Mueller E-Star OESE 7.5 and 9 HP HFC Condensing Unit

Installation and Operation Manual, Part No. 8828748

Effective June 16, 2020

5.1

THERMAL EXPANSION VALVE (TEV) SELECTION AND INSTALLATION

The condensing unit’s TEV must be field adjusted to maintain the milk cooler evaporator’s superheat at 4–6°F

(2.2–3.3°C) or the chiller evaporator’s superheat at 10–12°F (5.6–6.7°C). Proper location and sizing of the thermal

expansion valve is critical. Refer to Section 5.2 for the superheat adjustment procedure.

An externally equalized TEV must be used on Mueller milk cooling applications. A sight glass must be installed at

the TEV inlet.

See Table 7 for expansion valve selection.

TABLE 7: THERMAL EXPANSION VALVE SELECTION

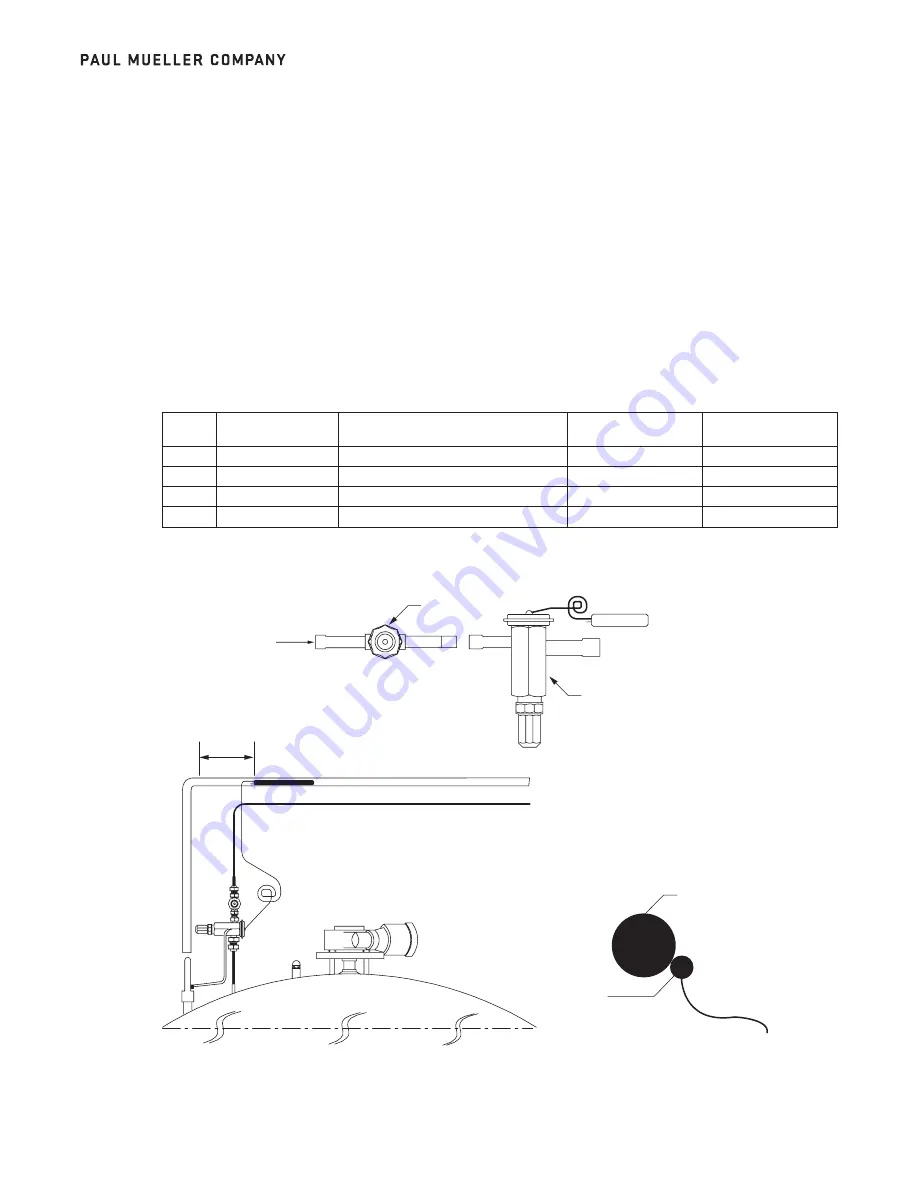

FIGURE 3: THERMAL EXPANSION VALVE INSTALLATION

10

Section 5.0 – Expansion Valve

No.

Description

Specifications

Part No. for Milk

Cooler Applications

Part No. for

Chiller Applications

1

R-507 TEV (7.5 HP)

1

⁄

2

" ODF inlet x

7

⁄

8

" ODF outlet

8825838

N/A

2

Sight Glass (7.5 HP)

1

⁄

2

" ODF inlet x

1

⁄

2

" ODF outlet solder

8824494

N/A

3

R-507 TEV (9 HP)

5

⁄

8

" ODF inlet x

7

⁄

8

" ODF outlet

8825840

8825850

4

Sight Glass (9 HP)

1

⁄

2

" ODF inlet x

1

⁄

2

" ODF

9813636

9813636

The TEV sensing bulb should be located

a minimum of 10 tube diameters away

from any fittings or bends.

Example:

7

/

8

" suction line (x) 10 = 8

3

/

4

".

Securely mount and insulate the TEV sensing

bulb at a 4-o’clock position on the copper

suction line. Horizontal mounting is always

recommended when possible. If vertical

mounting is required, maintain the minimum

dimensions as stated above.

4 o'clock

12 o'clock

1

2