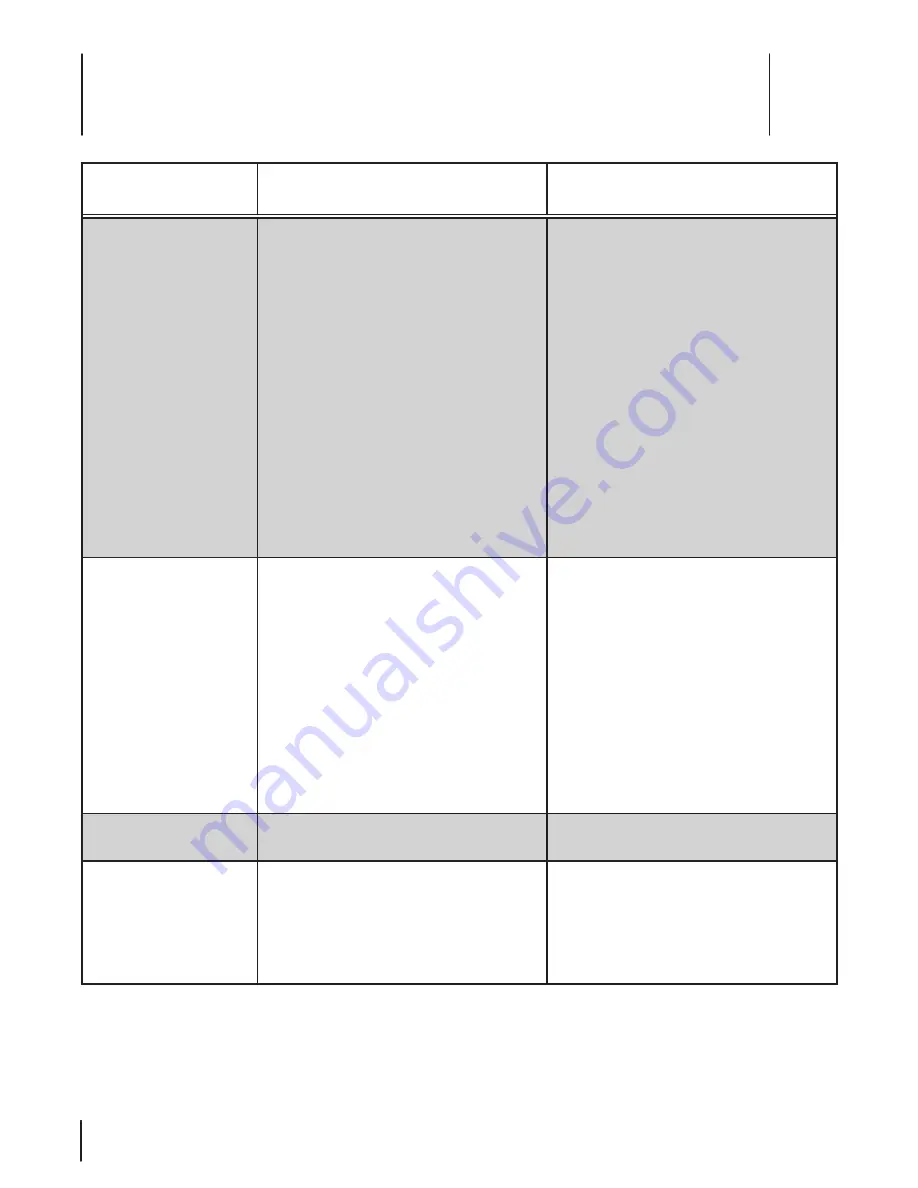

Troubleshooting

8

14

Problem

Cause

Remedy

Cylinder rod will not move

1. Broken or worn belt.

2. Shipping plugs left in hydraulic hoses.

3. Set screws in pump pulley not adjusted

properly.

4. Loose pulley.

5. Pump gear sections damaged.

6. Damaged relief valve.

7. Hydraulic lines blocked.

8. Incorrect oil level.

9. Damaged directional valve.

10. Blocked directional valve.

11. Un-level ground; hydraulic fluid not reaching

pump.

1. Replace belt.

2. Disconnect hydraulic hoses, remove shipping

plugs, reconnect hoses.

3. See authorized service dealer.

4. Correct engine/pump alignment as

necessary.

5. See authorized service dealer.

6. See authorized service dealer.

7. Flush and clean hydraulic system.

8. Check oil level.

9. See authorized service dealer.

10. Flush and clean hydraulic system.

11. Move log splitter to level ground.

Slow cylinder shaft speed

while extending and

retracting.

1. Gear sections damaged.

2. Excessive pump inlet vacuum.

3. Slow engine speed.

4. Damaged relief valve.

5. Incorrect oil level.

6. Contaminated oil.

7. Directional valve leaking internally.

8. Internally damaged cylinder.

9. Log Splitter not on level ground.

1. See authorized service dealer.

2. Make certain pump inlet hoses are clear and

unblocked, use short, large diameter inlet

hoses.

3. See authorized service dealer.

4. See authorized service dealer.

5. Check oil level.

6. Drain oil, clean reservoir, and refill.

7. See authorized service dealer.

8. See authorized service dealer.

9. Move log splitter to level ground.

Leaking Cylinder

1. Broken seals.

2. Scored cylinder.

1. See authorized service dealer.

2. See authorized service dealer.

Leaking pump shaft seal

1. Broken drive shaft.

2. Engine/pump misalignment.

3. Gear sections damaged.

4. Poorly positioned shaft seal.

5. Plugged oil breather.

1. See authorized service dealer.

2. Correct alignment as necessary.

3. See authorized service dealer.

4. See authorized service dealer.

5. Make certain reservoir is properly vented.