1

9

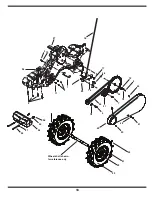

Illustrated

Parts List

Model 450

Series

To order replacement

parts, contact

1 (800) 800-7310

or visit

www.mtdproducts.com

Ref.

Part No.

Part Description

1.

747-1152

Shift Rod

2.

649-0041

Upper Handle Ass’y

3.

649-0034

Lower Handle Ass’y

4.

710-3005

Hex Screw 3/8-16 x 1.25

5.

710-3056

Hex Screw 5/16-18 x 3.25

6.

711-0415

Clevis Pin 3/8-1.62

7.

712-0379

Flange Lock Nut 3/8-24

8.

712-0429

Hex Lock Nut 5/16-18

9.

714-0147

Cotter Pin

10.

720-0313

Grip

11.

720-0210A

T-Knob

12.

720-0278A

Foam Grip

14.

726-0317

Cable Tie

15.

735-0246

Plug

16.

736-0117

Flat Washer 3/8 ID x .620 OD

17.

736-0242

Bell Washer .340 ID x .872 OD

18.

738-0958

Shoulder Spacer

19.

784-0190

Handle Adjustment Crank

20.

784-0191

Hex Nut Retainer Bracket

21.

786-0120

Depth Stake

22.

747-1219

Bail Clutch

23.

786-0181

Shift Lever Rod

24.

686-0044A

Tine Shield Cover Ass’y

25.

710-0176

Hex Cap Screw 5/16-18 x 2.75

26.

710-3008

Hex Cap Screw 5/16-18 x .750

27.

710-3097

Carriage Bolt 3/8-16 x 1.0

28.

712-0421

Wing Nut

29.

736-0169

Lock Washer 3/8

30.

712-04063

Flange Nut 5/16-18

31.

726-0106

Cap Nut

32.

738-0849

Hex Screw 5/16-18 x .75”

33.

747-0432

Rod

34.

750-0885A

Spacer .322 x .625 x 2.0

Ref.

Part No.

Part Description

35.

786-0090

Shoulder

36.

786-0113

Tine Shield Hinge Flap

37.

786-0176

RH Handle Bracket

38.

786-0177

LH Handle Bracket

39.

786-0178

Tine Shield

40.

786-0179

Tine Shield Bracket

41.

786-0180

Shoulder Spacer Bracket

42.

686-0109

Shift Crank Ass’y

44.

710-1017

Screw 1/4-14 x .625

46.

715-0120

Spiral Pin 3/16 x 1.0

49.

784-0208C

Shift Cover

50.

711-0415

Clevis Pin

51.

712-3054

Hex Nut 3/8-24

53.

742-0305

13” Articulating Tine

54.

738-0689

Shoulder Bolt

55.

736-0208

Flat Washer .51” ID x 1.50” OD

56.

736-0253

Bell Washer .515” ID x 1.14” OD

57.

738-0688

Shoulder Bolt

58.

784-0160

Tine Adapter Ass’y 18”

59.

714-0149B

Internal Cotter Pin

60.

735-0127

Rubber Washer

61.

714-0104

Cotter Pin

62.

710-3022

Hex Screw 3/8-16 x 2.75”

63.

736-0204

Flat Washer

64.

712-04065

Flange Nut 3/8-16

65.

736-0169

Lock Washer

66.

712-3017

Hex Nut 3/8-16

67.

710-0946

Truss Screw 1/4-20 x .65

68.

712-0324

Hex Lock Nut 1/4-20

69.

726-0273

Battery Hose Clamp 5/16

70.

736-3090

Flat Washer .260 ID x .720 OD

71.

784-0161

Tine Adapter Plate

NOTE:

Specifications are

subject to change without

notification or obligation.

Images my not reflect your

exact model and are for

reference purposes only.