16

NOTE: SplitLine™ can only be used with the inner reel

containing the slotted holes. Single line can be

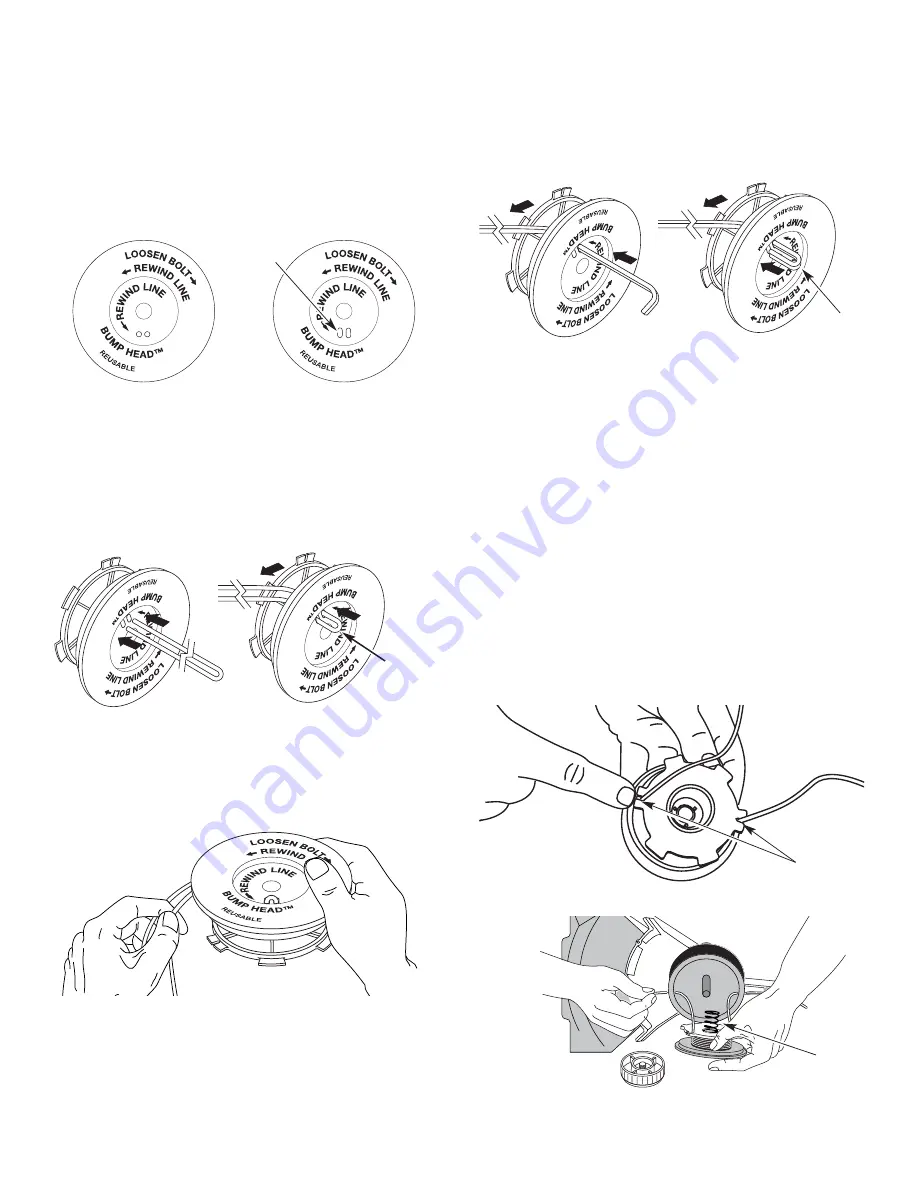

used on either type of inner reel. Use Figure 27

to identify the inner reel you have.

NOTE: Always use the correct line length when installing

trimming line on the unit. The line may not

release properly if the line is too long.

Single Line Installation

Go To Step 8 for SplitLine™ Installation

6. Take approximately 30 feet (9.14 m) of new trimming

line, loop it into two equal lengths. Insert each end of

the line through one of the two holes in the inner

reel, Figure 28. Pull the line through the inner reel so

that the loop is as small as possible.

Loop

Slotted

Holes

For Use with SplitLine™

or Single Line

For Use with

Single Line ONLY

Loop

7. Wind the lines in tight even layers, onto the reel,

Figure 29. Wind the line in the direction indicated on

the inner reel. Place your index finger between the

two lines to stop the lines from overlapping. Do not

overlap the ends of the line. Proceed to step 11.

Spring

Holding Slots

9. Insert the end of the line into the open hole in the

inner reel and pull the line tight to make the loop as

small as possible, Figure 30.

10. Before winding, split the line back about 6 inches.

11. Wind the line in tight even layers in the direction

indicated on the inner reel.

NOTE: Failure to wind the line in the direction indicated

will cause the cutting attachment to operate

incorrectly.

12. Insert the ends of the line into the two holding slots,

Figure 31.

13. Insert the ends of the line through the eyelets in the

outer spool and place inner reel with spring inside

the outer spool, Figure 32. Push the inner reel and

outer spool together. While holding the inner reel and

outer spool, grasp the ends and pull firmly to release

the line from the holding slots in the reel.

NOTE: The spring must be assembled on the inner reel

before reassembling the cutting attachment.

14. Hold the inner reel in place and install the bump

knob by turning counterclockwise. Tighten securely.

FIGURE 27

FIGURE 28

FIGURE 29

FIGURE 30

FIGURE 31

SplitLine™ Installation

8. Take approximately 15 feet (4.57 m) of new trimming

line. Insert one end of the line through one of the two

holes in the inner reel, Figure 30. Pull the line through

the inner reel until only about 4 inches are left out.

FIGURE 32