4

SECTION 2: ASSEMBLY & OPERATION

NOTE:

References to LEFT, RIGHT, FRONT and

REAR of the tractor are from the operator’s position.

•

Before

assembly, place the tractor on a firm, level

surface, disengage the PTO, stop the tractor

engine and set the parking brake.

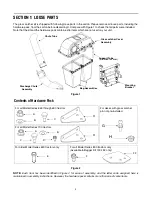

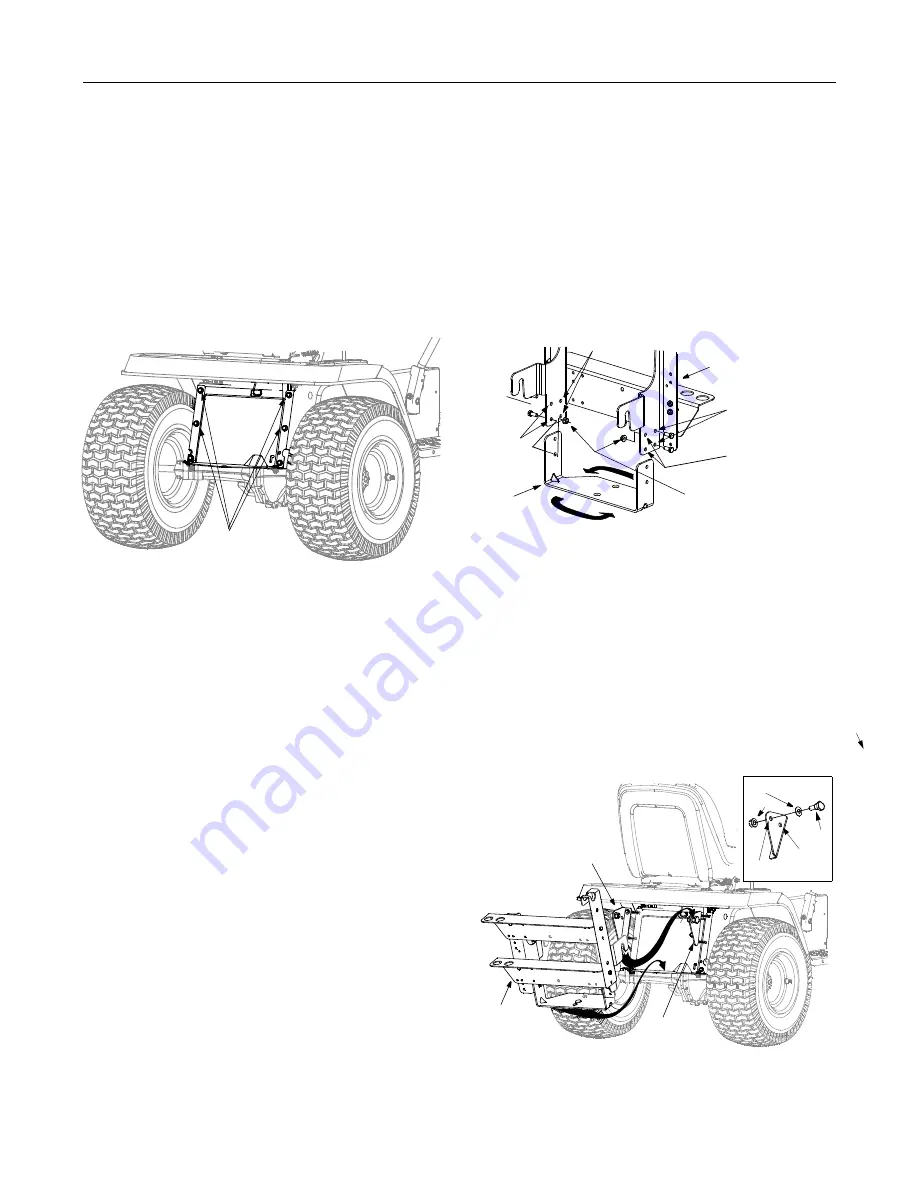

Assembling Support Brackets

Tractor Model Series 660 through 690

•

Remove the top four self-tapping screws from the

rear of the lawn tractor. See Figure 3.

Figure 3

•

Place the right hand grass catcher support bracket

(F1 from Figure 2) in position as shown in Figure 5.

•

Secure the support bracket to the tractor frame with

two self-tapping screws earlier removed. Refer to

Figure 3. Repeat on the other side.

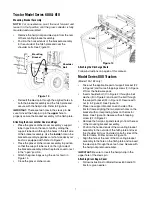

Tractor Model Series700

•

Use the four self-tapping screws supplied in your

hardware pack (D from Figure 2).

•

Place the right hand grass catcher support bracket

(F1 from Figure 2) in position as shown in Figure 5.

Secure each support bracket to the tractor frame with

two self-tapping screws supplied in your hardware

pack. Refer to Figure 5. Repeat on the other side.

NOTE:

If the grass collection system is removed for any

reason, it is not necessary to remove the support

brackets from the tractor.

Tractor Model Series 660 through 690

•

Insert a shoulder bolt (C in Figure 2) through a bell

washer, (B in Figure 2) and insert the bolt through

the

upper hole

on the support bracket. Secure with

a nut (A in Figure 2). See Figure 5 inset for details.

Repeat on other side.

Tractor Model Series700

•

Insert a shoulder bolt (C in Figure 2) through a bell

washer, (B in Figure 2) and insert the bolt through

the

lower hole

on the support bracket. Secure with

a nut (A in Figure 2). See Figure 5 inset for details.

Repeat on other side.

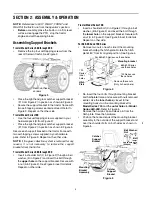

For 660-690 and 700 Series

•

Remove two nuts on each side of the mounting

bracket holding the hitch plate. Rotate the hitch

plate 180° from its original position. See Figure 4.

Figure 4

•

Re-insert the four bolts through mounting bracket

and hitchplate frame and secure with nuts removed

earlier. Use the

inner holes

(closest to the

mounting hooks) on the mounting bracket

for

Model Series 700

and the

outer holes

for

Model

Series 660-690.

Refer to Figure 4.

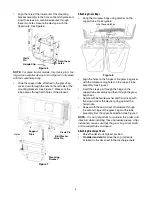

•

Remove the hairpin clip and clevis pin from the

hitch plate. Save the hardware.

•

Position the hooked ends of the mounting bracket

assembly to the outside of the support bracket and

over the shoulder bolts on both sides as shown in

Figure 5.

Figure 5

Remove these

screws

Remove these nuts

(Only 2 shown here)

Plate

Hitch

660-690 Series

use these holes

700 Series use

these holes

For 660-690 Series use these holes

700

Series

Mounting bracket

inner

holes

Catcher

Bracket

Support

Catcher

Bracket

Support

Mounting

Bracket

Assembly

Nut

Bolt

Bell Washer

(660-690)

lower

(700)

hole

upper hole

Summary of Contents for OEM-190-180

Page 9: ...9 NOTES ...