9

To Stop Engine

•

To stop engine, remove the ignition key. Do not

turn key. Disconnect the spark plug wire from the

spark plug to prevent accidental starting while

equipment is unattended.

To prevent starter freeze-up:

•

Run engine for a few minutes before stopping to

help dry off any moisture on the engine.

•

Electric Starter:

Connect power cord to switch

box on engine, then to 120 volt AC receptacle.

With the engine running, push starter button and

spin the starter for several seconds. The unusual

sound made by spinning the starter will not harm

engine or starter. Disconnect the power cord from

receptacle first, and then from switch box.

•

Recoil Starter:

With engine running, pull starter

rope with a rapid, continuous full arm stroke three

or four times. Pulling the starter rope will produce a

loud clattering sound, which is not harmful to the

engine or starter.

•

Wipe all snow and moisture from the carburetor

cover in the area of the control levers. Also, move

control levers back and forth several times. Leave

throttle control lever in the STOP or OFF position.

Leave choke control in the FULL choke position.

•

Remove ignition key and disconnect spark plug

wire. Do not turn key.

IMPORTANT:

Do not lose ignition key. Keep it in a safe

place. Engine will not start without the ignition key.

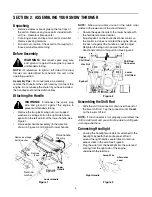

To Engage Drive

•

With the engine running near top speed, move

shift lever into one of the five FORWARD positions

or two REVERSE positions. Select a speed

appropriate for the snow conditions that exist. Use

the slower speeds until you are familiar with the

operation of the snow thrower.

•

Squeeze the auger control and the augers will

turn. Release it and the augers will stop.

•

Squeeze traction control and the snow thrower will

move. Release it and unit will stop. Never move

shift lever without releasing traction control.

To Engage Augers

•

To engage augers and start throwing snow,

squeeze the auger control against the left handle.

Release to stop the augers.

Tire Chains

(Optional Equipment)

•

Tire chains should be used whenever extra

traction is needed. If your unit is not equipped with

tire chains, you may purchase them.

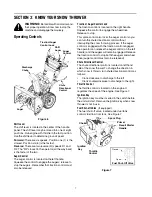

Operating Tips

NOTE:

Allow the engine to warm up for a few minutes

as the engine will not develop full power until it reaches

operating temperature.

WARNING:

The muffler, engine and their

surrounding areas become hot and can

cause a burn. Do not touch.

•

Discharge snow downwind whenever possible.

Slightly overlap each previous path.

•

Set the skid shoes 1/4" below the scraper bar for

normal usage. The skid shoes may be adjusted

upward for hard-packed snow. Adjust downward

when using on gravel or crushed rock.

•

Avoid possible starter freeze-up. Clean the snow

thrower thoroughly after each use.

SECTION 5: MAKING ADJUSTMENTS

WARNING:

NEVER attempt to make any

adjustments while the engine is running,

except where specified in the operator’s

manual.

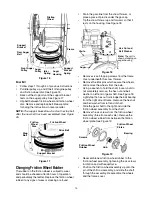

Chute Assembly

The distance snow is thrown can be adjusted by

changing the angle of the chute assembly. Refer to

Chute Tilt Control on page 7.

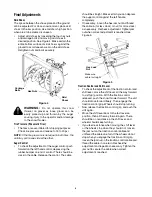

Skid Shoe

The space between shave plate and ground can be

adjusted by raising or lowering the skid shoes. Refer to

Skid Shoe Adjustment on page 12.

Traction Control

Refer to Final Adjustments on page 6 to adjust traction

control. If you are want to check further for correct

adjustment, proceed as follows:

WARNING:

Drain the gasoline out of snow

thrower engine, place a piece of plastic film

under the gas cap to avoid spillage before

beginning the job.

•

Tip the snow thrower forward, allowing it to rest on

the auger housing.

•

Remove the frame cover underneath the snow

thrower by removing six self-tapping screws.

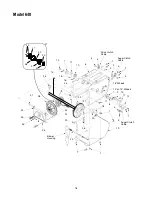

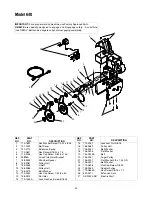

Summary of Contents for 640

Page 22: ...22 YOUR NOTES Date Comment ...

Page 23: ...23 YOUR NOTES Date Comment ...