2SHUDWLQJ LQVWUXFWLRQV 0RWRU +RHV

English

5

The symbols have the following

meanings:

Attention! Please

read the operating

instructions before

putting appliance into

operation!

Danger of injury from

rotating parts. Keep

hands and feet well

away from rotating

parts.

Always keep these symbols on the

appliance in a legible state.

7]QFSPWMRXLIYWIVkWKYMHI

Symbols are employed in the user’s

guide to indicate hazards or draw

attention to important information.

They have the following specific

meanings:

(ERKIV

(VE[W]SYVEXXIRXMSRXSWSYVGIWSJ

TSXIRXMEPHERKIVEWWSGMEXIH[MXLXLI

XEWO]SYEVIYRHIVXEOMRKEXXLIXMQI

[LMGLGSRWXMXYXIEHERKIVXSTIVWSRW

'EYXMSR

9WIHXSLMKLPMKLXLE^EVHW[LMGLEVI

EWWSGMEXIH[MXLXLIEGXMZMX]XLEXMW

FIMRKHIWGVMFIH[LIVIF]HEQEKI

GSYPHSGGYVXSXLIETTPMERGI

2SXI

This indicates important information

and application tips.

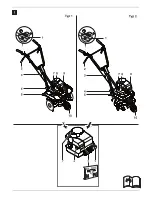

9RTEGOMRK%WWIQFP]

'EYXMSR

(EQEKIHGEFPIWIXWGERPIEHXS

JEYPX]STIVEXMSRSJXLIQEGLMRI

;LIRYRTEGOMRKXLIQEGLMRIFI

GEVIJYPXLEXXLIWITEVXWHSRSKIX

FYGOPIHSVWUYEWLIH

When unpacking, check the

supplied contents. At the end of the

operating instructions or as a

supplement the assembly of the

appliance is presented in pictures.

&IJSVIJMVWXYWI

'EYXMSR

*SVXLITYVTSWISJXVERWTSVXEXMSR

XLIQEGLMRIMWWYTTPMIH[MXLSYX

IRKMRISMP

&IJSVIYWMRKXLIQEGLMRIJSVXLIJMVWX

XMQIJMPPYT[MXLIRKMRISMPWII

WITEVEXIIRKMRIMRWXVYGXMSRW

3TIVEXMRK

%PWSJSPPS[XLIMRWXVYGXMSRWMRXLI

IRKMRILERHFSSO

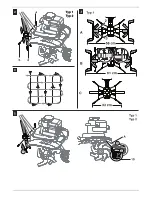

7IXXLILSIMRKHITXL

Figure

The tilling depth can be set by adju-

sting the depth gauge (4).

7IXHITXLGSRXVSPPMRKFEV

Figure

■

Undo spring connector (

E

) and

bolt (

F

).

■

Set depth-controlling bar (4).

The lower the bar, the deeper

and slower the machine hoes.

■

Secure depth-controlling bar with

bolt and spring connector.

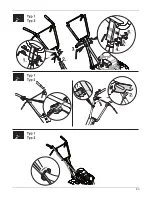

7IXXMRKXLIXVERWTSVXEXMSR

[LIIP

The transportation wheel (10) has

been set at the factory so that the

unit is positioned horizontally when

in an idle state. The tiller cannot be

operated until the wheel is moved

upwards.

8MPPMRK

Figure

■

Pull wheel holder (

%

) and press

upwards until it engages in the

tilling position.

■

Check that the wheel holder

engages correctly.

8VERWTSVXMRK

Figure

■

Pull wheel holder (

%

) and press

downwards until it engages in the

transport position.

■

Check that the wheel holder

engages correctly.

7IXKYMHMRKFEV

7IXLIMKLX

Figure

■

Undo lever/handle (3).

■

Set guiding bar at required height.

■

Tighten lever/handle again.

7IXLSIMRK[MHXL

8]TISRP]

Figure

(ERKIVSJMRNYV]

&IJSVIQEOMRKWIXXMRKWSRXLI

LSIMRKFPEHIW

r 7[MXGLSJJXLIIRKMRI

r ;EMXYRXMPEPPQSZMRKTEVXWLEZI

GSQIXSEWXERHWXMPPERHXLI

IRKMRILEWGSSPIHHS[R

r 6IQSZIXLIWTEVOTPYKXIVQMREP

;SVOZIV]GEVIJYPP]

By adjusting or dismounting the

hoeing blades, three different hoeing

widths can be set.

*EGXSV]WIXXMRK

■

Width 61 cm (B): undo spring

connector (2) and bolt (3), pull out

both outer blade pairs to the outer

holes and secure with bolts and

spring connectors.

■

Width 33 cm (C): undo spring

connector (2) and bolt (3), remove

both outer blade pairs.

2SXI

On Type 2 the tilling width cannot be

adjusted.

*MPPYT[MXLTIXVSPERH

GLIGOSMPPIZIP

(ERKIVSJI\TPSWMSRERHJMVI

%P[E]WJMPPYTMRXLISTIREMVERH[MXL

EW[MXGLIHSJJERHGSPHIRKMRI

2IZIVWQSOI[LIRJMPPMRKYT

2IZIVJMPPYTGSQTPIXIP]-JJYIP

SZIVJPS[WEPPS[XLISZIVJPS[XS

IZETSVEXIFIJSVIWXEVXMRK

!

!

Hoeing width in cm

Purpose

56 *)

Hoeing

61

33

Cultivation

!

!

Summary of Contents for Tiller

Page 1: ...18 4VSHYGXW OXMIRKIWIPPWGLEJX 7EEVFVµGOIR IVQER 361 23 ...

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ... RKPMWL VER EMW IYXWGL 2IHIVPERHW XEPMERS WTE SP 7ZIRWOE ERWO 2SVWO 7YSQM 4SVXYKYÂW r w ...

Page 7: ... ...

Page 8: ... ...