16

S

ection

4 — P

roduct

c

are

5.

Remove the oil drain plug and drain the oil

into a suitable container with a capacity of

no less than 64 oz.

6.

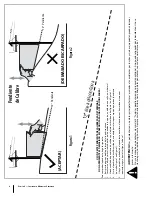

Tip the riding mower slightly in the

direction of the suitable container to aid in

fully draining all of the oil from the engine.

WARNING

Before tipping engine or equipment to drain oil, drain fuel

from tank by running engine until fuel tank is empty.

7.

Replace the oil drain plug and tighten. Be

careful not to overtighten the oil drain plug.

8.

Refill the engine with new oil as instructed

in the Engine Operator’s Manual packed

with your riding mower.

Note: Refer to the Engine Operator’s

Manual packed with your riding mower for

information regarding the quantity and

proper viscosity of motor oil.

Lubrication

WARNING

Before lubricating, repairing, or inspecting, always disengage

PTO, move shift lever into neutral position, set parking brake,

stop engine and remove key to prevent unintended starting.

Engine

Lubricate the engine with motor oil as instructed

in the Engine Operator’s Manual packed with your

riding mower.

Pivot Points & Linkage

Lubricate all the pivot points on the drive system,

parking brake and lift linkage at least once a

season with light oil.

Rear Wheels

The rear wheels should be removed from the axles

once a season. Lubricate the axles and the rims well

with an all-purpose grease before re-installing them.

Front Axles

Each end of the riding mower’s front pivot bar may be

equipped with a grease fitting. Lubricate with a grease

gun after every 25 hours of riding mower operation.

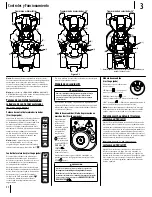

Steering Rack & Pinion

Once per season, or every 25 hours of operation,

it will be necessary to lubricate the steering rack

and pinion gear (a) located under the front of the

riding mower. Using standard automotive grease,

apply grease to the front side and rear side of the

steering rack and pinion gear (a), as indicated in

Figure 4-2.

(a)

Figure 4-2

Cleaning the Tractor

If the engine has been running, allow it to cool for

at least half an hour before cleaning. Periodically

remove dirt build-up from engine. Clean cooling fins

every 25 hours. Clean with a brush or compressed air.

Important: Do not spray engine with water to clean

because water could contaminate fuel. Using a

garden hose or pressure washing equipment can also

force water into the air cleaner or muffler opening.

Water in the air cleaner will soak the paper element,

and water that passes through the element or

muffler can enter the cylinder, causing damage.

Any fuel or oil spilled on the machine should

be wiped off promptly. Do NOT allow debris to

accumulate around the cooling fins of the engine

or on any other part of the machine.

Important: The use of a pressure washer to clean

your riding mower is NOT recommended. It may

cause damage to electrical components, spindles,

pulleys, bearings or the engine.

WARNING

Accumulation of debris around muffler could cause a fire.

Inspect and clean before every use.

Muffler

WARNING

Temperature of muffler and nearby engine areas may exceed

150˚F (65˚C). Avoid contact with these areas.

Inspect muffler periodically, and replace if necessary.

Replacement parts for the muffler must be the same

and installed in the same position as the original parts.

Battery

Clean the battery by removing it from the riding

mower and washing with a baking soda and

water solution. If necessary, scrape the battery

terminals with a wire brush to remove deposits.

Coat terminals and exposed wiring with grease or

petroleum jelly to prevent corrosion.

The battery is sealed and is maintenance-free. Acid

levels cannot be checked.

•

Always keep the battery cables and terminals

clean and free of corrosive build-up.

•

After cleaning the battery and terminals,

apply a light coat of petroleum jelly or grease

to both terminals.

•

Always keep the rubber boot positioned over

the positive terminal to prevent shorting.

Important: If removing the battery for any

reason, disconnect the NEGATIVE (Black)

wire from it’s terminal first, followed by

the POSITIVE (Red) wire. When re-installing

the battery, always connect the POSITIVE

(Red) wire its terminal first, followed by

the NEGATIVE (Black) wire. Be certain that

the wires are connected to the correct

terminals; reversing them could change

the polarity and result in damage to your

engine’s alternating system.

Deck Wash System (If equipped)

Your riding mower’s deck is equipped with a water

port on its surface as part of its deck wash system.

Use the deck wash system to rinse grass clippings

from the deck’s underside and prevent the buildup

of corrosive chemicals. Complete the following

steps AFTER EACH MOWING:

1.

Drive the riding mower to a level, clear spot

on your lawn, near enough for your garden

hose to reach.

CAUTION

Make certain the riding mower’s discharge chute is directed

AWAY from your house, garage, parked cars, etc.

2.

Disengage the PTO (Blade Engage), set the

parking brake and stop the engine.

3.

