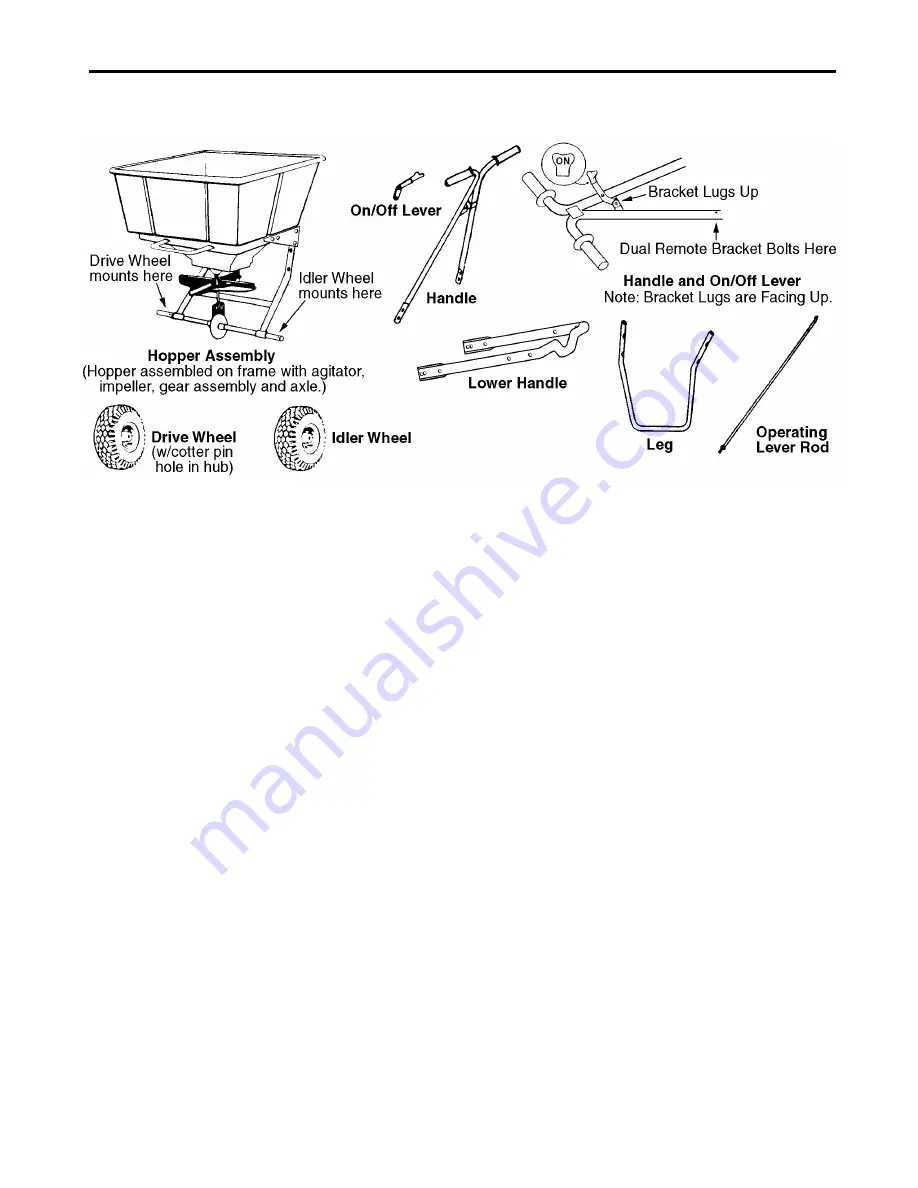

SECTION 1: ASSEMBLY INSTRUCTIONS

1.

Remove the spreader components from the

carton. You should find all of the parts shown

above plus the Hardware Package.

The Hardware Package contains:

2.

Place a spacer washer on each side of the axle

next to the axle bushing. Mount the drive wheel on

the side of the axle with the predrilled hole near

the axle bushing as shown in the illustration.

Attach by fastening on the inside of the wheel with

the 3/16 x1-3/4 cotter pin.

3.

Mount the idler wheel on the other side of the axle.

Add a spacer washer and put the 3/16 x 1-1/4

cotter pin through the axle on the outside of the

wheel and spacer washer.

4.

Mount the leg to the hopper assembly by fastening

with four 1/4-20 x 2-1/4 hex head cap screws and

four 1/4-20 locknuts. Use eight 1/4 flat washers

under the heads of the cap screws and under the

locknuts.

5.

Mount the lower handle to the hopper assembly by

fastening with four 1/4-20 x 5/8 Phillips head

machine screws and four 1/4-20 locknuts.

6.

Attach the handle (with the on/off bracket lugs

facing up) to the lower handle using four 1/4-20 x

1-1/2 Phillips head machine screws and four 1/4-

20 locknuts. Use eight 1/4 flat washers under the

heads of the machine screws and under the

locknuts.

7.

Fasten the on/off lever to the handle's bracket lugs

using the clevis pin in the bottom hole of the lever.

Insert the clevis pin from left to right, facing the

rear of the hopper. Lock with the 3/32 x 1/2 cotter

pin.

8.

Attach the operating lever rod assembly to the

lever rod adjusting bracket at the bottom-rear of

the hopper. First insert clevis pin through hole in

lever rod adjusting bracket, than place flat washer

on to clevis pin. Insert clevis pin through top hole

in bellcrank pivot and secure with flat washer and

cotter pin.

9.

Attach the operating lever rod to the on/off lever

by inserting the bent end of the rod into the top

hole of the lever from left to right and install the C-

clip. Pull the on/off lever to the off position and set

the main slide plate to the fully closed position by

adjusting the 5/16 hex nuts on the bottom of the

operating lever rod.

10. Attach the dual remote bracket to the lower right

side of the handle using a 1/4-20 x 1-1/2 Phillips

head machine screw and a 1/4-20 locknut.

11. Insert the screen into the hopper.

1

Cotter Pin, 3/16 x 1-3/4

1

Cotter Pin, 3/16 x 1-1/4

3

Spacer Washers, 3/4 I.D.

4

Cap Screws, 1/4-20 x 2-1/4, Hex Head

4

Machine Screws, 1/4-20 x 5/8, Phillips Head

5

Machine Screws, 1/4-20 x 1-1/2, Phillips Head

16

Flat Washers, 1/4

13

Hex Nuts, 1/4-20, Nylock

2

Clevis Pin, 1/4 x 1/2

2

Cotter Pin, 3/32 x 1/2

2

Cable Ties

1

C-Clip