7.3.2 Cylinder liner – Instructions and comments on endoscopic and visual

examination

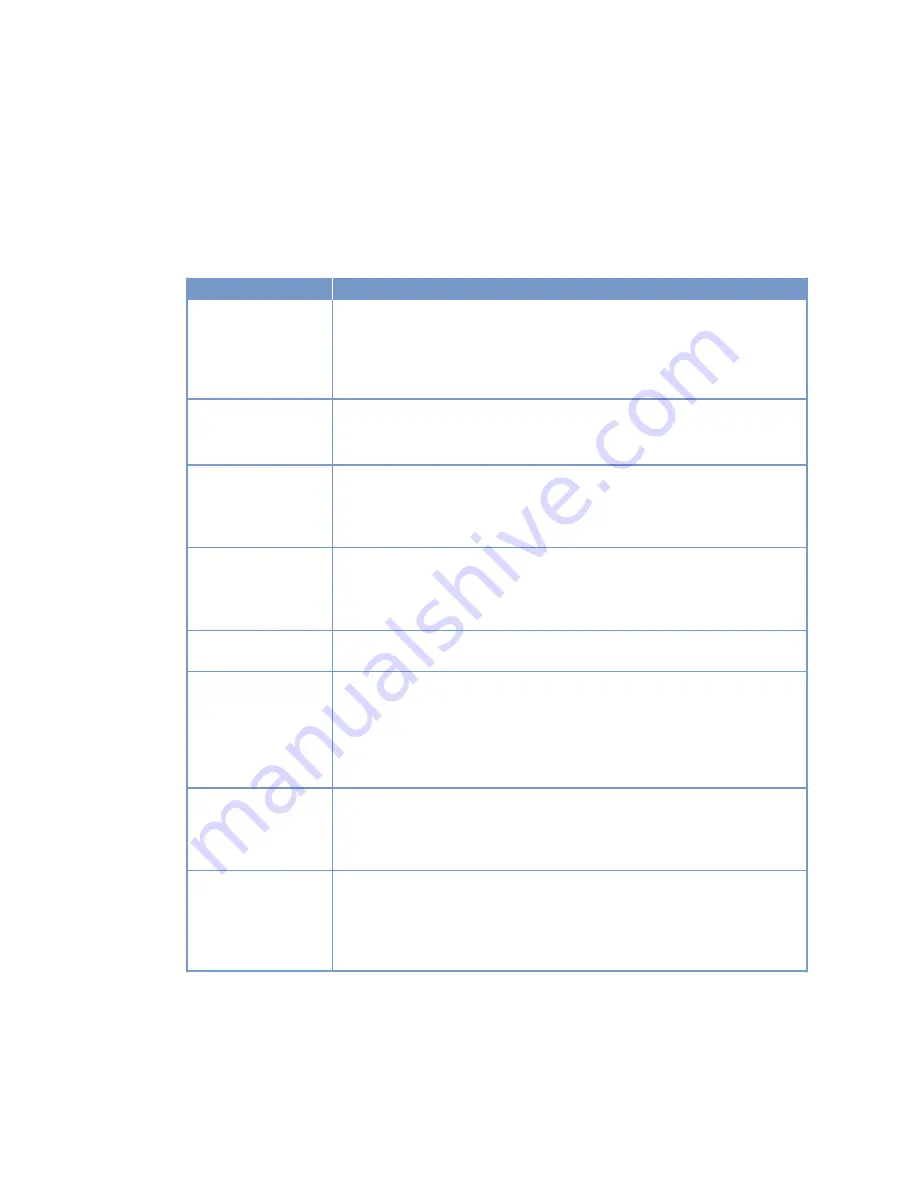

Terms used for endoscopic examination

Use the terms listed below to describe the condition of the cylinder-liner surface in the endoscopic exami‐

nation report.

Findings

Measure

Minor dirt scores

Minor dirt scores can occur during the assembly of a new engine (honing prod‐

ucts, particles, broken-off burrs). Removed cylinders clearly show such scoring

on the running surface under endoscope magnification. Cannot be felt with the

fingernail.

Findings not critical.

Single scores

Clearly visible scores caused by hard particles. They usually start in the TDC

area and cross through the hone pattern in the direction of stroke.

Findings not critical.

Scored area

These areas consist of scores of different length and depth next to one anoth‐

er. In most cases, they are found at the 6-o'clock and 12-o'clock positions (in‐

let/exhaust) along the transverse engine axis.

Findings not critical.

Smoothened area

Smoothened areas are on the running surface but almost the whole honing

pattern is still visible. Smoothened areas appear brighter and more brilliant

than the surrounding running surface.

Findings not critical.

Bright area

Bright areas are on the running surface and show local removal of the honing

pattern. Grooves from honing process are not visible any more.

Discoloration

This is caused by oxidation (surface discoloration through oil or fuel) and tem‐

perature differences around the liner. It appears rather darker within the honed

structure in contrast to the bright metallic running surface. The honing pattern

is undisturbed. Discolorations extend in stroke direction and may be interrupt‐

ed.

Findings not critical.

Corrosion fields / spots Corrosion fields / spots result from water (condensed water) with the valves in

the overlap (open) position. They are clearly visible due to the dark color of the

honing groove bottom.

This corrosion is not critical unless there is corrosion pitting.

Black lines

Black lines are a step towards heat discoloration. They are visible as a clear

discoloration from TDC to BDC in the running surface and the start of localized

damage to the honing pattern.

Cylinder liners with a large number of black lines around the running surface

have limited service life and should be replaced.

170 | Task Description | MW15550/06E 2012-02

TIM-ID: 0000000014 - 013

Summary of Contents for 12 V 2000 M50A

Page 21: ...Fuel system covers MW15550 06E 2012 02 General Information 21 TIM ID 0000002178 005 ...

Page 22: ...22 General Information MW15550 06E 2012 02 TIM ID 0000002178 005 ...

Page 23: ...Lube oil system covers MW15550 06E 2012 02 General Information 23 TIM ID 0000002178 005 ...

Page 24: ...24 General Information MW15550 06E 2012 02 TIM ID 0000002178 005 ...