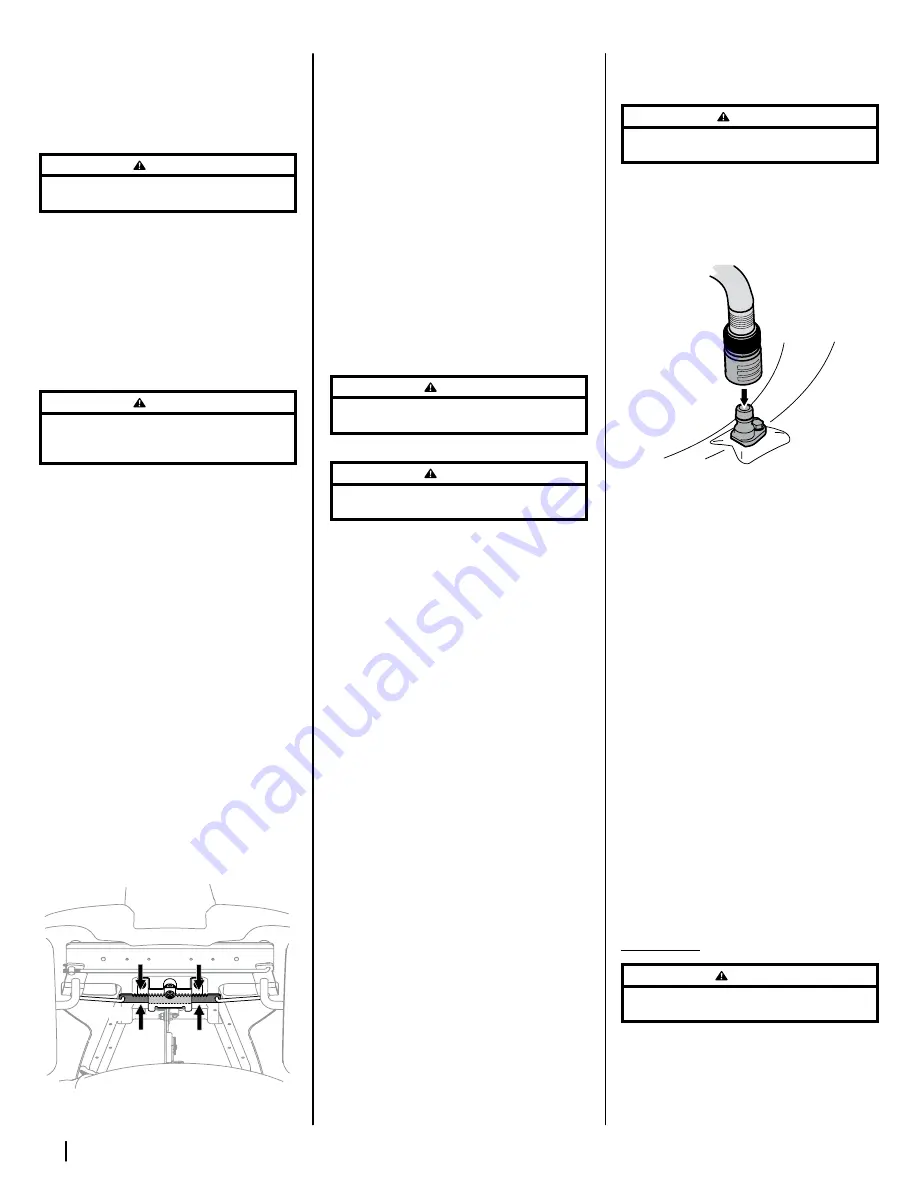

Thread the hose coupler (a) (packaged with

the Operator’s Manual) onto the end of your

garden hose (b). See Figure 4-3.

(c)

(a)

(b)

Figure 4-3

4.

Attach the hose coupler (a) to the water port (b)

on your deck’s surface. See Figure 4-3.

5.

Turn the water ON.

6.

While sitting in the operator’s position on

the riding mower, start the engine and

place the throttle lever in the FAST (rabbit)

position.

7.

Move the riding mower’s PTO into the ON

position.

8.

Remain in the operator’s position with the

cutting deck engaged for a minimum of

two minutes, allowing the underside of the

cutting deck to thoroughly rinse.

9.

Move the riding mower’s PTO into the OFF

position.

10.

Turn the ignition key to the STOP position to

turn the riding mower’s engine OFF.

11.

Turn the water OFF and detach the hose

coupler (a) from the water port (c) on your

deck’s surface. See Figure 4-3.

12.

After cleaning your deck with the deck wash

system, return to the operator’s position

and engage the PTO. Keep the cutting deck

running for a minimum of two minutes,

allowing the underside of the cutting deck

to thoroughly dry.

Adjustments

WARNING

Never attempt to make any adjustments while the engine is

running, except where specified in the Operator’s Manual.

Seat

Refer to the Set-Up & Assembly section of this

manual for seat adjustment instructions.

Summary of Contents for 769-11837A

Page 20: ...Notes 4 ...

Page 40: ...Notas 20 ...