12

Before lubricating,

repairing, or

inspecting, disengage

all controls and stop

engine. Wait until all

moving parts have

come to a complete

stop. Disconnect the

spark plug wire and

ground it against the

engine to prevent

unintended starting.

WARNING

6

Maintenance

& Service

General Recommendations

1. Always observe safety rules when performing any

maintenance.

2. The warranty on this snow thrower does not cover

items that have been subjected to operator abuse or

negligence. To receive full value from the war-

ranty, operator must maintain the snow thrower as

instructed in this manual.

3. Periodically check all fasteners and hardware to

make sure these are tight.

WARNING: Before servicing, repairing,

lubricating or inspecting, disengage all

controls and stop engine. Wait until all

moving parts have come to a complete

stop. Disconnect spark plug wire and

ground it against the engine to prevent

unintended starting. Always wear safety

glasses during operation or while per-

forming any adjustments or repairs.

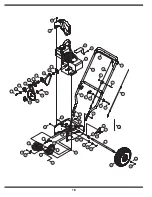

Replacing the Shave Plate

and Skid Shoes

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. These should be

checked periodically and replaced when necessary

1. To replace, remove two carriage bolts and hex nuts

securing each skid shoe to the auger housing. See Fig. 9

2. Reassemble new skid shoes with hardware just removed.

Make sure the skid shoes are adjusted to be level.

3.

To remove shave plate:

Remove both skid shoes

and hardware including carriage bolts, and hex

nuts which attach shave plate to the snow thrower

housing. For location of shave plate, see Figure 9.

4. Reassemble new shave plate, making sure heads

of the carriage bolts are to the inside of the housing.

Reinstall skid shoes. Tighten securely.

Servicing Augers

The augers are secured to the spiral shaft with four

shear pins and cotter pins. If you hit a foreign object or

ice jam, the snow thrower is designed so that the pins

may shear. Refer to Figure 9.

If the augers do not turn, check if the pins have sheared.

Replace, if needed, with proper shear pins. Refer to

item 42 on page 17 for part number.

IMPORTANT:

NEVER replace the auger shear pins with

standard pins or fasteners. Any damage to the auger

gearbox or other components, as a result of doing so,

will NOT be covered by your snow thrower’s warranty.

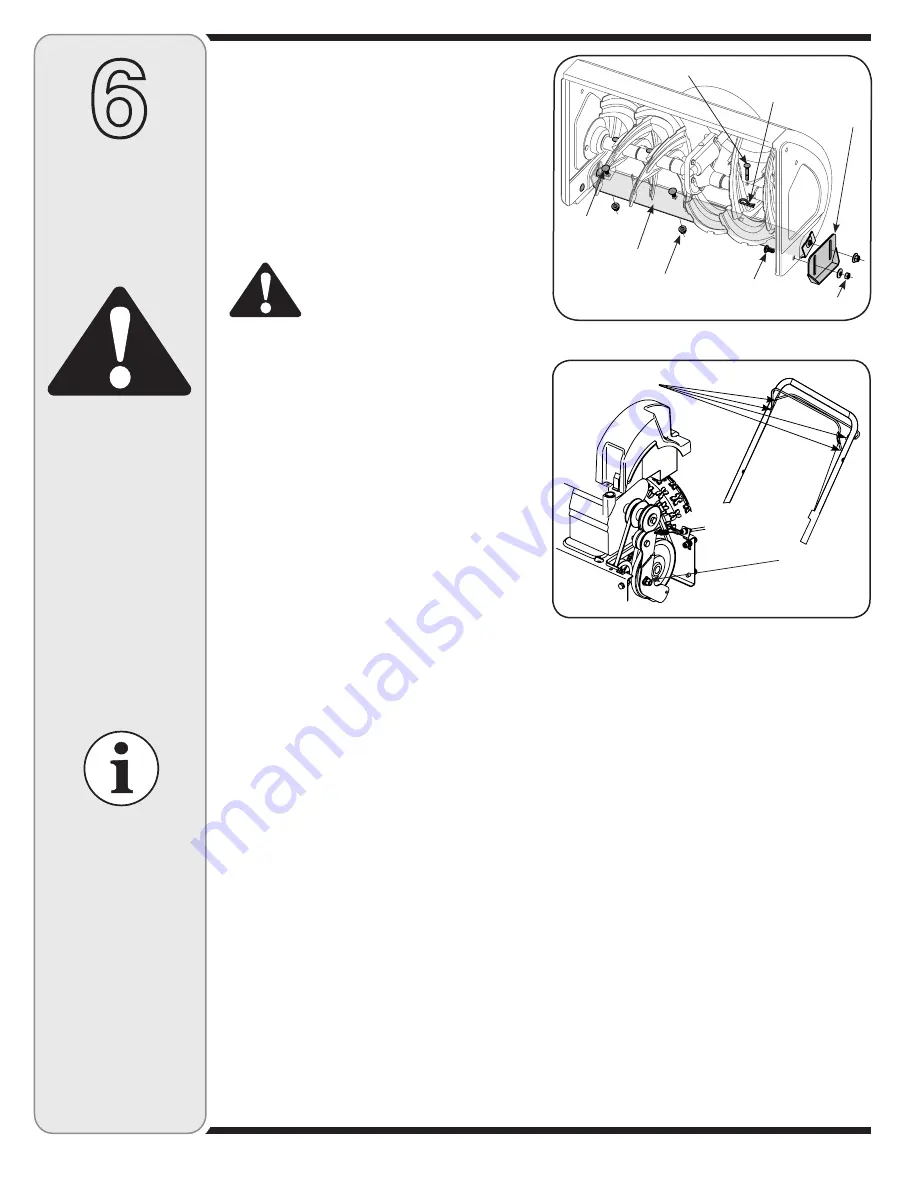

Lubrication

For a view of the lubrication points on the snow thrower,

see Figure 10.

1. Lubricate pivot points on the auger control and drive

control with a light engine oil once a season.

2. Lubricate the auger idler bracket with a light engine oil

once a season.

Engine

Listed below are general recommendations about

maintaining your snow thrower engine. For further details,

refer to the accompanying engine manual.

1. Before operating snow thrower, check the oil level.

2. Change engine oil after first two hours of operation

and every 25 hours thereafter.

3. Clean spark plug and reset the electrode gap to

0.030” at least once a season or every 100 hours of

operation; replace every 200 hours of operation.

Check V-Belts

Follow instructions below to check condition of drive belts

every 50 hours of operation.

1. Remove the plastic belt cover on the front of the engine

by removing the self-tapping screw and pressing the

plastic tabs to release the belt cover. See Figure 11

2. Visually inspect for frayed, cracked, or excessively

worn out belts. Replace, if necessary, following

instructions on page 13.

Figure 10

NOTE:

If auger continues to

rotate with the control

disengaged, shut off

engine and re-adjust.

Lubricate

Lubricate

Figure 9

Shear Pin

Cotter Pin

Carriage

Bolt

Shave Plate

Hex Nut

Skid Shoe

Carriage

Bolt

Hex Nut