27

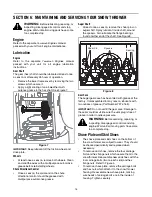

Styles C & D

Wheel Assembly

Complete

Wheel Size

Rim Only

Tire Only

Air Valve

634-04144

13 x 4

634-04151

734-1732

734-0255

634-04143

13 x 5

634-04151

734-1527

734-0255

634-04142

15 x 5

634-04151

734-1859

734-0255

634-04141

16 x 4.8

634-04140

734-1530

734-0255

NOTE:

Snow thrower features and components vary by model. NOT all parts listed above and pictured on the previous page

are standard equipment.

REF.

NO.

PART

NO.

DESCRIPTION

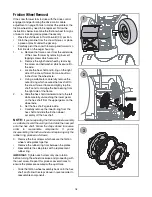

1

617-04026

Gear Assembly, 16/44T

2

617-04025

Gear Assembly, 16/44T

3

656-0012A

Disc Assembly, Friction Wheel, .375

4

684-04066

Wheel Assembly, Friction, 4.9 OD

5

684-04045

Support Bracket Ass’y, Friction Wheel

6

684-04139

Shift Assembly, Rod

7

710-0627

Screw, 5/16-24 x .750, Gr5

8

710-0788

Screw, 1/4-20 x 1.000

9

710-1652

Screw, 1/4-20 x .625

10

711-04246A

Hex Shaft, Drive, .75

11

712-0711

Nut, Jam, 3/8-24, Gr2

12

714-0161

Key, Hi-pro 3/16 x 5/8

13

716-0231

Ring, E Type, .750

14

716-0136

Ring, E-Type, .875

15

717-04129A

Pinion, 16T

16

717-04137A

Gear, 44T

17

790-00082

Idler, Bracket, Drive

18

726-0221

Nut, Speed, .500

19

732-0264

Extension Spring

20

736-0242

Washer, Bell, .340 x .872 x .060

21

736-04161

Washer, Flat, .75 x 1.00 x .060

22

736-0300

Washer, Flat, .406 x .875 x .059

23

736-0105

Washer, Bell, .375 x .870 x .063

24

736-0287

Washer, Flat, .793 x 1.24 x .060

25

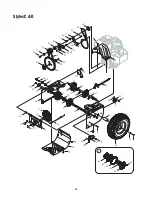

See Chart

Wheel Assembly, Complete

26

731-04873

Spacer, 1.25 OD x .75 ID x 3.00

731-04877*

Spacer, 1.25 OD x .75 ID x 1.50

27

738-04095A

Axle, .75 x 22

28

738-0924

Screw, 1/4-28 x .375

29

741-0563

Bearing, Ball, 17 x 40 x 12

30

741-0245

Bearing, Hex Flange x .75 ID

31

746-0897

Cable, Auger, 44.75

32

746-04086

Cable, Drive, 41.75

* Found on models with a 22-inch auger housing only.

33

748-0190

Spacer, .508 ID x .75 OD x .68

34

756-0625

Roller, Cable

35

784-5687A

Guide Bracket, Auger Cable

36

790-00072

Frame

37

790-00096

Guide Bracket, Front, Auger Cable

38

790-00054

Cover, Frame

39

790-00055

Roller Bracket, Drive Cable

40

710-0191

Screw, 3/8-24 x 1.25, Gr8

41

710-0597

Screw, 1/4-20 x 1.00, Gr5

42

710-0654A

Screw, Sems, 3/8-16 x 1.00

43

710-1245B

Screw, 5/16-24 x .875, Gr8

44

712-04064

Nut, Flange Lock, Nylon, 1/4-20, GrF

45

731-04792

Cover, Belt

46

732-0710

Spring, Extension, .38 OD x 2.68

47

736-0247

Washer, Flat, .406 x 1.25 x.157

48

736-0505

Washer, Flat, .34 x 1.50 x .150

49

741-0919

Bearing, Ball, 20 x 47 x 14

50

748-0234

Shoulder Spacer

51

748-04053

Pulley, Adapter, .75 Dia.

52

750-04230

Spacer, .777 OD x .260 ID x.550

53

750-04303

Spacer, .875 ID x 1.185 OD

54

754-04050

V-Belt, 1/2”

55

754-0456

V-Belt, 3/8”

56

756-04109

Pulley, Auger, 8.1 x .50

57

756-04113

Pulley, Half, 2.600 OD

58

756-04114

Pulley, Half, 2.2 OD

59

790-00062

Washer, Bearing, 2.12 OD x .255 ID

60

790-00010

Plate, Friction, 12 Pt 4.60 Dia

61

790-00011

Plate, Friction, Extrs, 12 Pt 4.60 Dia

62

710-0896

Screw, Self-tapping, 1/4-14 x 0.625

63

618-04169

Bearing Assembly, Friction Wheel

64

718-04070

Hub, Friction Wheel

65

735-0243B

Friction Wheel Rubber, 4.875 OD

REF.

NO.

PART

NO.

DESCRIPTION

Summary of Contents for 737-0168

Page 21: ...21 NOTES ...