Temposonics

®

E-Series CANopen

Operation Manual

18

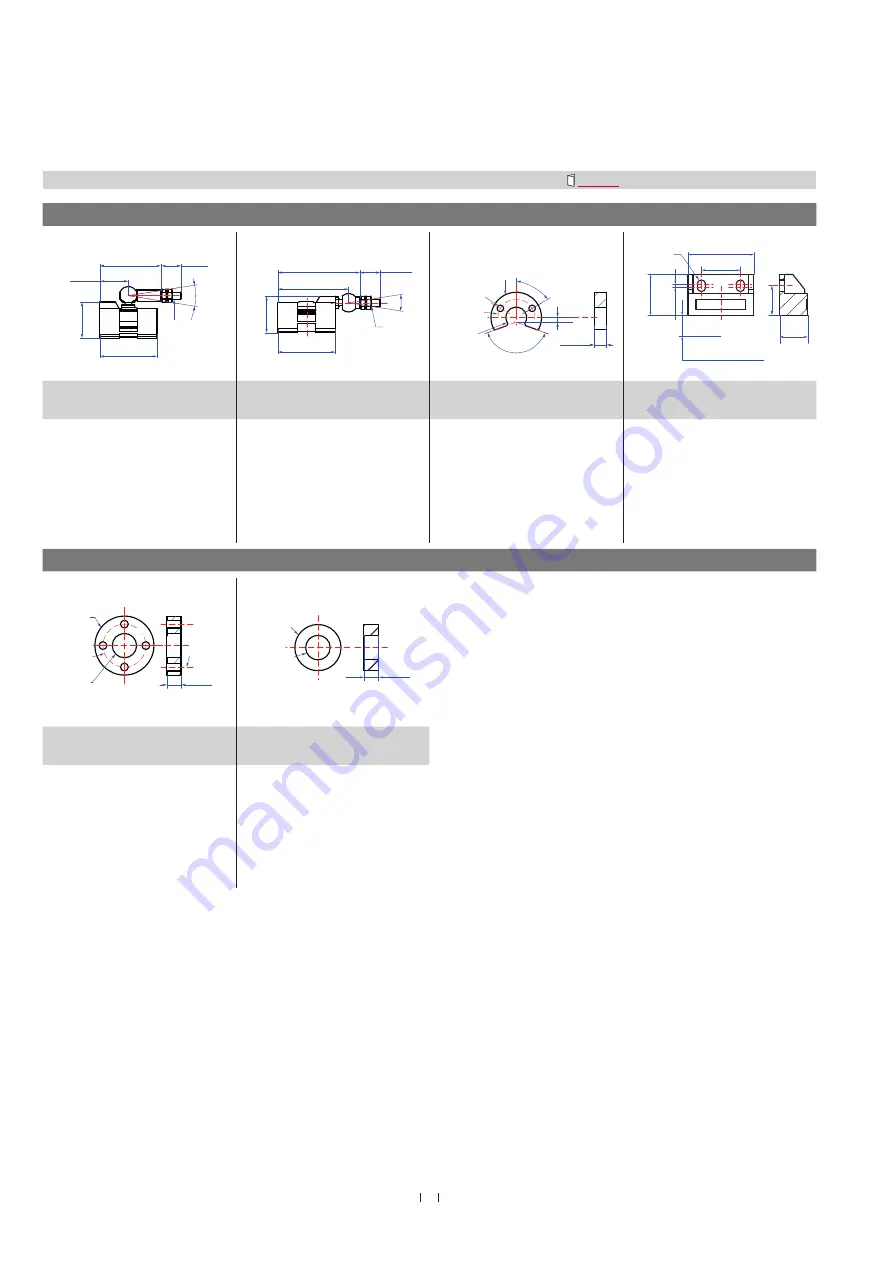

Position magnets

M5

20

(0.79)

43

(1.69)

14

(0.55)

40 (1.58)

18°

25.3 (1)

M5

40 (1.58)

18°

57 (2.24)

14

(0.55)

25.3 (1)

49 (1.93)

Ø 32.8

(Ø 1.29)

Ø 23.8

(Ø 0.94)

Ø 13.5

(Ø 0.53)

Ø 4.3

(Ø 0.17)

60°

140°

3 (0.12)

7.9

(0.31)

19,5 (0.77)

1,5 (0.06)

33 (1.3)

14

(0.55)

20,5 (0.81)

14,9 (0.59)

8 ± 2 (0.31 ± 0.08)

Space sensor element

Ø 4.3

(Ø 0.17)

Magnet slider S

Part no. 252 182

Magnet slider V

Part no. 252 184

U-magnet OD33

Part no. 251 416-2

Block magnet

Part no. 403 448

For:

EP and EL

Material: GFK, magnet hard ferrite

Weight: Ca. 35 g

Operating temperature: −40…+75 °C

(−40…+167 °F)

For:

EP and EL

Material: GFK, magnet hard ferrite

Weight: Ca. 35 g

Operating temperature: −40…+75 °C

(−40…+167 °F)

For:

EP and EH

Material: PA ferrite

Weight: Ca. 11 g

Surface pressure: max. 40 N/mm

2

Fastening torque for M4 screws:

Max. 1 Nm

Operating temperature: −40…+105 °C

(−40…+221 °F)

For:

EP, EL and EH

Material: hard ferrite

Weight: Ca. 20 g

Operating temperature: −40…+75 °C

(−40…+167 °F)

Fastening torque for M4 screws:

Max. 1 Nm

Position magnets

Ø 32.8

(Ø 1.29)

Ø 23.8

(Ø 0.94)

Ø 13.5

(Ø 0.53)

Ø 4.3

(Ø 0.17)

7.9

(0.31)

Ø 25.4

(Ø 1)

Ø 13.5

(Ø 0.53)

7.9

(0.31)

Ring magnet OD33

Part no. 201 542-2

Ring magnet OD25,4

Part no. 400 533

For:

EH

Material: PA ferrite GF20

Weight: Ca. 14 g

Surface pressure: max. 40 N/mm

2

Fastening torque for M4 screws:

Max. 1 Nm

Operating temperature: −40…+105 °C

(−40…+221 °F)

For:

EH

Material: PA ferrite

Weight: Ca. 10 g

Surface pressure: Max. 40 N/mm

2

Operating temperature: −40…+105 °C

(−40…+221 °F)

Additional options available in our Accessories Guide 551444)

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

4.7 Frequently ordered accessories – Additional options available in our Accessories Guide