11

S

ection

5 — o

peration

Using the Log Splitter

NOTE:

Always operate on level ground, otherwise fluid may be

forced out through the air vent hole.

1.

Block the front and back of both wheels.

2.

Place the log against the splitting wedge. Only split wood

in the direction of the grain.

3.

Stabilize the log — if needed — with your left hand on

the side of the log only. Never place a hand on the end

between the log and the ram.

NOTE:

Only one adult should stabilize the log and operate

the hydraulic valve control so that the operator has full

control over the log and the ram.

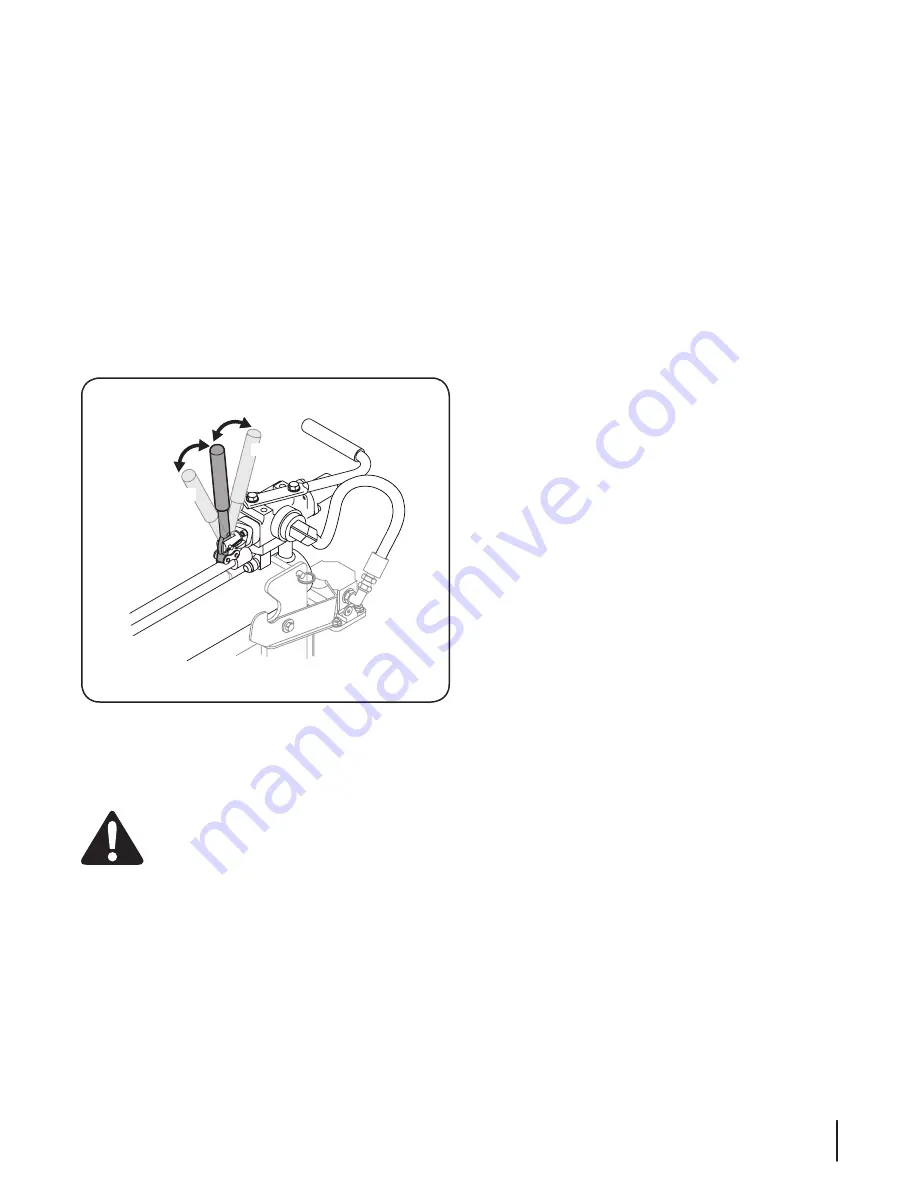

4.

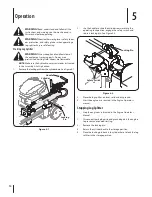

Move the hydraulic valve control FORWARD until the ram

touches the log. Release the hydraulic valve control to

NEUTRAL position to stop the ram movement. See Figure 5-3.

Forward

Neutral

Reverse

Figure 5-3

5.

Remove your left hand from the log. Move the hydraulic

valve control FORWARD to split the log.

6.

Move the hydraulic valve control BACK to fully retract the

ram to the locked position.

WARNING!

Never remove partially split wood from

the wedge with your hands. Your fingers may

become trapped between the split wood.

Operating Tips

Always:

1.

Use clean fluid and check fluid level regularly.

2.

Use an approved hydraulic fluid. Approved fluids include

Dexron® III, or a 10 Weight AW hydraulic oil.

3.

Keep hoses clear and unblocked.

4.

Use the hydraulic valve control to extend and retract

cylinder 4-6 cycles to remove trapped air in the system

before operating.

5.

Flush and clean hydraulic system before restarting after

servicing.

6.

Use “pipe dope” on all hydraulic fittings.

7.

Operate on level ground.

8.

Allow time for warm-up before splitting wood.

9.

Prime the pump before initial start-up by pulling the recoil

starter on the engine 4-6 times with engine switch in OFF

position and spark plug disconnected.

10. Split the wood along the grain (lengthwise) only.

11. Keep log centered in front of ram.

Never:

1.

Use when fluid is below 20° F or above 150° F.

2.

Operate in FORWARD or REVERSE position with the ram

stopped for extended an period.

3.

Attempt to adjust the unloading or the relief valve settings.

4.

Operate with air in the hydraulic system.

5.

Use Teflon tape on the hydraulic fittings.

6.

Attempt to cut wood across the grain.

7.

Attempt to remove partially split wood from the wedge

with your hands.