MUELLER

®

Shur Stop

TM

Unit 812 PE Line Stopping System

Operating Instructions

9

14. Use the removable handle,

turning it clockwise to begin drilling

(

h.

)

15. When the removable handle

comes into contact with the guiding

column insert the second handle

into the previous openings and

simultaneously slide out the first one.

Continue in this way until the drilling

is complete.

16. When the cutter shell makes

contact with the pipe, turn off the

hydraulic operator and stop drilling.

17. Loosen the knob on the

graduated scale.

18. Turn the graduated scale 90°

clockwise.

19. Then turn the knob on the

graduated scale until it is tight (

i.

)

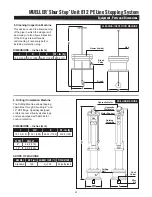

20. Loosen the collar using the knob.

21. Move the collar down to bring

the lower part (indicated by the tip

of the arrow) in correspondence to

the line below the diameter of the

pipe on which the operation is being

carried out (

J.

).

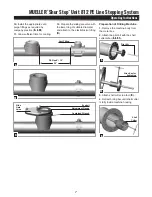

22. Loosen the knob on the

graduated scale, turn the graduated

scale 90° counter-clockwise and

then tighten the knob (

K.

).

J.

Collar

23. Open the oil flow and begin

drilling again, until the pipe coupon

detaches. The location of the collar

indicates the farthest travel the

machine can be operated safely,

without contacting the bottom of the

pipe.

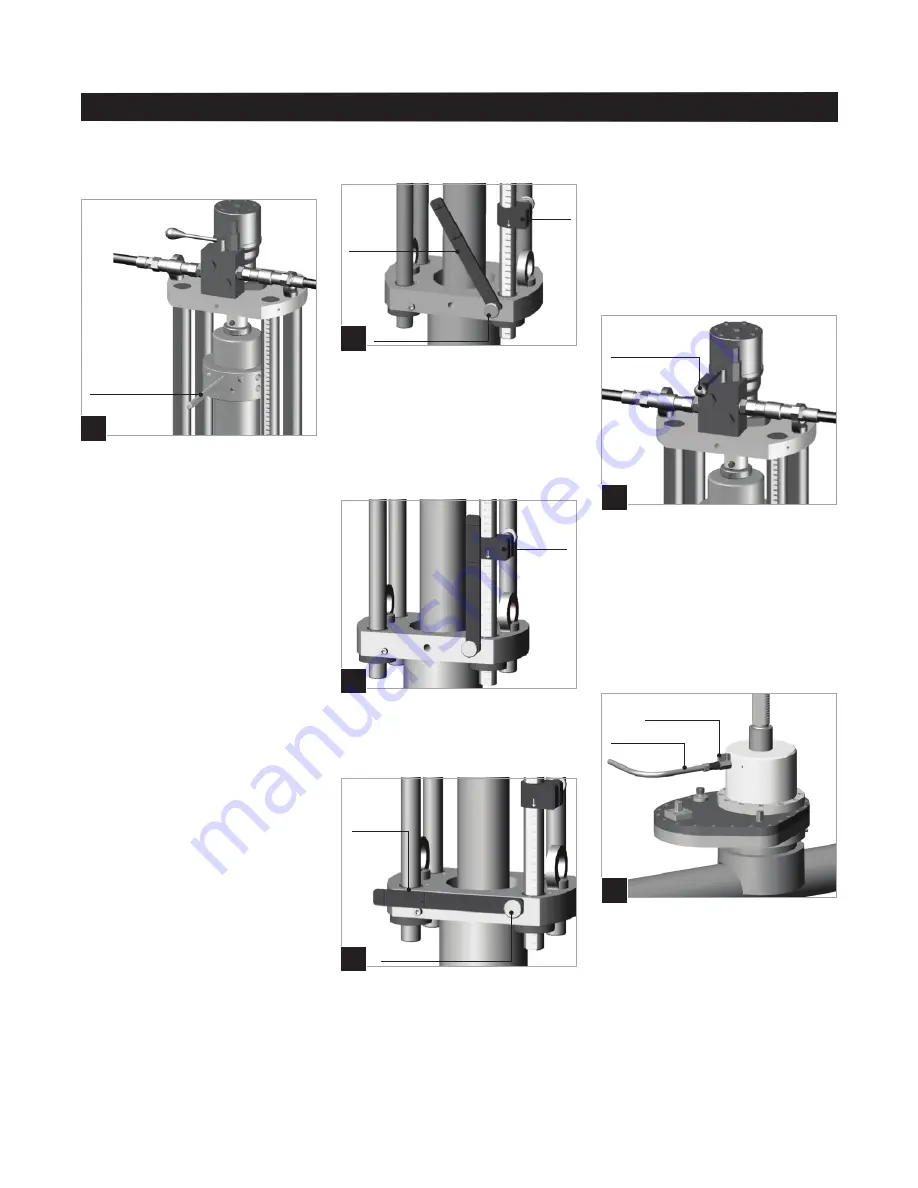

24. Return the hydraulic distributor

lever to the neutral position (

L.

)

25. Turn off the hydraulic power and

turn off the hydraulic control unit.

26. Remove the removable handle.

27. Turn the feed screw counter-

clockwise until the shell cutter is

inside of the drilling bell.

28. Close the slide gate valve.

29. Attach relief piping (

M.

).

30. Purge the residual pressure

above the closed gate a suitable

distance from possible sources of

ignition.

31. Remove hoses from the

hydraulic control unit and operator.

32. Remove the drilling machine.

M.

Flexible Pipe

Bleed Valve

L.

Lever in

Neutral

K.

Graduated

Scale

Knob

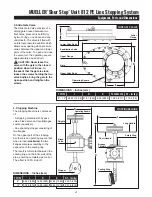

i.

Collar

Graduated

Scale

Knob

h.

Advancement

of the shell

cutter,

adjusted using

the removable

handle