Service

7

13

Belt Replacement

WARNING!

Be sure to shut the engine off, disconnect

the spark plug wire and ground it against the engine to

prevent unintended starting before removing the belt.

The belt on your log splitter is subject to wear and should be

replaced if any signs of wear are present.

NOTE:

The V-belt found on your log splitter is a non-clutching,

constant tension belt. A substitute (non- OEM) V-belt can

be dangerous. For a proper working machine, use factory

approved belts.

To change or replace the belt on your log splitter, proceed as

follows:

NOTE:

This procedure requires the assistance of a second

person.

1.

Place the log splitter in the transport position with the

cylinder in the storage position and on level ground.

2.

Disconnect the spark plug wire and ground it against the

engine.

3.

Drain the gasoline as instructed in the Engine Operator’s

Manual or place a piece of plastic beneath the gas cap to

prevent any gasoline leakage.

4.

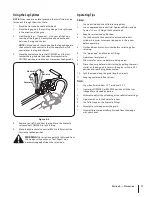

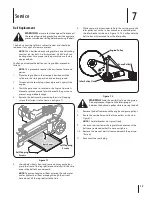

Remove the belt cover by removing the six self-tapping

screws that fasten it to the frame. See Figure 7-1.

Self-Tapping

Screws

Self-Tapping

Screws

Belt Cover

Figure 7-1

5.

Chock both wheels, front and rear, and have your helper

grasp the front of the log splitter and carefully tilt it back to

expose the belt drive underneath.

NOTE:

To prevent engine oil from entering the carburetor

and/or hydraulic oil from escaping through the air vent

hole, do not tilt the log splitter to the side.

6.

While your partner continues to hold the unit up, grasp the

idler pulley nut with a 9⁄16 hex wrench or socket and pivot

the idler bracket as shown in Figure 7-2. This will enable the

belt to be easily removed from the idler pulley.

Engine Pulley

Idler Pulley Nut

Pump Pulley

Figure 7-2

WARNING!

Avoid the possibility of a pinching injury.

Do not place your fingers on the idler spring or

between the belt and a pulley while removing the belt.

7.

Remove the belt from around the engine and pump pulleys.

8.

Route the new belt around the three pulleys as shown in

Figure 7-2.

NOTE:

The idler bracket must pivot freely.

9.

Have your partner lower the log splitter and remount the

belt cover removed earlier. Do not over tighten.

10. Remove the piece of plastic from underneath the gas cap

(if used).

11. Reconnect the spark plug.