6

CENTURY, B-50-B18 AND B-50-B24 FIRE HYDRANTS

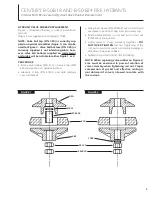

Hydrostatic Test, Storz Adapter and Storz Nozzle Installation

HYDROSTATIC TEST

• Remove a cap and open hydrant so barrel fills with

water. Replace cap and open hydrant fully.

• NOTE any leakage at:

1. ground line (traffic connection);

2. bearing housing connection;

3. nozzle to barrel connections;

4. cap gaskets.

• Use aquaphone or other leak detection device to

verify that there is no leakage below ground.

100 MM STORZ ADAPTER – INSTALLATION

Storz adapter is supplied with the following items:

• 100 mm Storz x female nozzle thread adapter;

• set screws;

• 2 adapter gaskets (

1

/

8

” thick and

1

/

16

” thick).

Orientation of Storz lugs should be approximately

vertical (Figure 3) to permit proper drainage (to avoid

build-up of ice in "pockets”). The following assembly

procedure is recommended:

• Inspect end face of pumper nozzle. Remove any

burrs etc. that could damage adapter gasket.

• Insert

1

/

16

” thick gasket only in Storz adapter and

thread adapter onto pumper nozzle.

• "Snug'' into position (using bar as illustrated in

Figure 3), but

do not over tighten

.

• Note orientation of lugs. If acceptable, complete

tightening of Storz adapter. If not acceptable,

repeat using

1

/

8

” gasket or

1

/

8

” +

1

/

16

” if necessary.

• Tighten set screws sufficiently to permit assembly of

cap to outlet.

• Pressurize hydrant to verify adapter to pumper

nozzle joint – retighten adapter if required.

• Remove set screws and run drill point into nozzle

(use

5

/

16

” drill). Replace set screws.

STORZ NOZZLE INSTALLATION –

CENTURY/B-50B TYPE HYDRANT

This procedure applies to hydrants with model desig -

nation Century, B-50-B18, B-50-B24 and B-50-BM.

NOTE: Replacement, as described in this pro -

cedure, can only be performed on resilient seated

pumper nozzles. Leaded-in type nozzles can be

converted by utilizing a Storz adapter that threads

onto the existing pumper nozzle.

PROCEDURE

• Remove pumper cap.

• Insert hydrant pumper nozzle wrench through

pumper nozzle. Wrench is inserted completely

through nozzle and pulled back to engage pocket

on wrench with lugs on nozzle retainer.

• Turn wrench handle in a

clockwise

direction (facing

nozzle). Continue turning while pulling lightly on

wrench (to maintain engagement} until nozzle

disengages retainer.

• Slide nozzle toward handle, reach into pumper port

with one hand to hold retainer in position and

remove wrench.

• Drop pumper nozzle from wrench, pick up Storz

connector with wrench and re-engage wrench with

lugs on nozzle retainer.

Position Storz connector in recess in upper barrel-lugs

on Storz engage pockets in upper barrel recess.

Turn wrench in

counter-clockwise

direction to

tighten Storz connector into position. Threading can

be started by turning wrench with one hand on

wrench shaft while positioning Storz connector with

other hand. After thread has started, tighten firmly.

FIGURE 3

20°

20°

Summary of Contents for B-50-B18

Page 7: ...7 CENTURY B 50 B18 AND B 50 B24 FIRE HYDRANTS Notes...

Page 8: ......