Maintenance Schedule

First 5 Hours

Each Use or

Every 5 Hrs.

Every Season

or 25 Hours

Every Season

or 50 Hours

Every Season

or 100 Hours

Service Dates

Check Engine Oil Level

P

Change Engine Oil

P

P

Check Air Cleaner

(If equipped)

P

Service Air Cleaner

(If equipped)

P

Check Spark Plug

P

Replace Spark Plug

P

Clean Engine Shroud

(If equipped)

P

Clean around muffler

P

Replace Fuel Filter

(If equipped)

P

Periodic inspection and adjustment of the engine is essential if

high level performance is to be maintained. Regular maintenance

will also ensure a long service life. The required service intervals

and the kind of maintenance to be performed are described

in the table above. Follow the hourly or calendar intervals,

whichever occur first. More frequent service is required when

operating in adverse conditions.

WARNING!

Shut off the engine before performing

any maintenance. To prevent accidental start-up,

disconnect the spark plug boot.

NOTE:

If engine must be tipped to transport equipment or to

inspect or remove grass, keep spark plug side of engine up.

Transporting or tipping engine spark plug down may cause

smoking, hard starting, spark plug fouling, or oil saturation of air

cleaner.

WARNING!

If the engine has been running, the

muffler will be very hot. Be careful not to touch the

muffler.

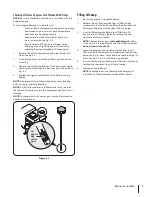

Checking and Changing the Oil

To avoid engine damage, it is important to:

•

Check oil level before each use and every 5 operating hours

when the engine is warm.

•

Change the oil after the first 5 operating hours and every

50 operating hours thereafter. Engine should still be warm

but NOT hot from recent use.

Oil Fill Cap and Dipstick

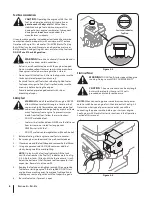

WARNING!

Before tipping engine or equipment to

drain oil, drain fuel from tank by running engine

until fuel tank is empty.

1.

Carefully disconnect the spark plug wire and keep it away

from the spark plug. Refer to Fig. 6-1 for spark plug location.

Spark Plug

Spark Plug

Boot

Figure 6-1

Maintenance

6

13

Summary of Contents for 165-SUC

Page 24: ...Notes 21...