Bakery Chiller Models PMC 40/50 and PMC 70/120

Effective February 23, 1999

Installation and Operation Instructions, Part No. 9842311

Revised May 7, 2009

7.5

Thermal Expansion Valve (TEV) Superheat Adjustment (Continued)

3.

Utilizing an R-22 or R-507 Pressure Temperature Chart, convert the suction pressure reading from

Step 1 to saturation temperature.

4.

The superheat value is found by subtracting the saturation temperature determined in Step 3 from

the actual suction line temperature taken in Step 2.

5.

If the superheat is not in the range of 8 to 10°F, at conditions as described above, adjust the TEV.

6.

If the superheat is below 8°F, turn the TEV’S adjustment stem clockwise

1

/

8

to

1

/

4

of a turn. Allow

the system to operate for 5 minutes before repeating test.

7.

If the superheat is above 10°F, turn the TEV’s adjustment stem counterclockwise

1

/

8

to

1

/

4

of a turn.

Allow the system to operate for 5 minutes before repeating test.

8.

Any time adjustment is made to the TEV, the refrigerant charge should be checked.

9.

Check the superheat setting and make final adjustments at a product temperature near setpoint for

best performance.

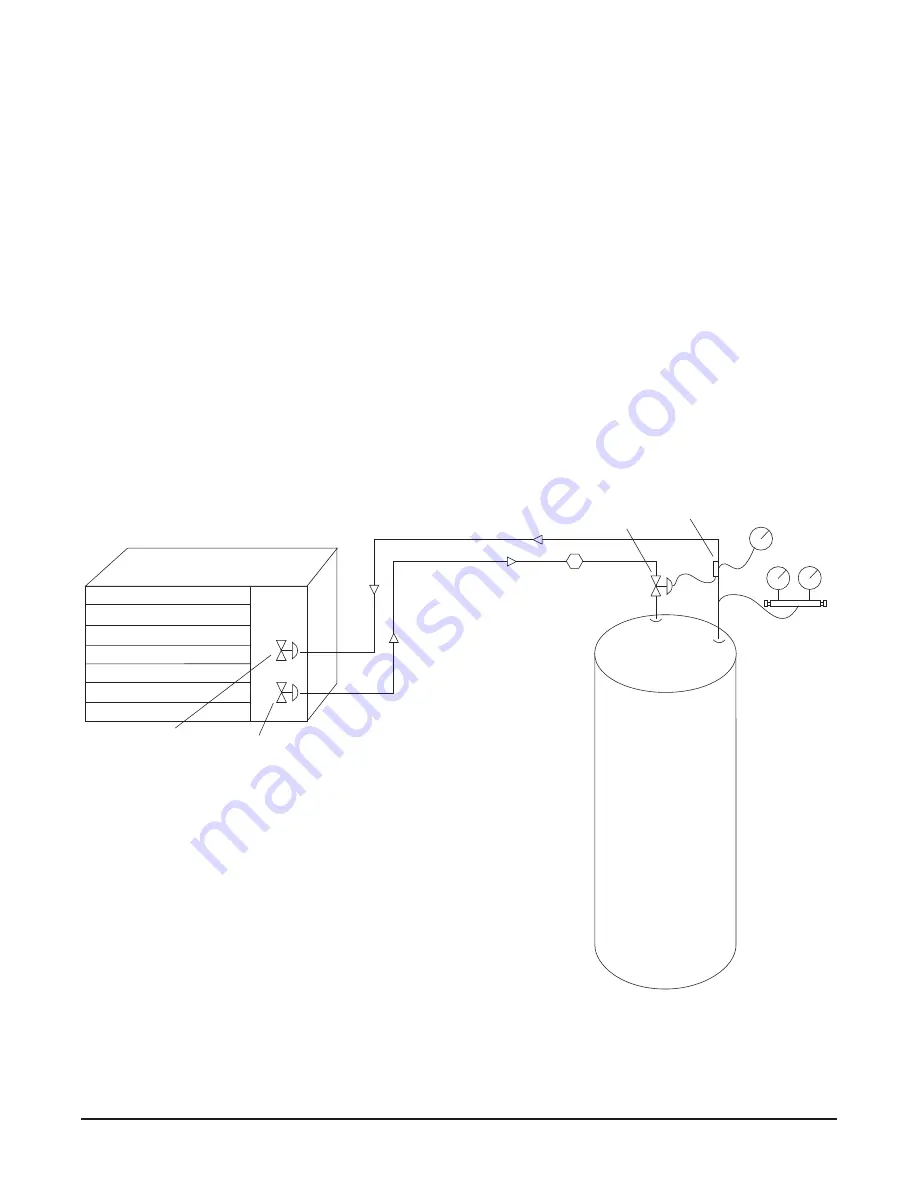

7.6

Thermal Expansion Valve Superheat Adjustment Diagram

18

TEV

Sensing Bulb

Thermometer

Suction Gauge

Liquid Line

Sight Glass

Thermostatic

Expansion

Valve

Liquid Line

Service Valve

Suction Line

Service Valve

Bakery Chiller

Air-Cooled Condensing Unit

Suction Line

Liquid Line