16

s

ectiOn

7— s

ervice

Shredder Blade

Stop the engine and make certain that all moving parts

1.

have come to a complete stop.

Disconnect the spark plug wire and ground against the

2.

engine.

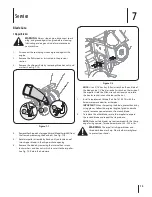

Lower the hopper assembly and block up the housing.

3.

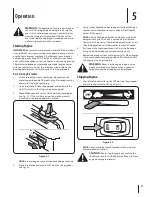

Remove the six hex lock nuts and flat washers from the

4.

weld studs on the flail housing. See Fig. 7-3A. Retain the

hardware.

Carefully separate the hopper assembly from the impeller

5.

assembly and remove the support plate. See Fig. 7-3B.

NOTE:

When reassembling the support plate, make certain

the embossed tab faces inward towards the impeller.

Remove the two wing knobs and cupped washers that

6.

secure the chute deflector and raise the chute.

Insert a 1/2” or 3/4” diameter pipe through the flail screen

7.

into the impeller to keep it from turning or remove the flail

screen and insert a piece of wood into the chute opening.

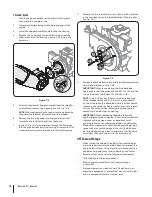

Remove the two internal hex screws, lock washers, and hex

8.

lock nuts which secure the shredder blade to the impeller.

See Fig. 7-4A.

Remove the hex bolt, lock washer, and flat washer to completely

9.

free shredder blade. See Fig. 7-4B.

IMPORTANT:

When reassembling the shredder blade,

tighten center bolt to between 550 and 700 in.-lbs. and the

two outside bolts to between 250 and 350 in.-lbs.

NOTE:

Use a 3/16” hex key (Allen) wrench on the outside

of the shredder blade and a 1/2” box (or socket) wrench

on the inside of the shredder blade. Hold the Allen wrench

stationary and rotate the box (or socket) wrench to loosen

the nut. Use caution when removing the blade to avoid

contacting the weld studs on housing.

IMPORTANT:

When sharpening the blade, follow the

original angle of grind as a guide. It is extremely important

that each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An unbalanced

blade will cause excessive vibration when rotating at high

speeds and may cause damage to the unit. The blade can

be tested by balancing it on a screwdriver or nail. Remove

metal from the heavy side until it is balanced evenly.

Off-Season Storage

When storing the chipper shredder in an unventilated or

•

metal storage shed, care should be taken to rustproof the

non-painted surfaces. Using a light oil or silicone, coat the

equipment, especially any springs, bearings, and cables.

Remove all dirt from exterior of engine and equipment.

•

Follow lubrication recommendations.

•

Refer to engine manual for correct engine storage

•

instructions.

Store equipment in a clean, dry area. Do not store in an

•

area where equipment is present that may use a pilot light

or has a component that can create a spark.

Figure 7-3

Figure 7-4

A

B

B

A

A

Summary of Contents for 24A-45M3000

Page 19: ...Notes 10 19...