13

SECTION 9: ADJUSTMENTS

WARNING:

Do not at any time make

any adjustment to lawn mower without

first stopping engine and disconnecting

spark plug wire.

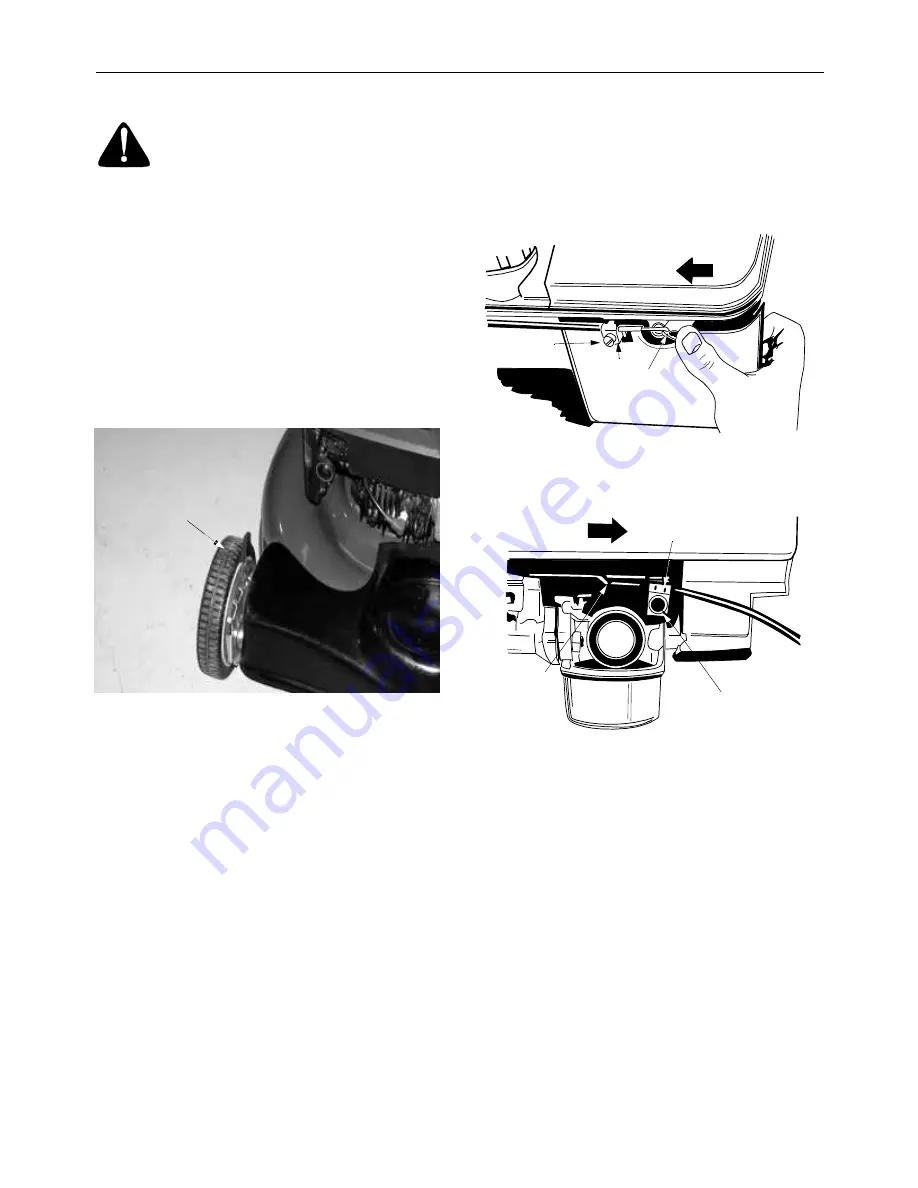

CUTTING HEIGHT ADJUSTMENT

An adjusting plate and lever at each wheel position

provides cutting height adjustment. Each adjusting

plate has nine height positions. Height of cut will be

changed when the lever is moved from one position

to another. Simply depress the lever towards wheel

and move wheel and lever assembly to desired

position. All wheels must be placed in the same

relative position. See Figure 12.

Figure 12

THROTTLE CONTROL ADJUSTMENT

NOTE:

Your unit may be a constant speed engine,

which is set at full throttle for best performance. This

engine requires no throttle adjustment.

If you have a unit with a the throttle control which

needs adjustment or if it has been replaced, adjust

as follows.

1.

Remove the screw shown in Figure 13. Remove

the cable clamp from the cable.

NOTE:

If you have a Tecumseh engine, simply

loosen the screw shown in Figure 14 so the cable

will move freely beneath the clamp. It is not

necessary to remove the screw and clamp

completely.

2.

Push the throttle control lever on the handle all

the way forward as far as it will go, then back it

off one “click.” Make certain the throttle control

lever remains in this position.

3.

Push the control lever on the engine as far

toward the rear of the engine as it will go.

Secure the cable in this position with the cable

clamp and screw.

Figure 13

Figure 14

DRIVE CLUTCH ADJUSTMENT

The drive clutch control adjustment wheel is located

in the drive clutch control handle housing and is

used to tighten or loosen the drive belt. You will

have to adjust the drive clutch control if any of the

following happens:

• The mower does not propel itself with the

drive clutch engaged.

• The mower’s drive wheels hesitate with the

drive clutch engaged.

To resolve the above problems, rotate the adjust-

ment wheel with your fingers. Clockwise to tighten

the cable and counter-clockwise to loosen the cable.

See Figure 15.

Height

Adjuster

Lever

Screw

Cable

Clamp Control

Lever on

Engine

Briggs & Stratton Quantum Engines

Control

Lever

On Engine

Screw

Cable

Clamp

Tecumseh Engines