Mueller Model D Fre-Heater Installation and Operation Manual

Effective March 1, 1993

Part No. 8800430

Revised November 6, 2019

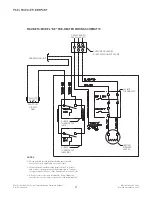

FIGURE 8: TYPICAL MULTIPLE-UNIT PARALLEL PLUMBING FOR FRE-HEATERS

FIGURE 9: FRE-HEATER PIPING SCHEME

9

Hot

Water

Outlet

Pressure

Temperature

Relief

Valve

N.O.

Gate

Valve

N.O.

Drain

Cold Water Inlet

Mueller

Fre-Heater

Check

Valve

Mueller

Fre-Heater

Circulating Pump

Conventional

Water

Heater

Hot

Water

Loop

Check Valve

Mueller

Fre-Heater

Cold

Water

Inlet

Circulating Pump

Booster

Heater

Loop

Check Valve

Mueller

Fre-Heater

Cold

Water

Inlet