7.3 Valve Drive

7.3.1 Valve clearance – Check and adjustment

Preconditions

☑

Engine is stopped and starting disabled.

☑

Engine coolant temperature is max. 40 °C.

☑

Valves are closed.

Special tools, Material, Spare parts

Designation / Use

Part No.

Qty.

Valve clearance gauge

Y4345893

1

Barring device

F6792910

1

Ratchet

F30006212

1

Double-end box wrench

F30002800

1

Offset screwdriver

F30453001

1

Socket wrench

F30030450

1

Torque wrench, 10-60 Nm

F30510423

1

Measuring device

Y4348409

1

Preparatory steps

1.

Install barring device (→ Page 92).

2.

Remove cylinder head cover (→ Page 98).

Move piston of cylinder A1 into

TDC position (without marking

on flywheel)

Note:

With cylinder head and valve gear installed.

1.

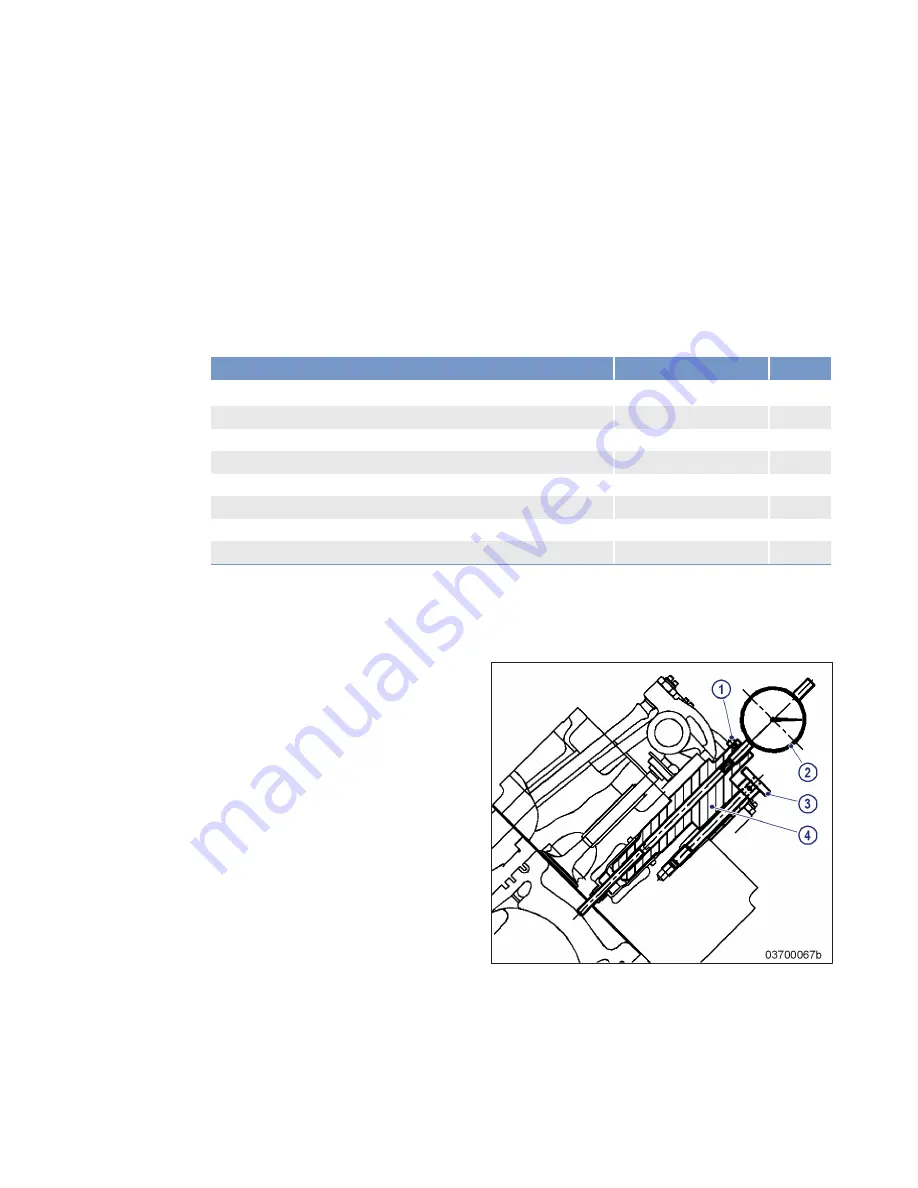

Insert preloaded dial gauge (2) into meas-

uring device (4) and clamp using screw (1).

2.

Install measuring device (4) in cylinder

head and secure using knurled screw (3).

3.

Zero dial gauge (2).

4.

Turn engine using barring device until pis-

ton A1 reaches firing TDC.

Result:

The piston is at firing TDC when both rock-

er arms are unloaded, i.e. have clearance.

Move piston of cylinder A1 into TDC position (without marking on flywheel)

1.

Unscrew plug screw on B-side of flywheel housing.

2.

Bar engine in direction of rotation until marking on flywheel is visible in the middle.

Result:

The piston is at firing TDC when both rocker arms are unloaded, i.e. have clearance.

MS150118/01E 2015-05

| Task Description | 95

TIM-ID: 0000053450 - 002