HYDROCAL 1001+ Installation and operation manual

Page 10/76

2.4.

Installation

After the installation preparation is completed, the HYDROCAL unit can be installed. The installation

is divided into 3 steps:

Mechanical installation

(2.4.1)

Electrical connection

(2.4.2)

Putting into operation

(2.4.3)

2.4.1.

Mechanical installation

The sequence of the mechanical installation depends on which connection type is available on the

transformer side. There are basically 2 types of mechanical installation:

Direct installation

(2.4.1.1)

Indirect installation

(2.4.1.2)

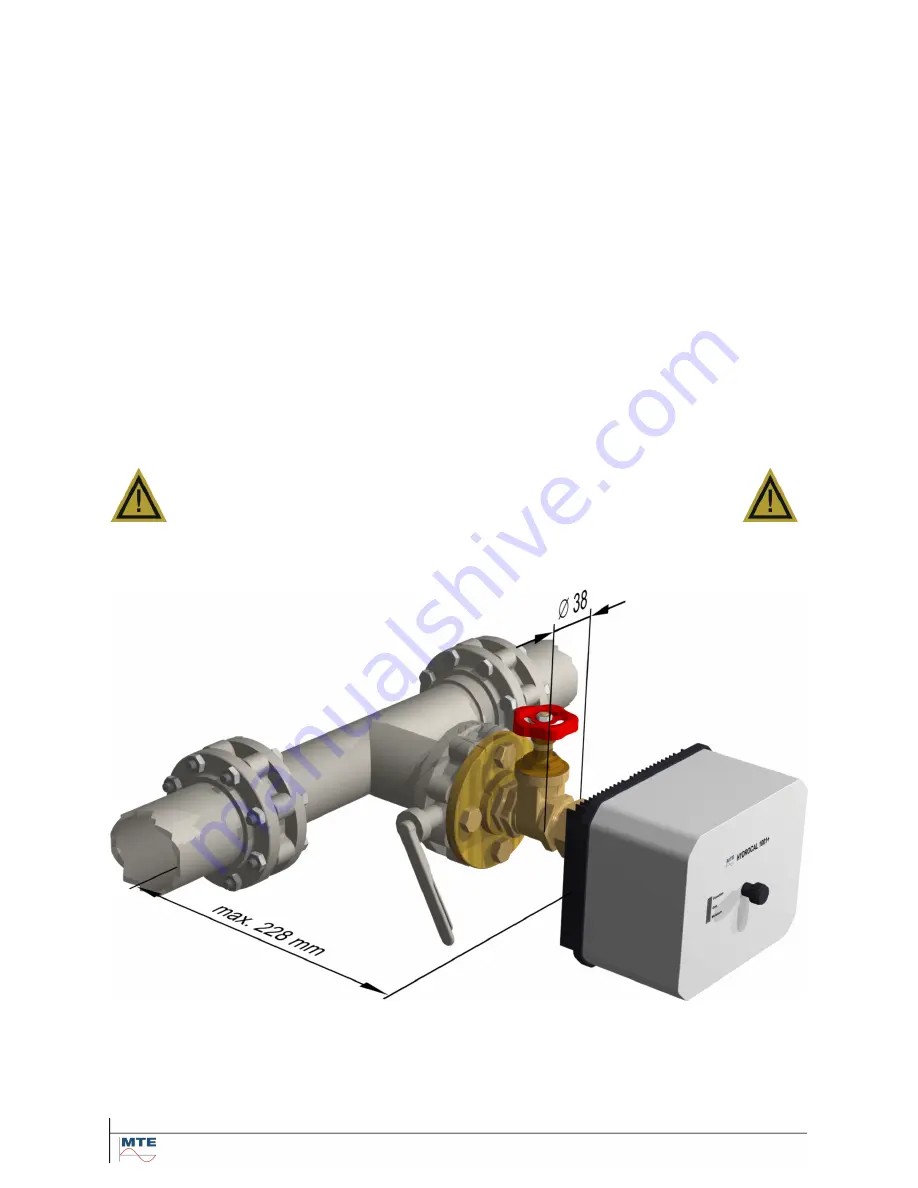

Note:

In case there are strong vibrations on the connection valve, the valve should be relieved by a

support.

A good oil flux should exist on the installation position. If necessary, use a reduction piece (adapter).

In order to have a sufficient oil flux on the membrane, the diameter of the valve should be not less

than 25 mm. For optimal working conditions, the valve diameter should not be more than 76 mm. The

valve must be on earth potential.

Attention!!!

The distance between the oil main stream and the backplate unit shall not

be more than 6 times the length of valve diameter.

(Distance 150 mm at Valve-

25 mm / Distance 228 mm at Valve-

38 mm /

Distance 300mm at Valve-

50 mm / Distance 450mm at Valve-

76 mm).