8

Installation of Tandem Stems

Some gates have wide openings

with relatively short gate heights.

When the installation drawings

show tandem lifts, install each lift

in accordance with the preceding

steps 1 – 5. After each lift has

been installed and each stem is

connected to the gate slide at

the bottom and the lift at the top,

proceed as follows:

1.

Turn the input shaft of each lift

in the direction to open the gate

until each stem makes firm contact

with the top of its connection on

the gate slide.

2.

Place a level on the top of the

gate slide and move one stem or

the other of the gate up or down

until the slide is completely level.

3.

A tandem interconnecting shaft

is furnished to connect the two lifts

and cause them to act in unison

for raising or lowering the gate.

Loosen the fasteners on one of

the jaws of the flexible coupling

and slide it toward the center of

the shaft until the shaft can be

connected between the two lifts.

Complete the connection and

retighten all fasteners.

4.

Move the gate slide up and

down by turning the input shaft

of one lift. Ensure the gate is

installed with its top level and that

the gate is moving freely.

5.

Complete the installation of

any stem guides, lubricate the

stem, adjust the stop nuts, etc, as

described in the preceding steps

1 – 9 in the section entitled Lift

Installation and Adjustment of

Stem Guides for gates not self-

contained.

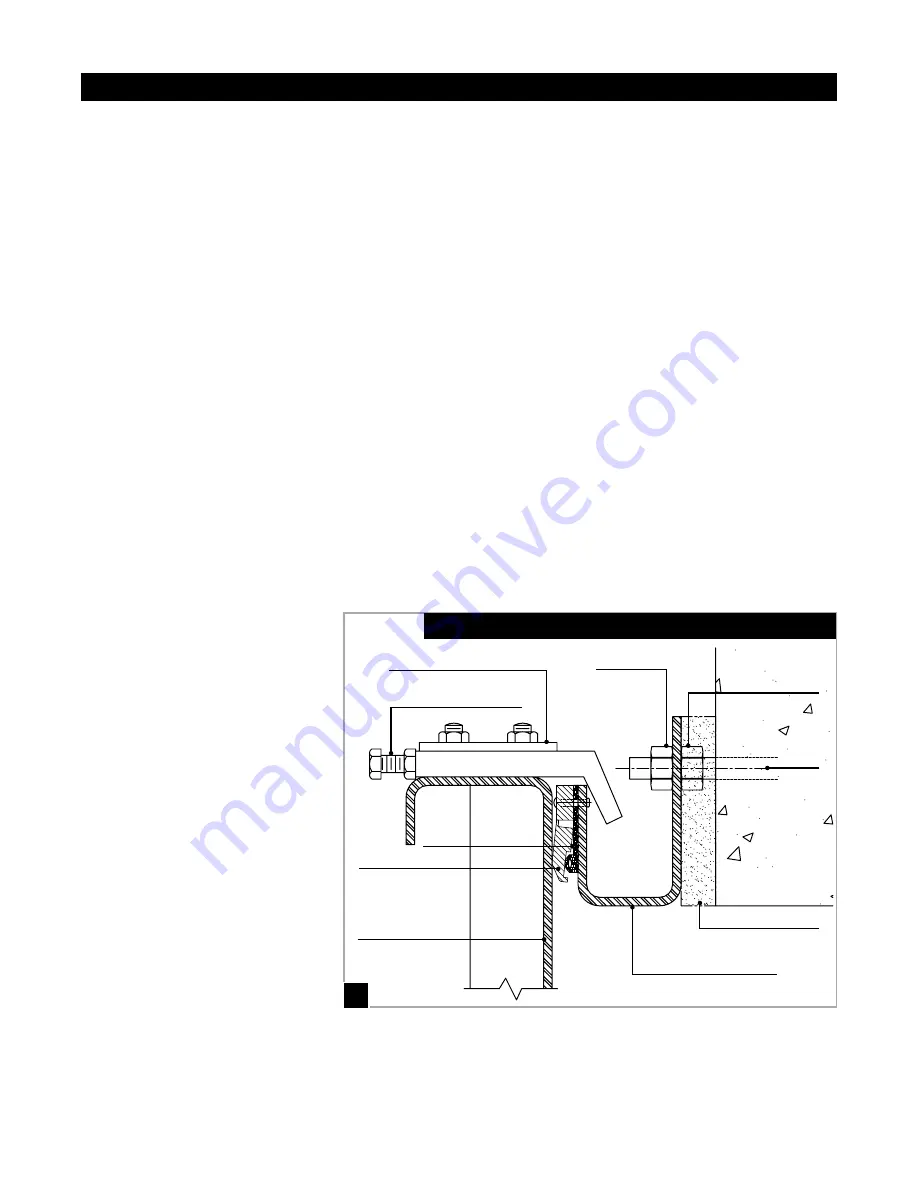

Gate Adjustment

This gate is equipped with low-

friction polyethylene (UHMWPE)

seats and guides. The seats

rest on a neoprene (rubber) pad

for cushioned gasketing to the

frame. Sealing at the side is

accomplished by pinching the

seal lips against the slide plate

using the compression of the

rubber gasket pad. Top horizontal

member seal (and also bottom, if

seals are 4-sided) are loaded by

the compression pad and assisted

with ensured hook-type wedges

on medium and larger width gates

(Fig. A & J).

This gate has been factory

adjusted. However, if the shake-

proof nuts have been loosened,

readjustment may be required.

Visual Tightness of the Seat

against the Side

No light should be visible through

the seat or measurable gaps

between the slide plate and the

seat. A .004" gauge may be

used to check the seat gap as a

starting point; however, the best

test and proof of performance

is an unseating hydrostatic

test. This gate is required to

comply with AWWA C561 leakage

specifications.

HG561 FABRICATED SLIDE GATE

Installation

9

J.

Gate Frame

Grout

Anchor

Slide Plate

SIDE VIEW OF BOTTOM SECTION SHOWING SEAL ARRANGEMENT

Wedge Adjustment Bolt

Adjusting Nut

Top Nut

UHMW

Polymer

Seal

Neoprene Load Pad

Cast Stainless Steel Wedge