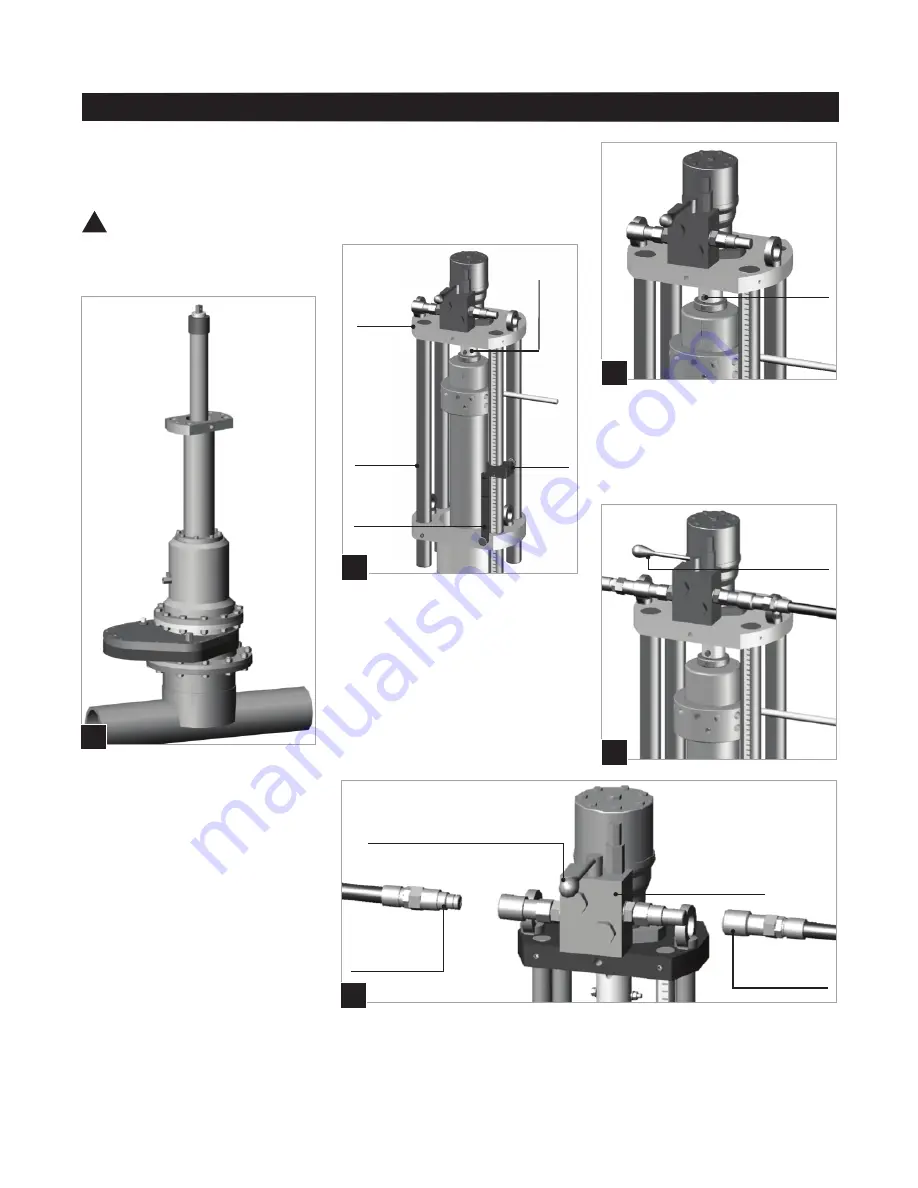

G.

Lever turned

90° clockwise:

shaft turns

clockwise

8. Remove the handles.

9. Position the motor support onto

the boring bar operating square.

Ensure guide columns are lined up

with housings (

D.

).

NOTE: There is an opening at the

very top of the shaft. This is to

allow the insertion of a pin, which

ensures that the motor support

bushing does not slide out (

e.

).

10. Connect the hoses coming from

the hydraulic control unit to the quick

couplings of the hydraulic operator

ensuring the lever is in the neutral

position (

F.

).

MUELLER

®

Shur Stop

TM

Unit 812 PE Line Stopping System

Operating Instructions

8

11. Start the hydraulic control unit.

12. Turn the hydraulic distributor

lever clockwise (

G.

).

13. Insert the removable handle in

the drilling machine.

5. Lift and position the drilling

machine onto the slide gate valve in

the open position. Tighten the bolts

in a criss-cross fashion (

C.

).

CAUTIoN: After each opening

and closing of the valve, remove

the operating wrench to prevent

accidental movement.

6. Insert the removable handles

7. Lower the shell cutter to the pipe

by using the removable handles

placed on the head of the drilling

machine, turning them clockwise

until contact is made with the

pilot drill on the pipe. When this

occurs, turn the feed tube a quarter

turn counter-clockwise to avoid

jamming when drilling begins.

!

C.

F.

Hydraulic

Distributor

Lever in Neutral Position:

Shaft Stopped

Pipe coming

from Hydraulic

Control Unit

Pipe coming

from Hydraulic

Control Unit

e.

Anti-

Slide

Pin

D.

Graduated

Scale

Collar

Motor

Support

Bushing with

Control Screw

Guiding

Columns