BULLDOG 65 Hydraulic Steelworker

21

6.3

6.3

6.3

6.3

G

G

G

G

RINDING OF

RINDING OF

RINDING OF

RINDING OF

C

C

C

C

HANNEL

HANNEL

HANNEL

HANNEL

IIII

NSERT

NSERT

NSERT

NSERT

B

B

B

B

LADES

LADES

LADES

LADES

Body Blade

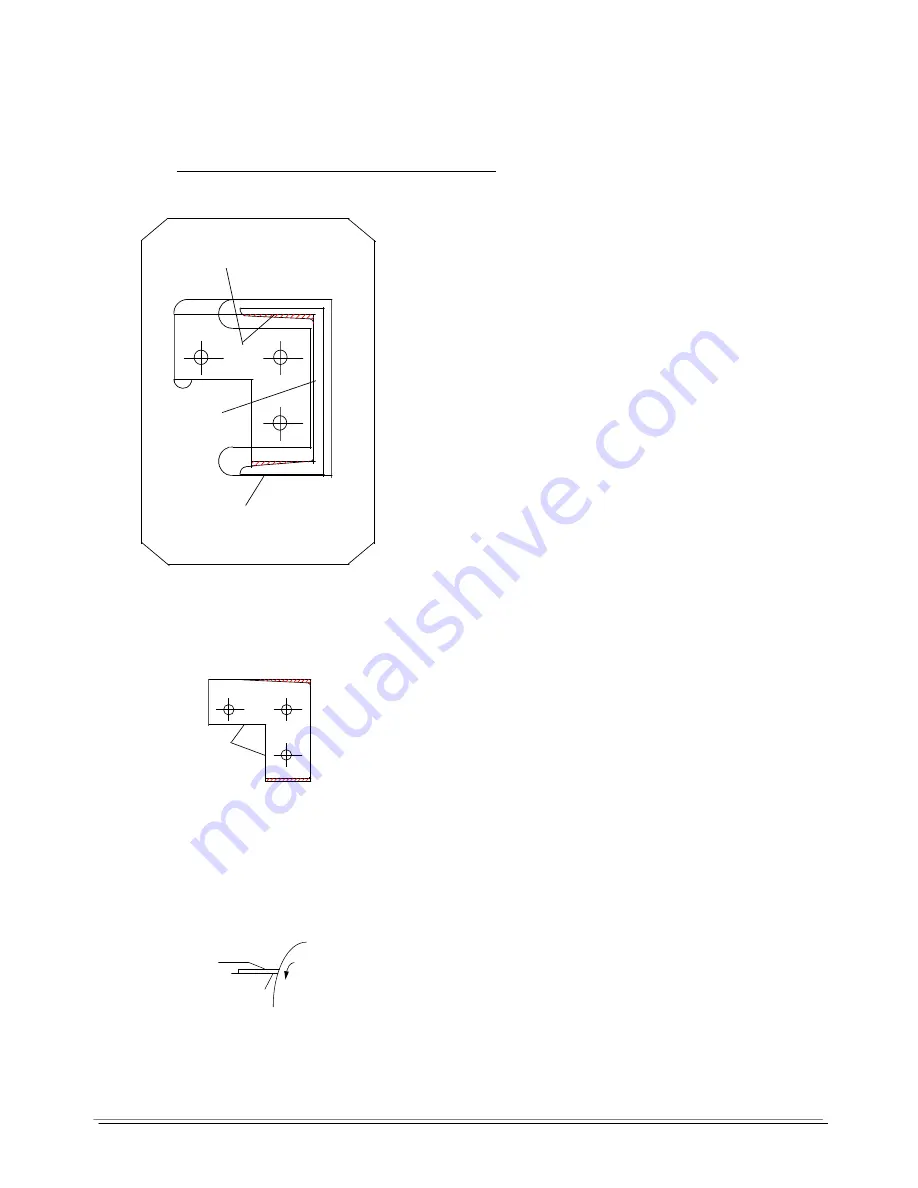

Fit blade to carrier, retain position with three screws,

ensure blade is seating on both faces, see sketch.

Mount a sample of channel, with a cleanly cut end,

on to the blade with the bottom flange in line with

bottom cutting face and the inside of the web square

and in line with the inside web cutting face, as

shown in sketch.

Having mounted channel correctly, scribe round inside of channel flanges.

•

Remove blade from carrier.

•

With ‘mark out’ A continue inner flange line as shown.

•

With ‘mark out’ B continue line from radius square to

cutting face. Allow a small clearance when grinding to

permit easy passage of channel.

Grinding

Grind insert blades to lines scribed, shown shaded in sketch.

When hand grinding, if using face of grinding wheel,

ensure angle between face of insert and cutting face

does not exceed 90 degrees.

Top Inside Flange cutting

Inside Web

cutting Face

Bottom Flange cutting

Blade must

seat squarely

on both faces

A

B

Face of

Insert