PEDAL FLANGER (MUTRON)

¾

CALIBRATION

PROCEDURES

PEDAL

SWEEP

RANGE

1.

For

best

results,

perform

this

procedure

away

from

direct

light

source.

2.

With

enclosure

positioned

on

its

side,

connect

voltmeter

to

TP6

(GND)

and

TP5

(Pedal

CV)

3.

Cover

entire

enclosure

with

dark

cloth

material

to

keep

ambient

light

from

reaching

LDRs

causing

inaccurate

readings.

4.

Engage

effect

switch

(SW1)

Engage

pedal

switch

(SW2)

5.

Adjust

TR7

(Coarse

adjust)

and

TR4

(Fine

adjust)

to

where

voltage

readings

are

approximately

11.60v

(toe

down)

and

2.29v

(heel

down)

6.

Due

to

variances

in

LEDs

and

LDRs,

It

may

be

necessary

to

adjust

D18,

LDR1,

LDR2

‐

up,

down,

right

or

left

to

achieve

the

target

voltages.

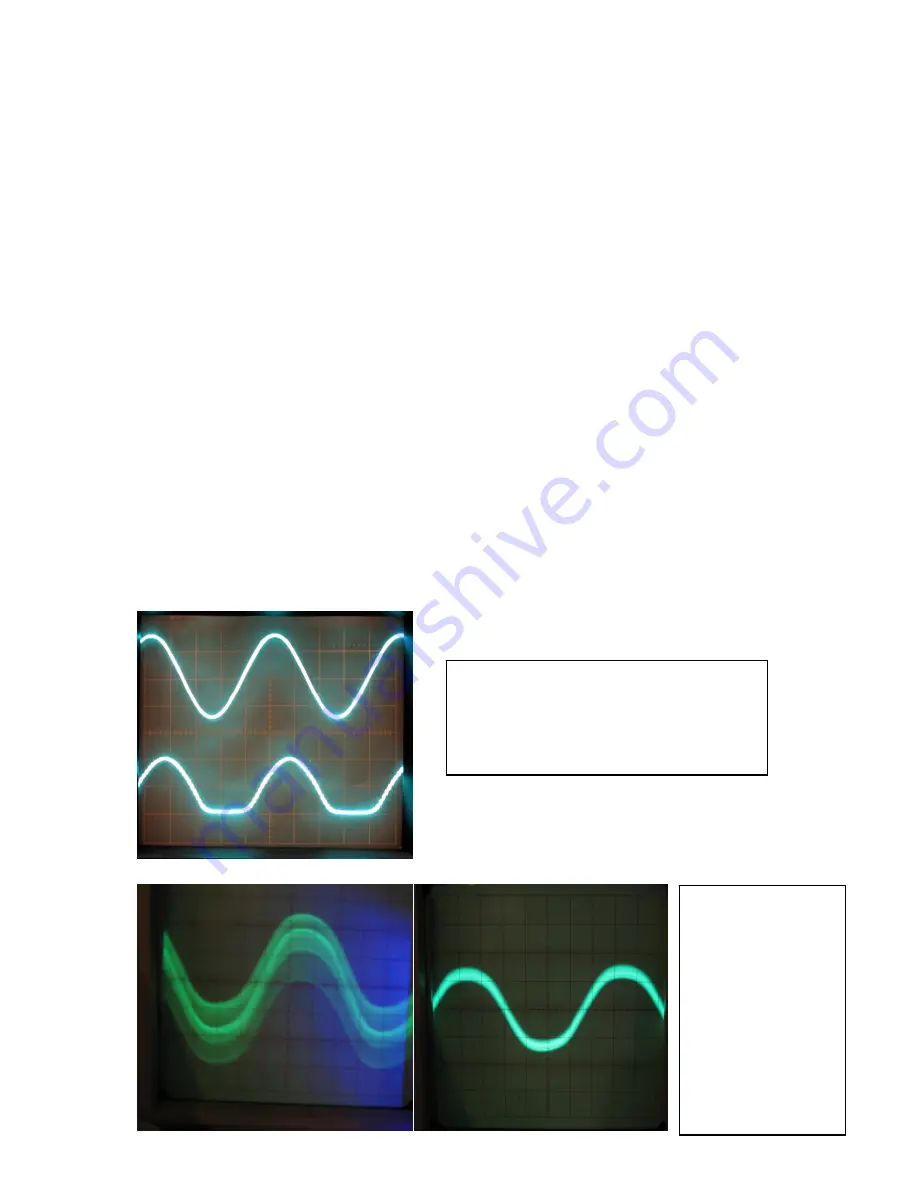

Fig.

1

Fig.

2

Fig.

3

Top

image

– Sine

wave

after

adjustment.

Bottom

image

–

Sine

wave

displaying

clipping.

Left

image

–

BBD

outputs

unbalanced.

Right

image

–

BBD

outputs

Balanced.

Summary of Contents for Pedal Flanger 3007

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ...PEDAL FLANGER MUTRON Main Board Overlay...

Page 10: ...5 32 in 6 50 in 134 5mm 164 7mm...

Page 11: ...111 6mm 4 41 in 3 54 in 89 9mm...

Page 18: ...4 5 6 1 2 3 9 8 7 4 5 6 1 2 3 SW2 SW1 PEDAL FLANGER MUTRON OFF BOARD WIRING LEGEND...

Page 34: ...Feedback Rate Start Stop Pedal Flanger 3007 Input Output Effect Pedal 12vac 18vdc...