2

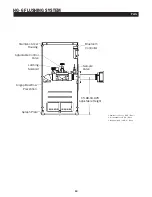

Stainless Steel

Housing

Adjustable Control

Valve

Latching

Solenoid

Bluetooth

Controller

Sample

Valve

15.88-18.625

Adjustable Height

Airgap Backflow

Prevention

Splash Plate

HG-6 FLUSHING SYSTEM

Installation Instructions

GENERAL

INSTALLATION

Please read and retain this

manual. It will be helpful for

future reference, training,

troubleshooting, and maintenance.

Site Evaluation

Each installation is unique and

will require a minimum of advance

planning. Prior toinstallation, the

drainage patterns for the intended

installation location should be

reviewed. The drainage pattern

must permit discharged water to

Overview

The Hydro-Guard HG-6 Hydrant-

Based Flushing System is a

portable and emergency use device

designed to flush water lines from

fire hydrants located anywhere in

the distribution network. These

devices require the hydrant to be

live when programmed for flushing.

The HG-6 has been engineered and

manufactured to provide outstanding

dependability and performance.

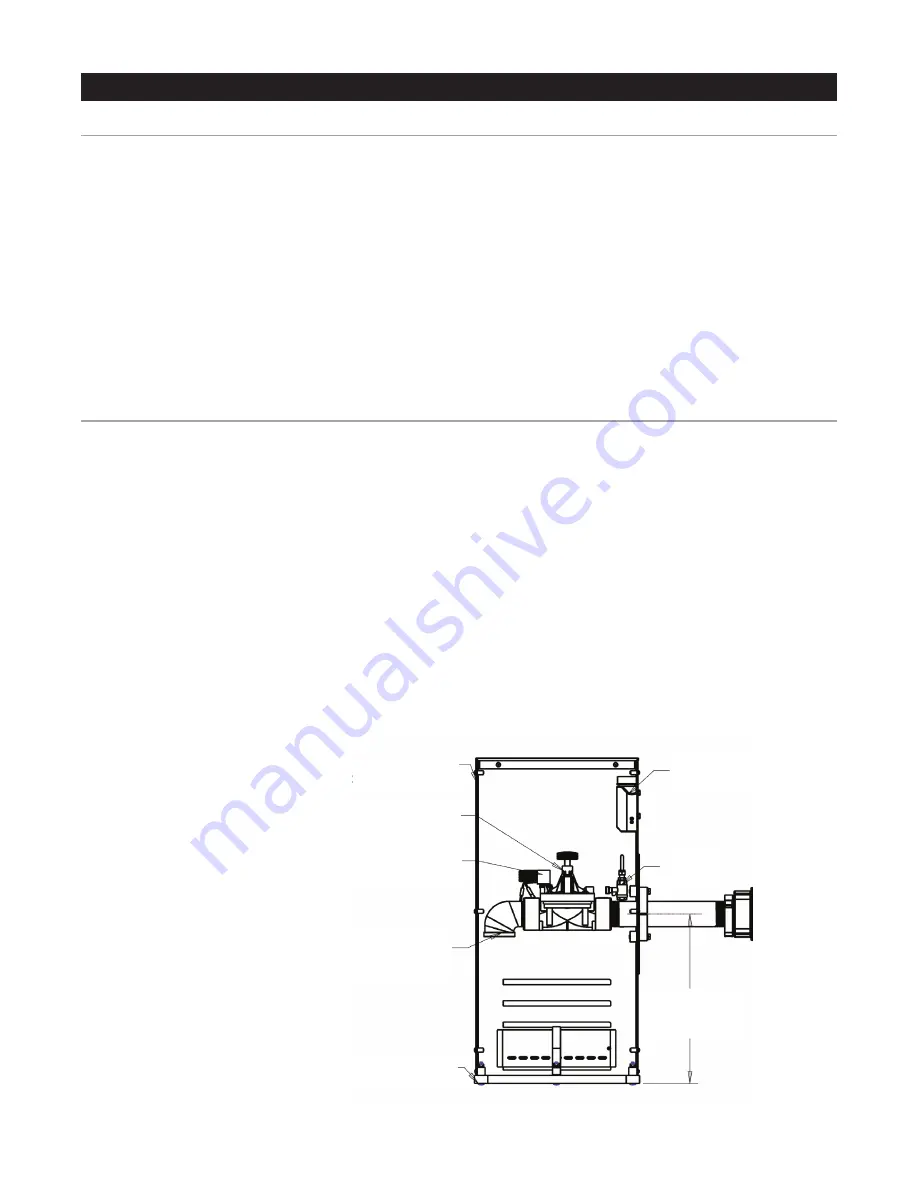

1.

Remove the Hydro-Guard Unit

from its packaging and inspect

for possible damage during

shipping.

2.

Using the pumper nozzle, flush

hydrant for several minutes to

ensure the water flow is free of

debris (i.e., rocks, etc.)

3.

Confirm hydrant is turned off.

4.

Gather 2" NTP connector and

hydrant wrench.

5.

If necessary, loosen but do not

remove the four bolts on the

side of the Hydrant Flusher

in order to adjust connection

height, ensuring the device is

supporting its own weight. Once

proper height is determined,

tighten the four height

adjustment bolts.

6.

Connect the Hydro-Guard Unit

by means of the 2" threaded

nipple and supplied hose

adapter.

7.

Open the hydrant’s valve in

order to charge the hydrant.

flow away from the Hydro-Guard

Unit or to be absorbed by the

surrounding soil. The Unit’s ground-

level erosion controlling splash

plate is designed to disperse the

water energy from the discharging

water and reduce the risk of

erosion from around the base of

the fire hydrant. In order to prevent

undue pooling of the effluent water,

multiple nightly flushes are effective

in managing discharge volumes.

8.

If the HG-6 has been shipped

with the Dechlorination System;

remove the security screws at

side of unit to access, remove the

dechlorination chamber, open, fill

with sodium sulfite or ascorbic

acid tablets, reinsert and replace

security screw.

9.

Disinfect the Hydro-Guard

Automatic Flushing Device in

accordance with the utility’s policy.

Do not exceed the dosage and

contact times recommended

by the American Water Works

Association.

10.

The Hydro-Guard Automatic

Flushing Device may now be

programmed and placed

into service.

Summary of Contents for Hydro-Guard HG-6

Page 11: ...11 Notes HG 6 FLUSHING SYSTEM...